Section 06 TRANSMISSION

Subsection 03 (DRIVEN PULLEY)

12, Screws

These screws are machined at there end. With

the adjustment ring set to position 0 (zero), screw

ends are flush with inner side of fixed pulley half

once tightened.

CAUTION: If any of these screws is not flush

with inner side of sliding pulley, bushings will

worn unequally.

Assemble driven pulley components by reversing

the disassembly procedure.

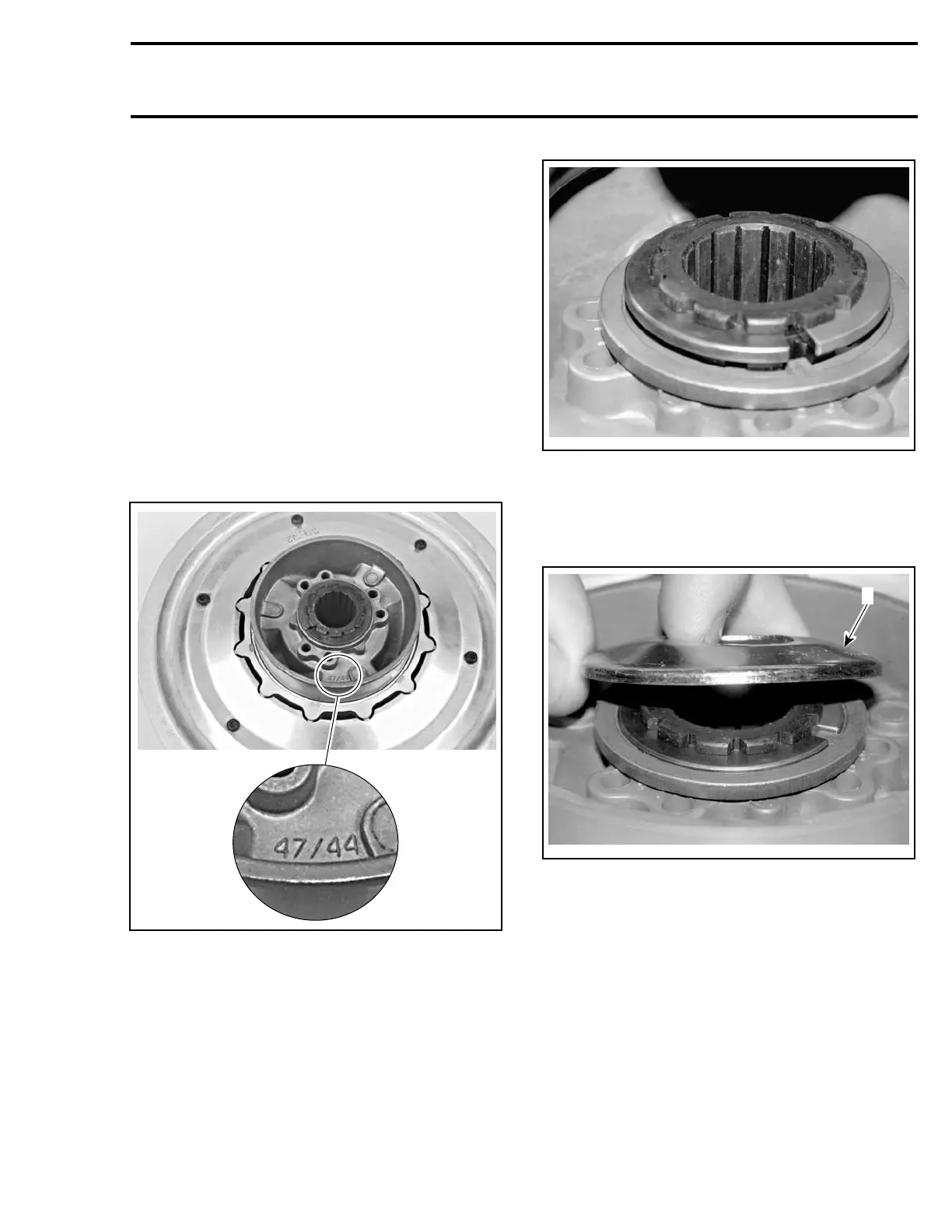

11, Cam

Coat cam interior with anti-seize lubricant.

Make sure to install proper cam. Refer to TECH-

NICAL DATA.

Cam angle is identified on cam.

A30D0XA

NOTE: For high altitude regions, a service bulletin

will give information about calibration according to

altitude.

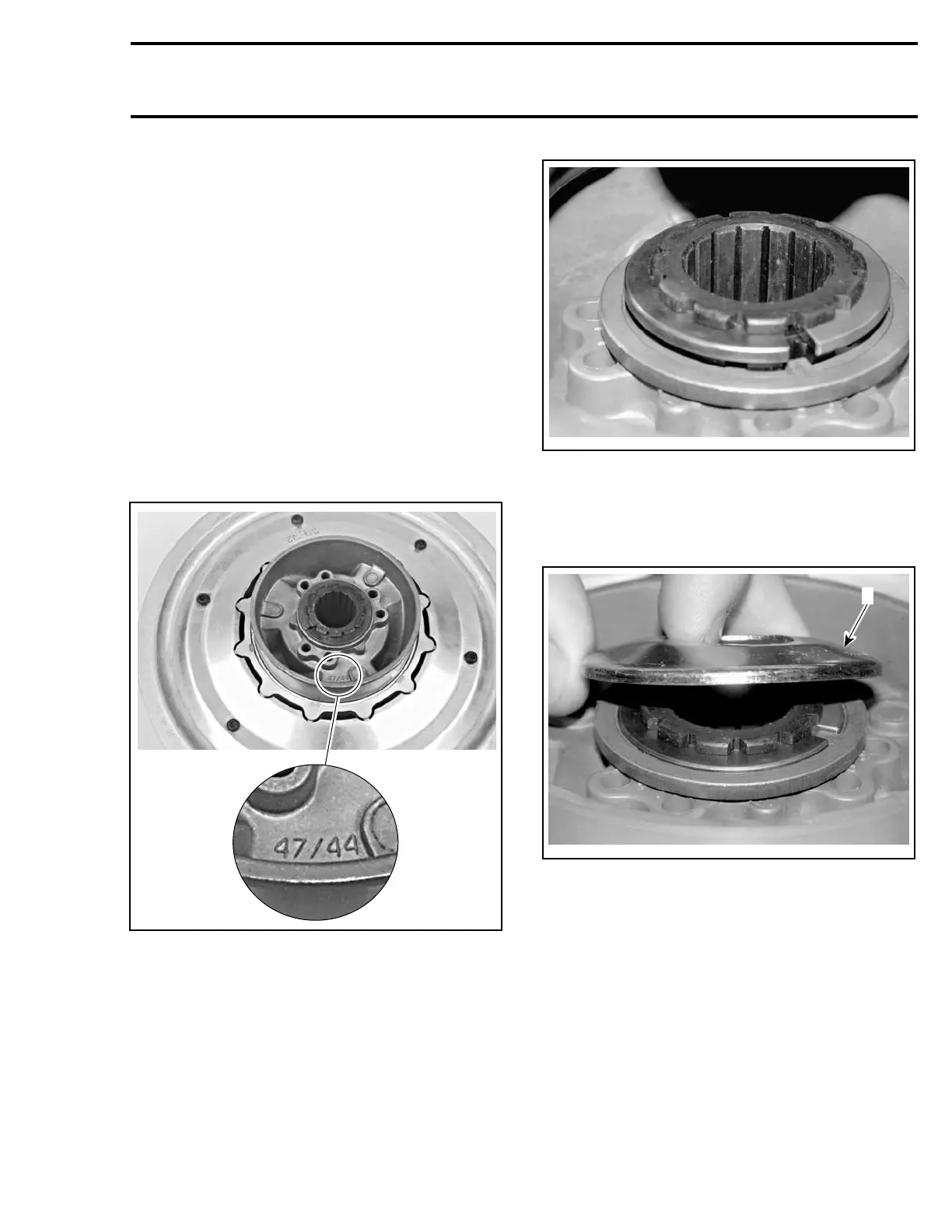

Install spacer no. 7 and half keys no. 6 as per fol-

lowing photo.

A34D0CA

HALF KEYS INSTALLATION

CAUTION: Make sure to install the proper pro-

tector no. 5. The proper protector no. 5 com-

pletely covers the half keys no. 6 and the spacer

no. 7 without touching them.

A34D0DA

1

1. Proper protector

INSTALLATION

5, Countershaft

CAUTION: Always apply anti-seize lubricant

(P/N 293 800 070) on the countershaft before

final pulley installation.

Should installation procedure be required, refer to

BRAKE then look for BRAKE DISC and COUNTER-

SHAFT BEARING ADJUSTMENT.

Reinstall the pulley on the countershaft by revers-

ing the removal procedure.

Te m pla te 229

Loading...

Loading...