Section04ENGINE

Subsection 05 (PTO HOUSING)

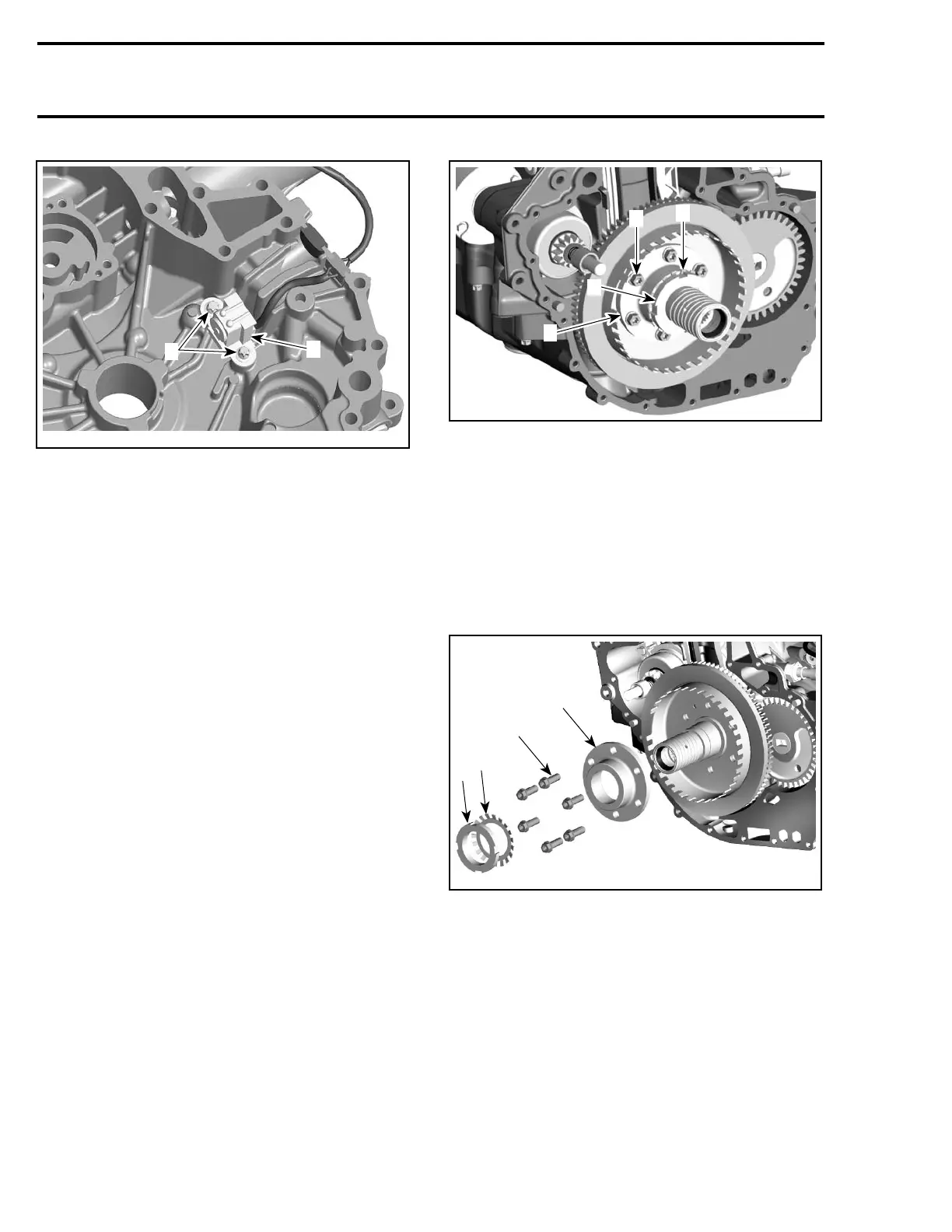

R1503motr341A

1

2

1. CPS screws

2. CPS

Inspection

Check CPS condition. If damaged replace the

faulty part.

For electrical inspection, refer to ENGINE MAN-

AGEMENT for the CPS.

Installation

For installation, reverse the removal procedure.

However, pay attention to the following.

NOTE: Apply Loctite 243 on threads. Torque CPS

screwsto10N•m(89lbf•in).

ADAPTER SLEEVE AND FLANGE

COUPLING

Removal

Lock crankshaft with locking tool (P/N 529 035

821). Refer to CRANKSHAFT LOCKING in EN-

GINE BLOCK subsection.

Remove:

– PTO housing

– nut no. 15 using 4-tooth sprocket (P/N 529 035

960)

– retaining ring with lug no. 16

– hexagonal screws no. 17

– flange coupling no. 18.

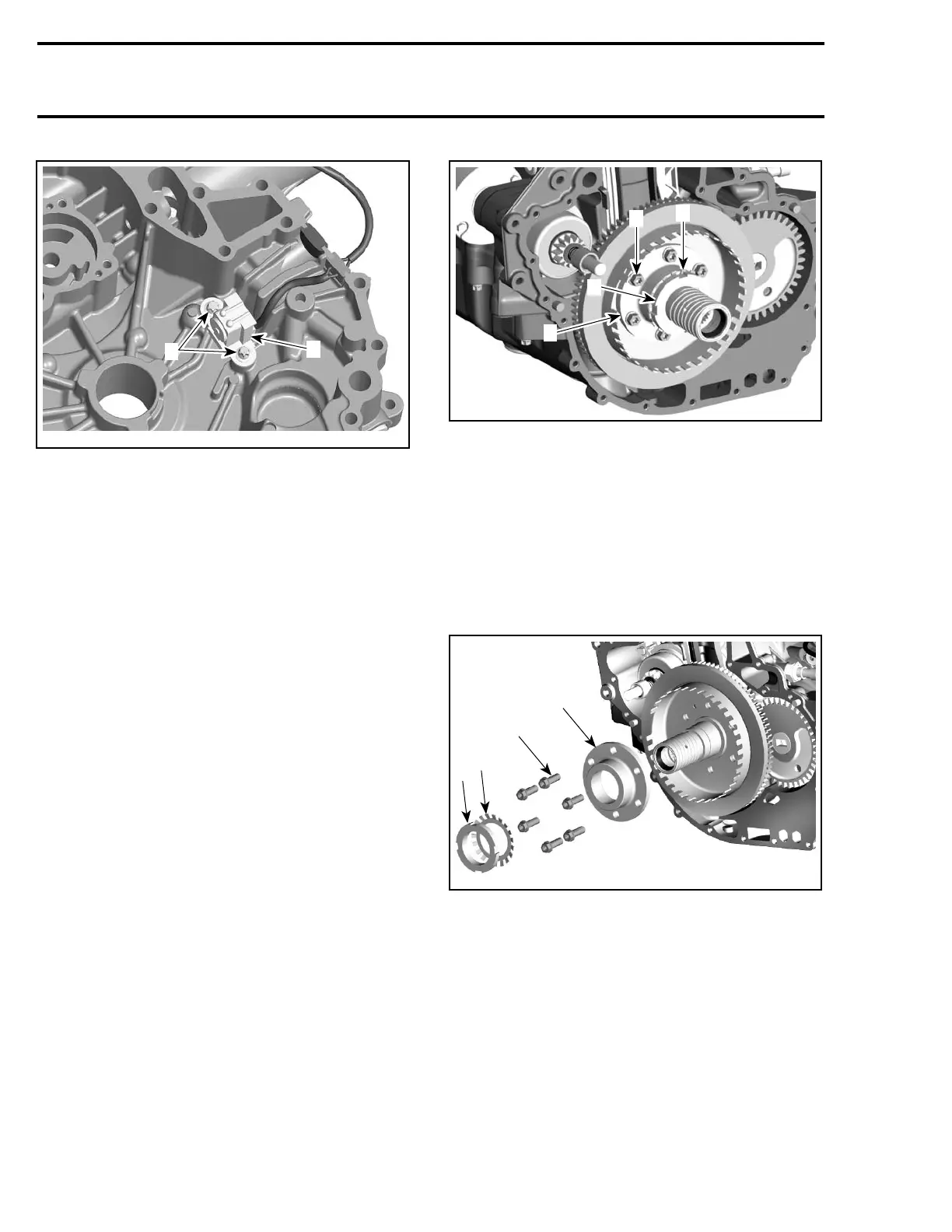

R1503motr342A

2

3

1

4

1. Nut

2. Retaining ring with lug

3. Hexagonal screws

4. Flange coupling

NOTE: Carefully remove the flange coupling

no. 18 using torque flange remover (P/N 529 035

958).

Inspection

Check nut, retaining ring with lug and flange cou-

pling condition. If damaged, replace faulty part.

4

R1530motr343A

1

2

3

1. Nut

2. Retaining ring with lug

3. Hexagonal screws

4. Flange coupling

Installation

For installation, reverse the removal procedure.

However, pay attention to the following.

Use Loctite 243 on the cone at the flange coupling,

push flange coupling on adapter sleeve and align

the hole pattern. Apply Loctite 243 on threads.

Tighten the hexagonal screws and nut by hand to

help centering. First torque hexagonal screws to

24 N•m(18lbf•ft).

92 Te m plat e

Loading...

Loading...