Section 06 TRANSMISSION

Subsection 01 (DRIVE BELT)

DRIVEBELTHEIGHT

MEASUREMENT AND

ADJUSTMENT

Measurement

NOTE: The drive belt height measurement must

be performed each time a new drive belt is in-

stalled.

NOTE: To obtain an accurate drive belt height

measurement, it is suggested to allow a break-in

period of 50 km (30 miles).

Before checking the belt height, ensure that a

good-condition proper belt (refer to the APPLICA-

TION CHART) is installed.

Adjust pulley distance and alignment. Refer to

PULLEY DISTANCE AND ALIGNMENT.

To obtain maximum vehicle performance, the belt

height must be adjusted according to specifica-

tions shown in the accompanying chart.

MODEL BELT HEIGHT

All models

Top edge of drive belt cord should be

flush with driven pulley edge.

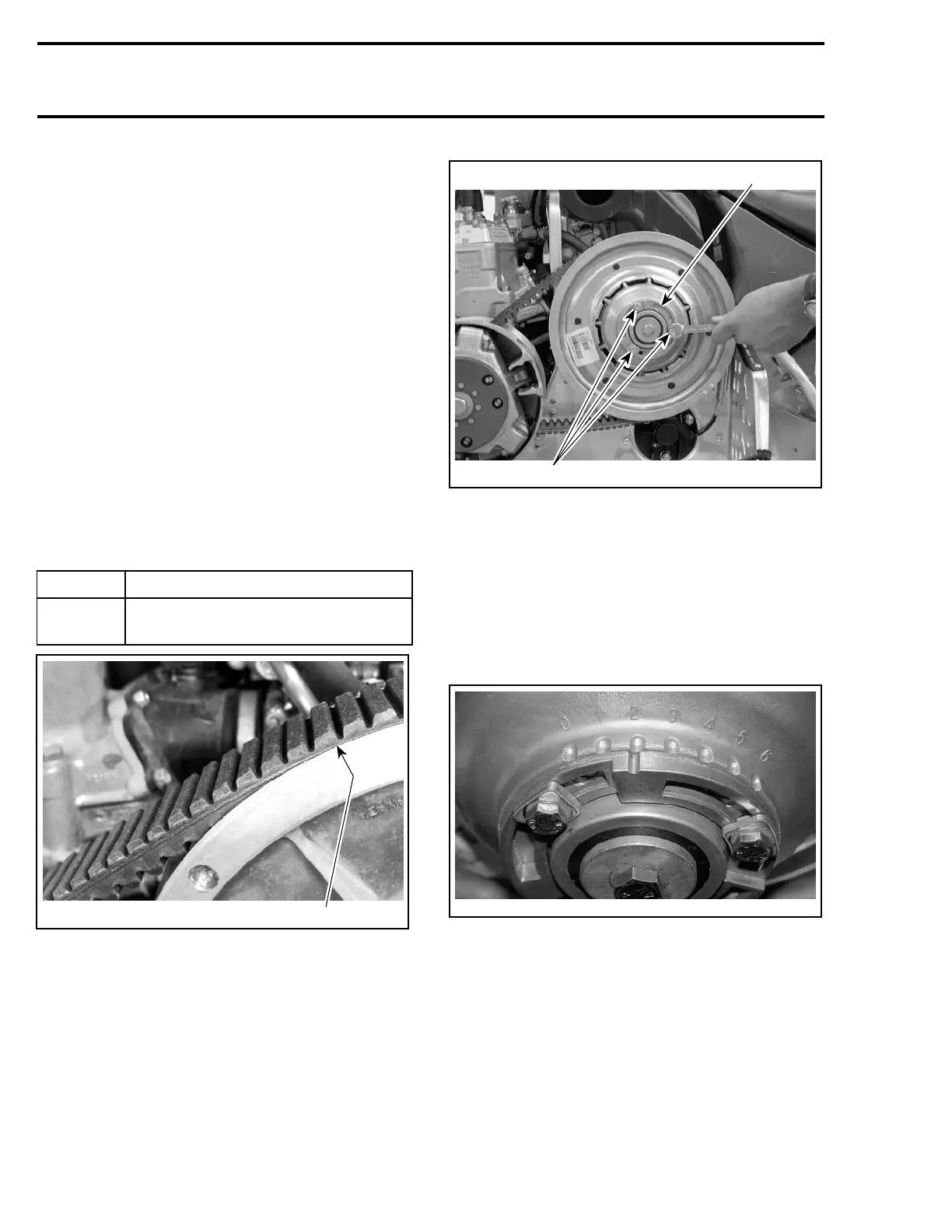

1

A02D1UA

1. Flush

Adjustment

Before adjusting the belt height, ensure that a

good-condition proper belt (refer to the APPLICA-

TION CHART) is installed.

Adjust pulley distance according to specification,

refer to PULLEY DISTANCE AND ALIGNMENT.

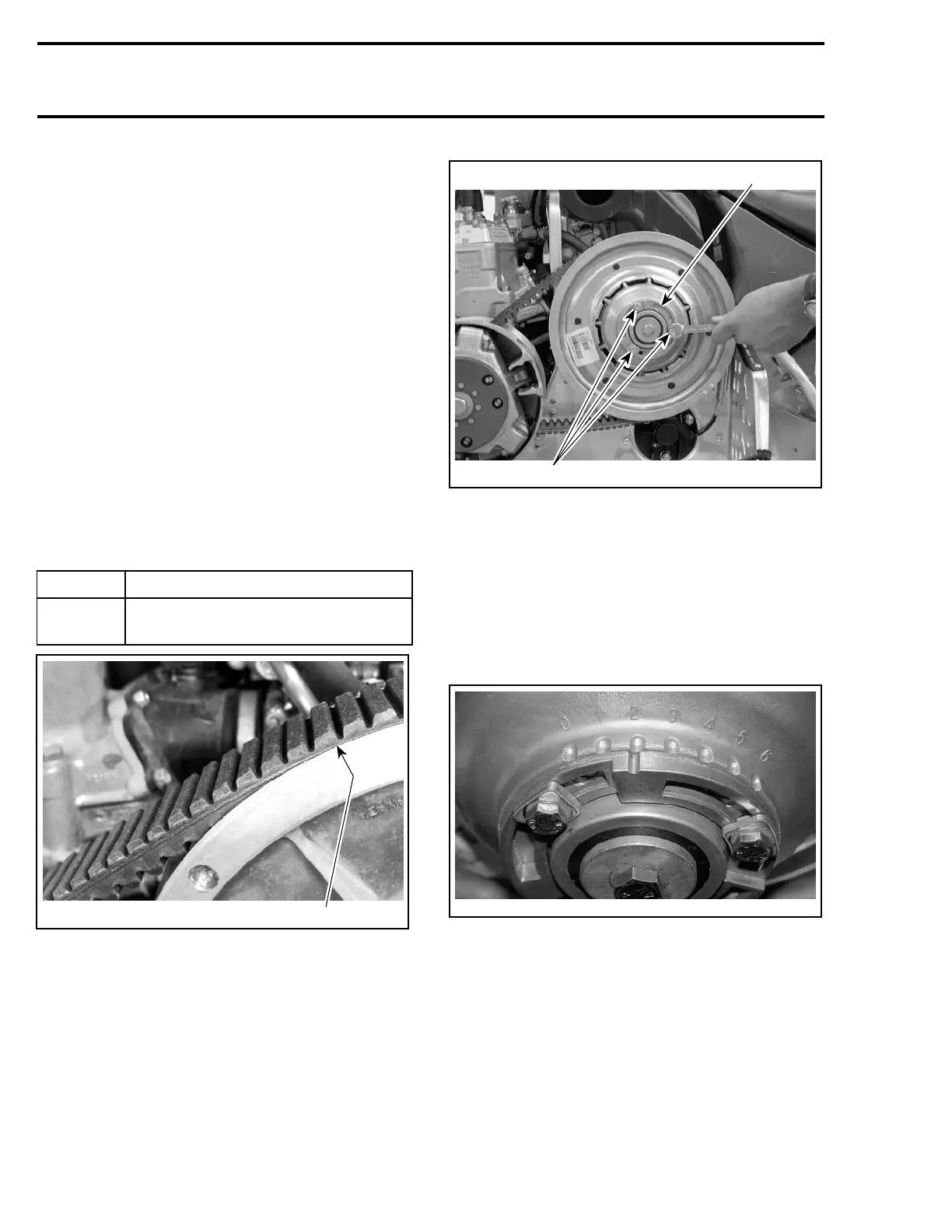

1

2

A33D0DA

TYPICAL

1. Screws

2. Adjustment ring

Loosen screws and turn adjustment ring as fol-

lows:

To lower belt in driven pulley: turn adjustment ring

counterclockwise and tighten the screws.

To raise belt in driven pulley: turn ring clockwise

and tighten the screws.

A33D0EA

DRIVEN PULLEY NOTCHES

Turn the adjustment ring up to one notch, tighten

the screws, then rotate driven pulley to allow drive

belt to settle in pulley. Check height, if required

the adjustment ring can be turned up to 1/4 or 1/2

the notch. Check height, repeat as required.

NOTE: Notches are there on the driven pulley for

reference purpose only and the desired adjust-

ment can be attained at any point.

216 Te m plat e

Loading...

Loading...