Section 06 TRANSMISSION

Subsection 02 (DRIVE PULLEY)

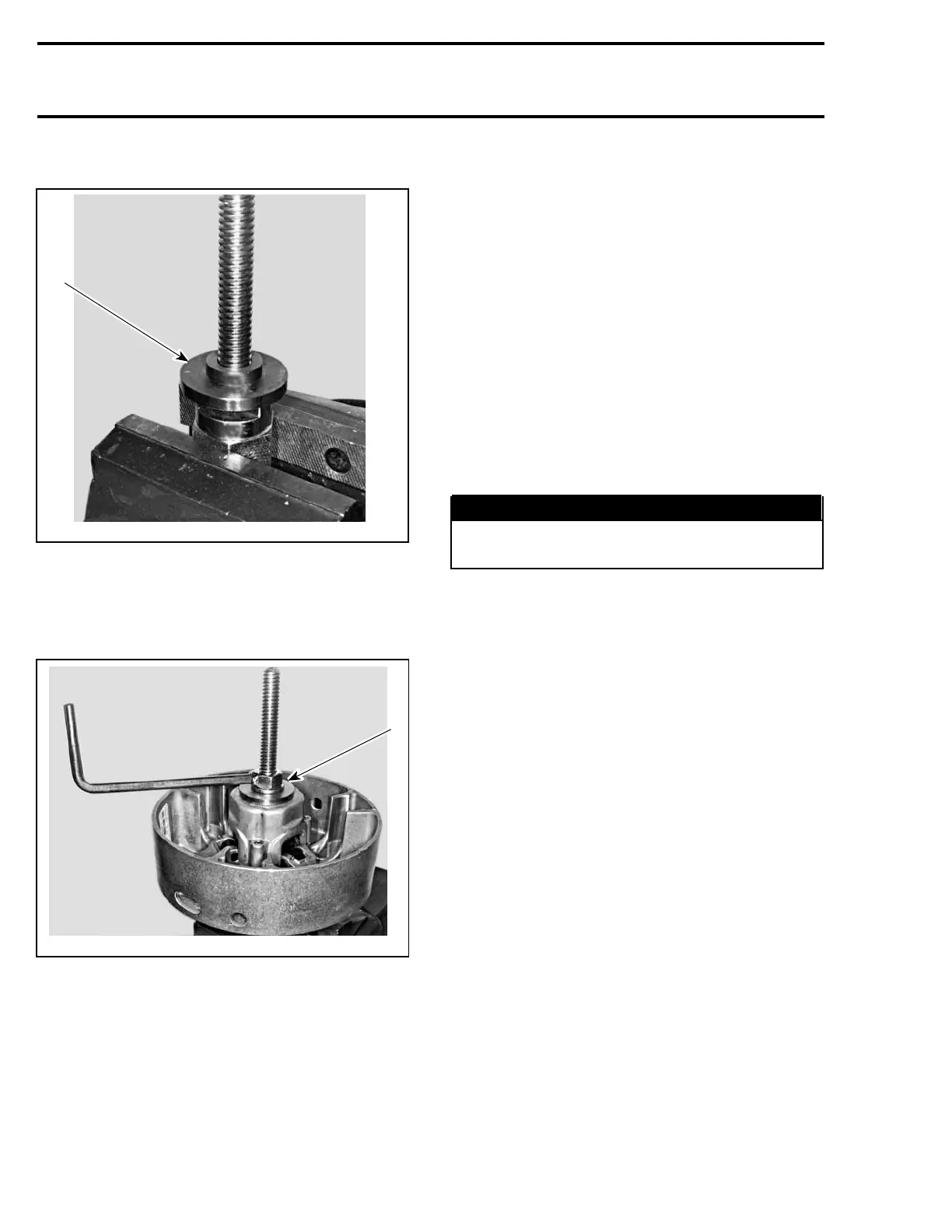

Install support guide.

1

A03D3EA

TYPICAL

1. Support guide

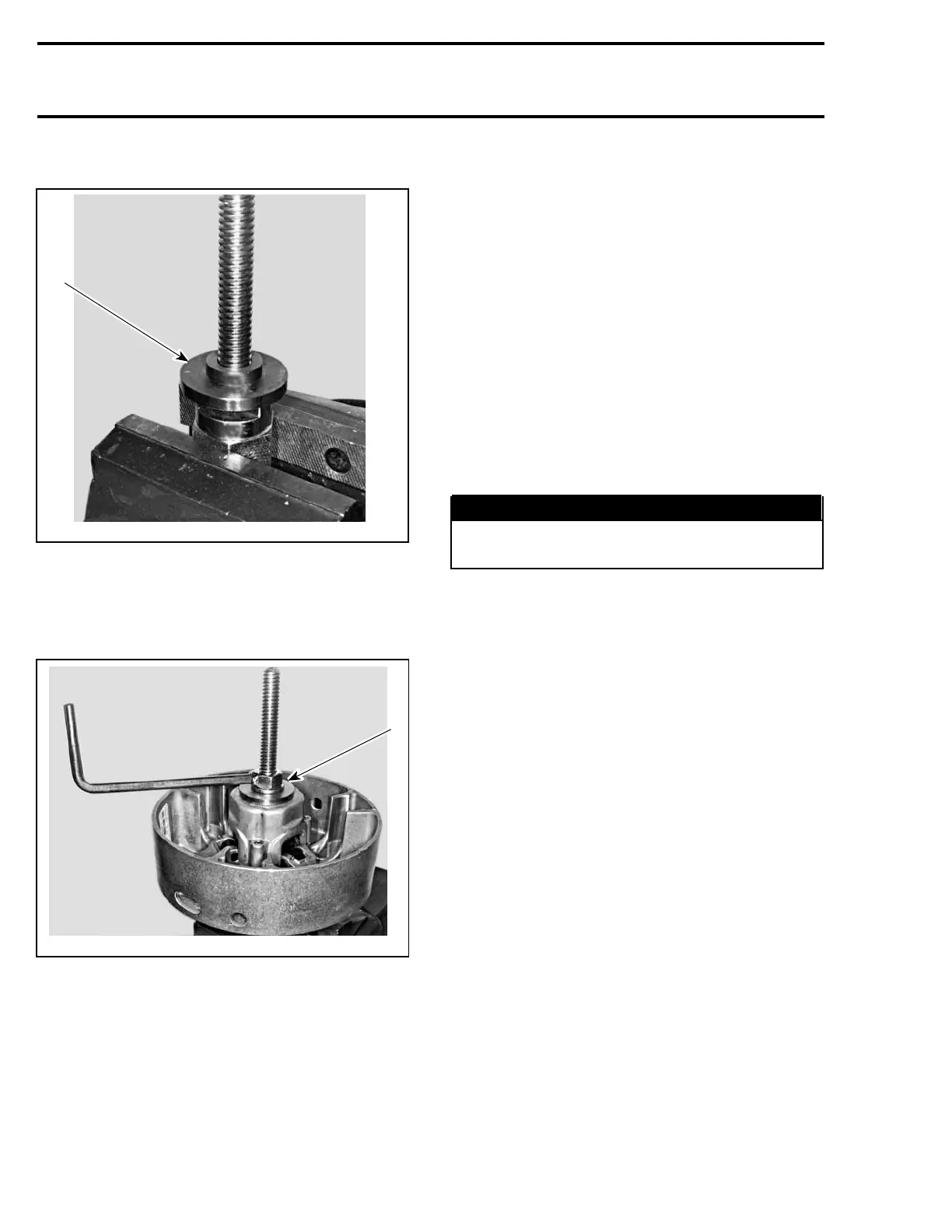

Install sliding half then a second support guide.

These support guides will prevent bushing dam-

ages.

A03D3FA

1

TYPICAL

1. Support guide

Remove 3 Allen screws retaining spring cover

then unscrew compressor.

CLEANING

5,6, Fixed and Sliding Half

Clean pulley faces and shaft with fine steel wool

and clean dry cloth.

5,29, Fixed Half/Crankshaft End and

Governor Cup/Fixed Half Post

Parts must be at room temperature before clean-

ing.

Using a paper towel with Pulley flange cleaner

(P/N 413 711 809), clean crankshaft tapered end,

the taper inside the fixed half, the fixed half post

taper end and the taper inside governor cup.

Before installation of drive pulley, clean also crank-

shaft threads and retaining screw threads.

WARNING

This procedure must be performed in a well-

ventilated area.

CAUTION: Avoid contact between cleaner and

crankshaft seal because damage may occur.

Remove all hardened oil deposits that have baked

on tapered surfaces with coarse or medium steel

wool and/or sand paper no. 600.

CAUTION: Do not use any other type of abra-

sive.

Reclean mounting surfaces with paper towel and

cleaning solvent.

Wipe off the mounting surfaces with a clean, dry

paper towel.

CAUTION: Mounting surfaces must be free of

any oil, cleaner or towel residue.

7,20, Bushing

Only use petrol base cleaner when cleaning bush-

ings.

CAUTION: Do not use acetone to clean bush-

ing.

222 Te m plat e

Loading...

Loading...