Section04ENGINE

Subsection 05 (PTO HOUSING)

A32C0RA

1

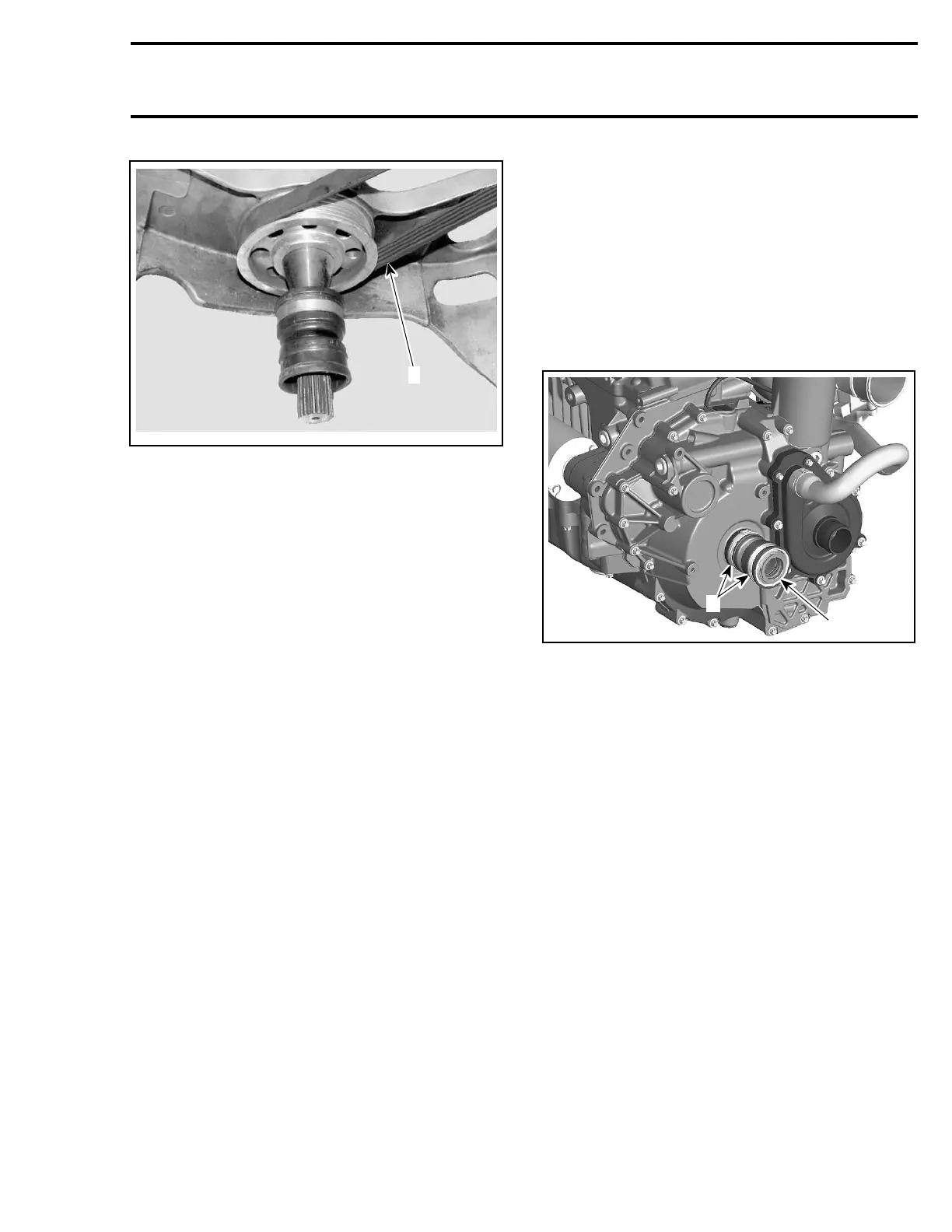

SEAL CARRIER INSTALLED ON DRIVE SHAFT

1. Alternator belt loosely installed

Loosely install a new collar on the seal carrier.

Reinstall engine support (with drive shaft).

NOTE: While installing engine support, turn drive

shaft to mesh splines.

Fasten the new collar to secure seal carrier boot

to PTO housing.

Secure engine support to engine block first, then

secure to engine mounts.

Refill engine with oil. Refer to ENGINE section.

Align drive and driven pulleys. Refer to TRANS-

MISSION.

Adjust alternator belt tension. Refer to ELECTRI-

CAL SYSTEM.

PTO SEAL

Inspection

Check the PTO seal no. 22 and O-rings no. 10 on

the PTO housing. If brittle, hard or damaged, or if

you see a sign of oil leakage, replace it.

Removal

NOTE: When drive shaft will be removed, some

oil will flow out. To prevent it, start engine, run at

4000 RPM for 10 seconds and stop engine at this

RPM. This will move oil out of PTO housing into

oil tank.

CAUTION: Never run engine without being

connected to the cooling system.

Place a small pan under PTO housing to prevent

spillage. If spillage occurs, clean immediately

with the pulley flange cleaner (P/N 413 711 809)

to prevent oil stains.

Remove:

– engine support (with drive shaft). See above in

PTO HOUSING

– Oetiker clamp no. 11 located close to the PTO

housing

– PTO seal no. 22.

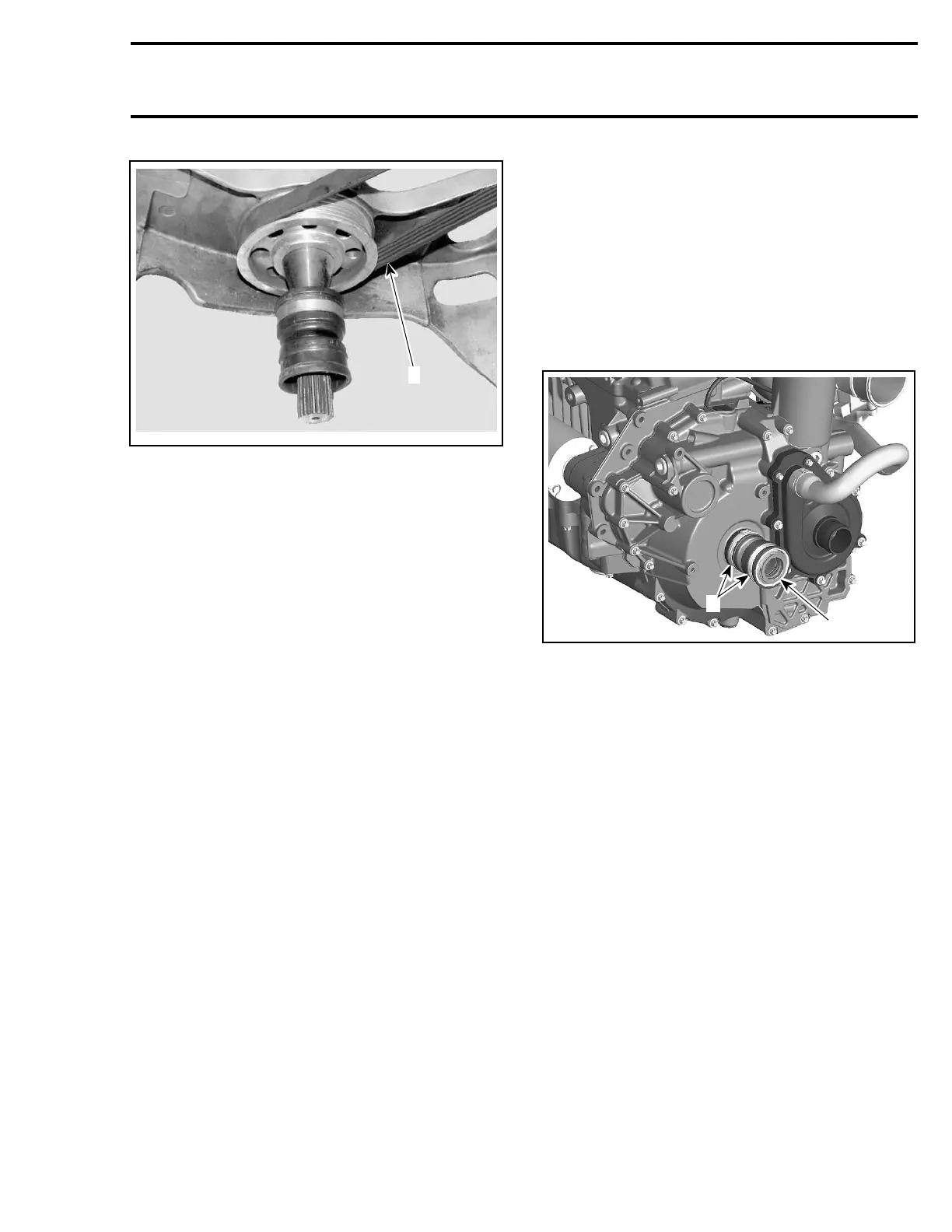

2

R1503motr340A

1

1. Oetiker clamps

2. PTO seal

Installation

Reinstall removed parts in the reverse order.

CPS

Removal

Remove:

– PTO housing (refer to PTO HOUSING RE-

MOVAL elsewhere in this section)

– screws no. 14

– grommet on CPS cable from housing

– CPS.

Te m pla te 91

Loading...

Loading...