Simrad SP70

156

850--164186 A

5 MAINTENANCE

5.1 Introduction

This section deals with maintenance work that may be carried out

by the user. In addition to cleaning the cabinets and dust filters,

the user should inspect the sonar room at least once a week. The

ventilation and heating system, as well as the bilge pump

arrangement should then be checked to be in good working order.

The spare part box which is delivered with the sonar, contains

fuses for the complete sonar. For location and replacing of these,

refer to the chapter for the unit in question.

Major repairs and complete overhaul of the sonar, should be left

to an authorized Simrad service engineer.

5.2 Wheelhouse units

Cleaning

The units should be kept clean and dry. Remove salt water residue

with a soft cloth which has been moistened in fresh water. Do not

use strong solvents.

Note ! The display screen should be handled with care to avoid damaging the

anti-glare filter coating. Use a soft cloth without any strong solvents

when cleaning it.

Dust filter

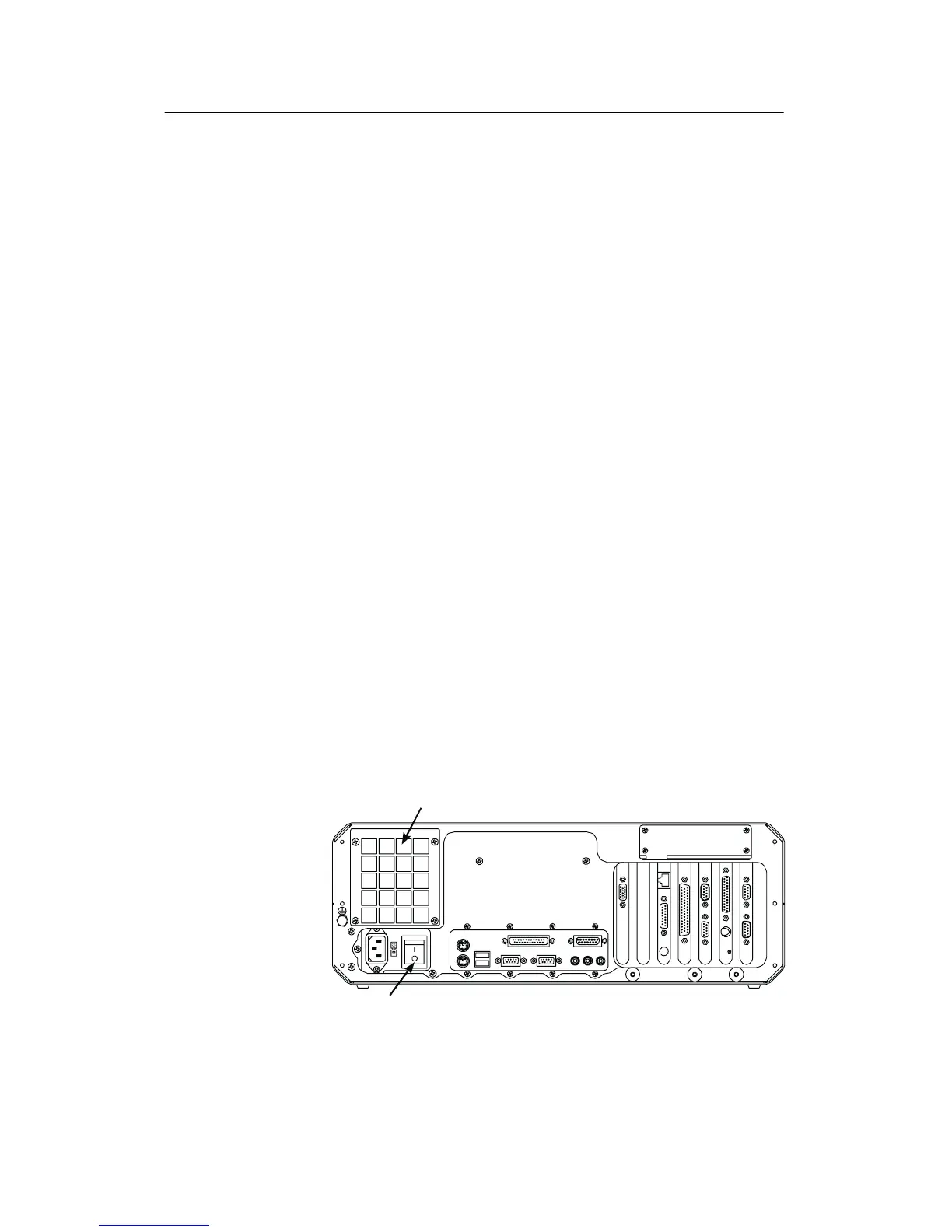

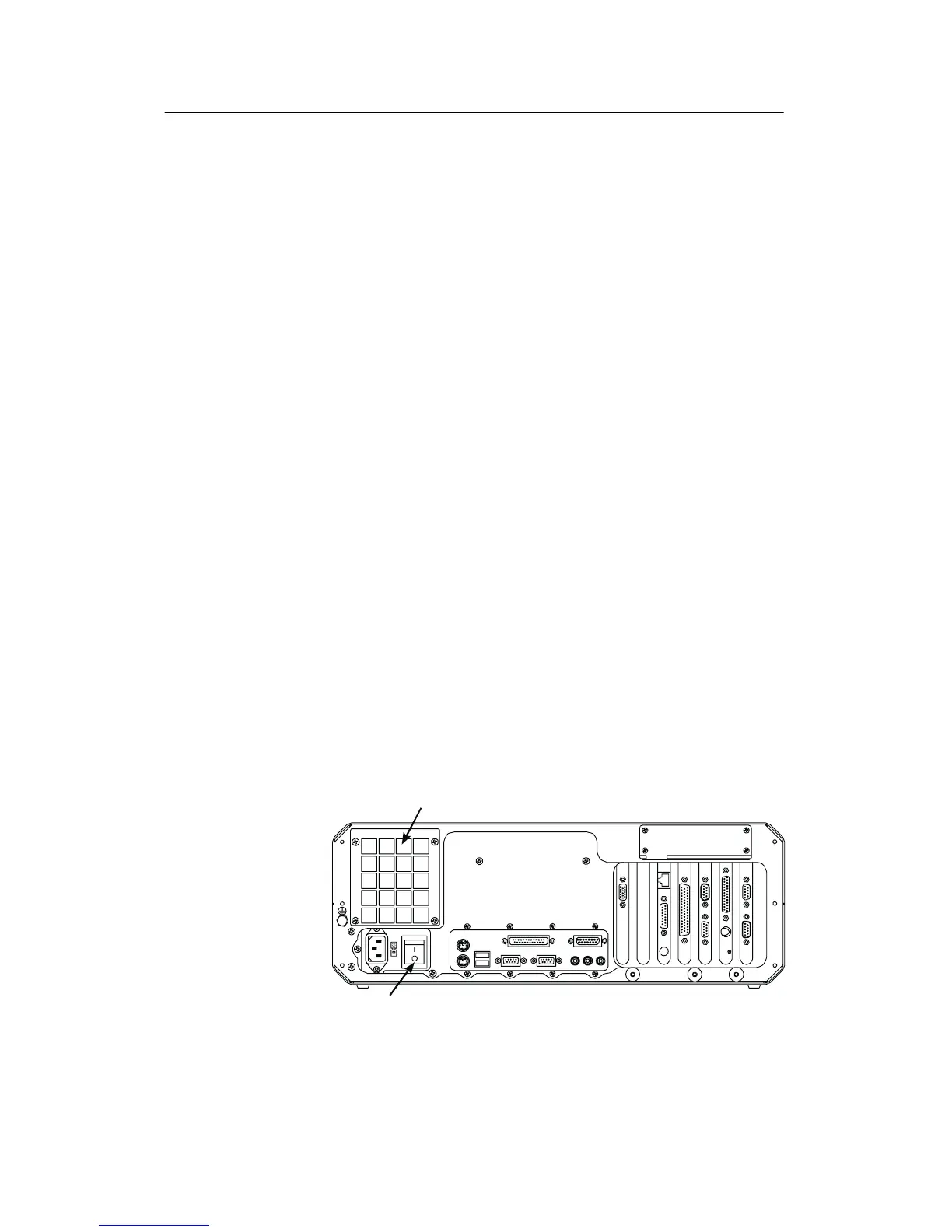

There is a dust filter on the air inlet at the rear side of the Processor

Unit. To avoid overheating, this should be inspected, and if

necessary, cleaned once every third month.

Figure 154 - Rear side of t he Processor Unit

SIMRAD

S102

(CD5880A)

Dust filter

The filter is accessible by unscrewing the four screws which fasten

the filter grid. The filter should be vacuum cleaned, or washed in

soap and water. If washed, the filter must be dried thoroughly

before being reinstalled.

Loading...

Loading...