Section07ELECTRICALSYSTEM

Subsection 03 (ELECTRIC STARTER)

PARTS INSPECTION

Armature

NOTE: An ohmmeter may be used for the follow-

ing testing procedures, except for the one con-

cerning shorted windings in armature.

Check commutator for roughness, burnt or scored

surface. If necessary, turn commutator on a lathe,

enough to resurface only.

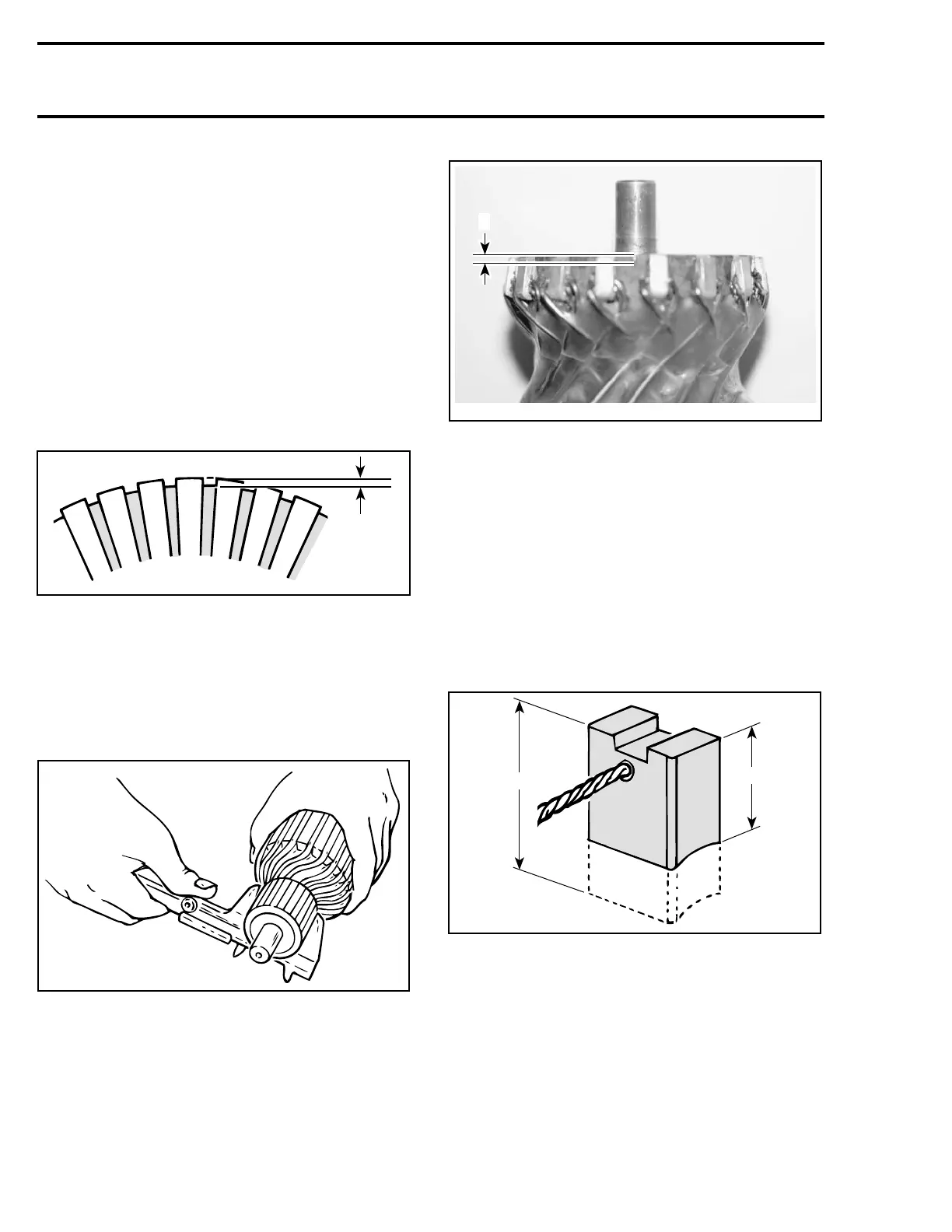

Check commutator for mica depth. If depth is less

than 0.20 mm (.008 in), undercut mica. Be sure

that no burrs are left and no copper dust remains

between segments after undercutting operation is

completed.

F01H0RA

1

1. Commutator undercut 0.20 mm (.008 in)

Check commutator out of round condition with

V-shaped blocks and an indicator. If commutator

out of round is more than 0.40 mm (.016 in), com-

mutator should be turned on a lathe.

Check commutator outer diameter. If less than

27 mm (1.063 in), replace.

A03E06A

Check commutator condition with an indicator. If

out of specification, replace the starter.

1

F18H0RA

1. Commutator undercut 0.20 mm (.008 in)

Brush Holder

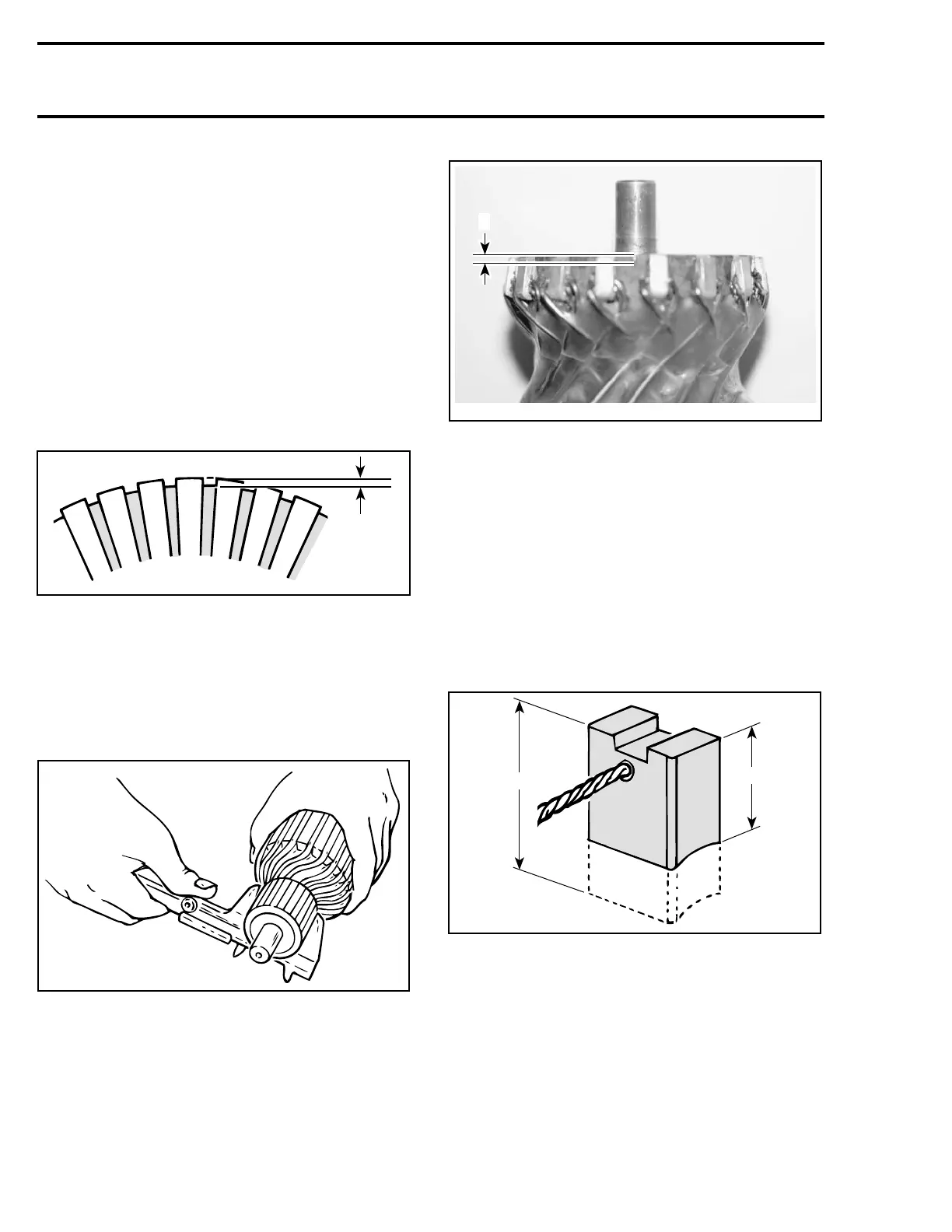

Check brush holder for insulation using an ohm-

meter. Place one test probe on insulated brush

holder and the other test probe on brush holder

plate. If continuity is found, brush holder has to

be repaired or replaced.

Brush

Measure brush length. If less than 8.5 mm

(.335 in), replace them.

NOTE: New brush length is 12 mm (.472 in).

A03E05A

1

2

1. New

2. Wear limit 8.5 mm (.335 in)

ASSEMBLY

Reverse the order of disassembly to reassemble

starter. However, attention should be paid to the

following operations.

258 Te m plat e

Loading...

Loading...