INTRODUCTION

NOTE: Avoid grinding.

– Clean both mating surfaces with solvent.

– Spray Loctite Primer N on both mating surfaces

andonbothsidesofgasket. Allowtodry1or

2 minutes.

– Apply gasket eliminator 515 (P/N 413 702 700)

on both sides of gasket, using a clean applicator.

– Place gasket on mating surfaces and assemble

immediately.

NOTE: If the cover is bolted to blind holes (above),

apply proper strength Loctite in the hole and on

threads. Tighten.

If holes are sunken, apply proper strength Loctite

on bolt threads.

– Tighten as usual.

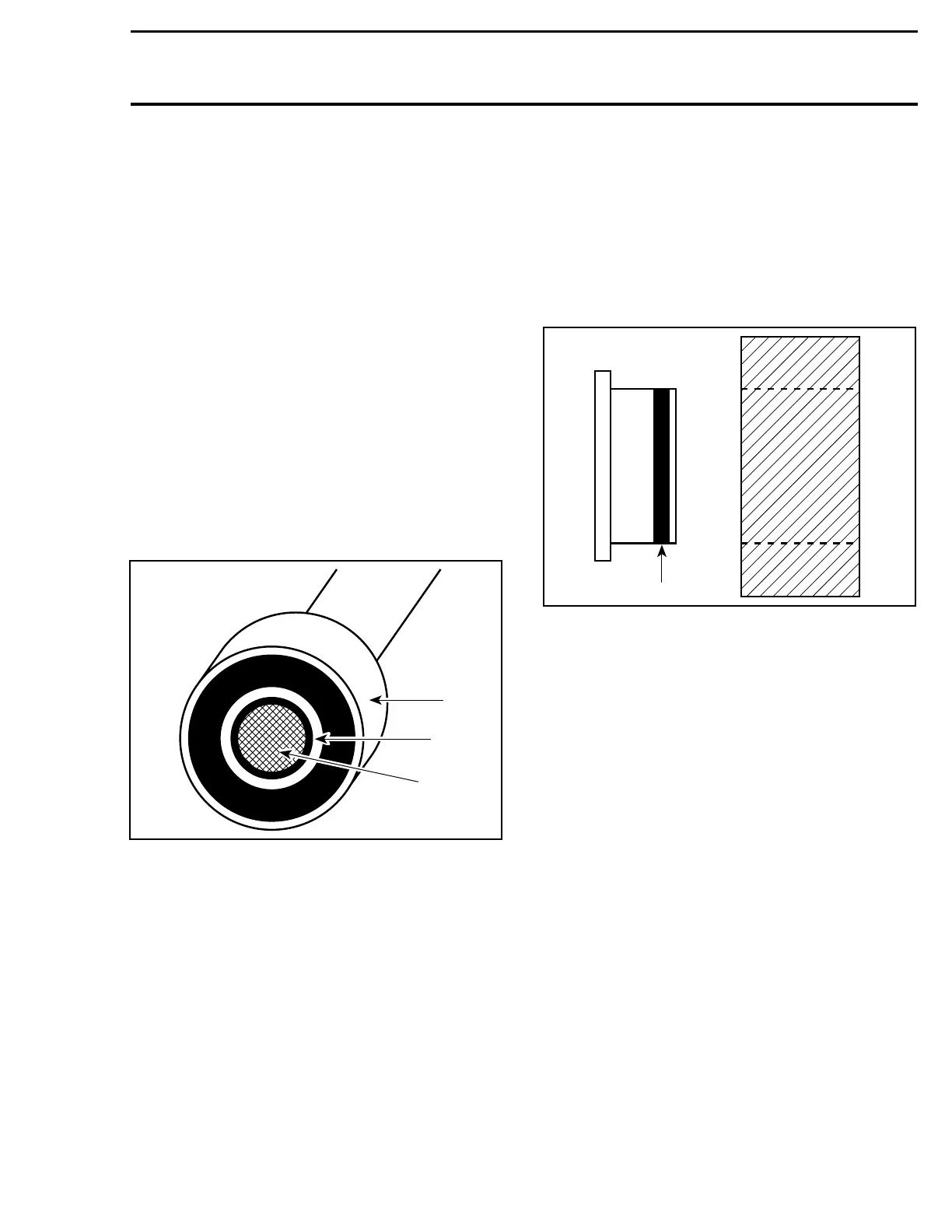

MOUNTINGONSHAFT

Mounting with a Press

A00A3UA

1

2

3

1. Bearing

2. Proper strength Loctite

3. Shaft

Standard

– Clean shaft external part and element internal

part.

– Apply a strip of proper strength Loctite on shaft

circumference at insert or engagement point.

NOTE: Retaining compound is always forced out

whenappliedonshaft.

– DO NOT use anti-seize Loctite or any similar

product.

– No curing period is required.

Mounting in Tandem

– Apply retaining compound on internal element

bore.

– Continue to assemble as shown above.

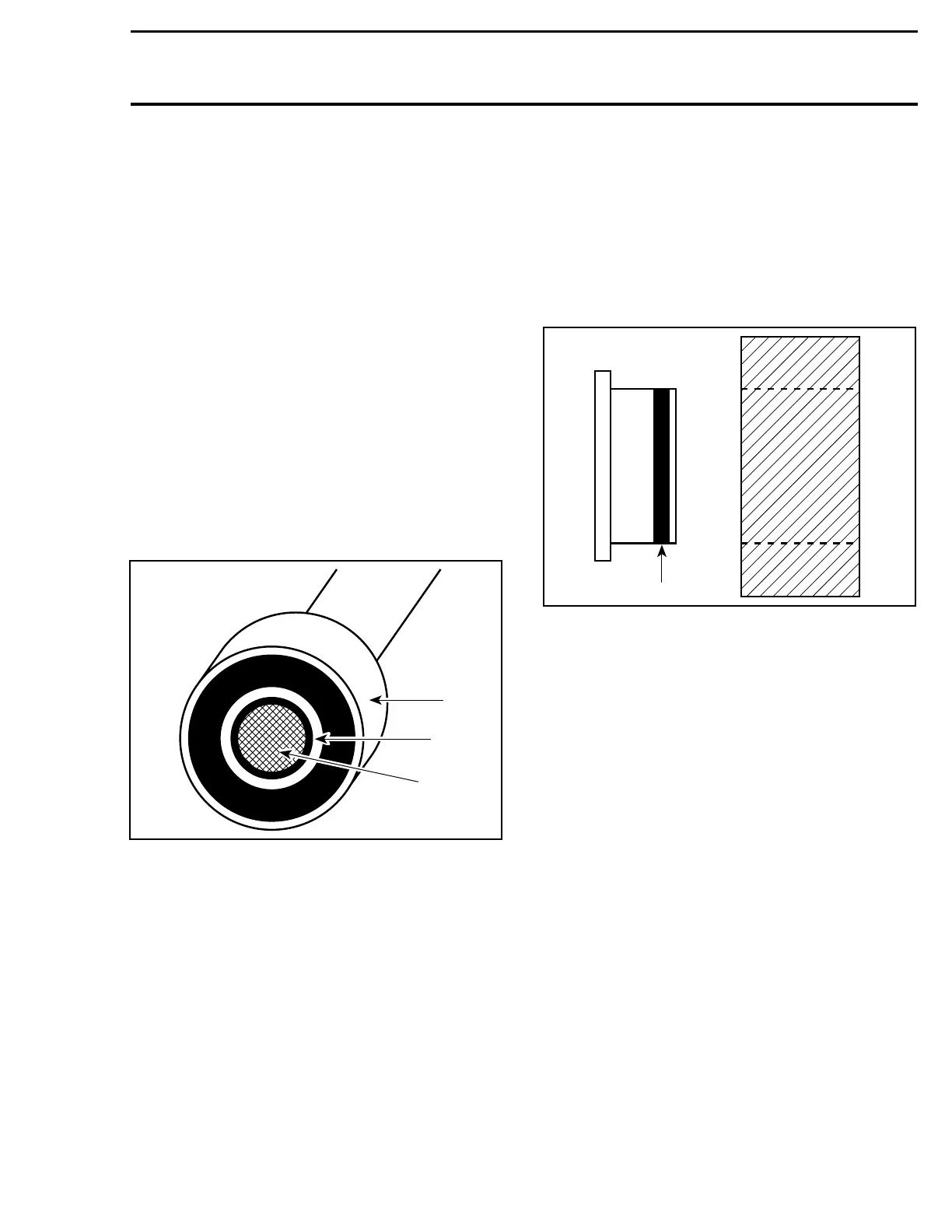

CASE-IN COMPONENTS

Metallic Gaskets

A00A3VA

1

1. Proper strength Loctite

– Clean inner housing diameter and outer gasket

diameter.

– Spray housing and gasket with Loctite Primer N

(P/N 293 800 041).

– Apply a strip of proper strength Loctite on lead-

ing edge of outer metallic gasket diameter.

NOTE: Any Loctite product can be used here. A

low strength liquid is recommended as normal

strength and gap are required.

– Install according to standard procedure.

– Wipe off surplus.

– Allow it to cure for 30 minutes.

NOTE: Normally used on worn-out housings to

prevent leaking or sliding.

It is generally not necessary to remove gasket

compound applied on outer gasket diameter.

XV

Loading...

Loading...