Section04ENGINE

Subsection 09 (ENGINE BLOCK)

PISTON RINGS

Removal

Remove piston ass'y as described above.

Remove rings.

Inspection

Ring/Piston Groove Clearance

Using a feeler gauge measure each ring/piston

groove clearance. If the clearance is too large, the

piston and the piston rings should be replaced.

RING/PISTON GROOVE CLEARANCE

mm (in)

NEW MINIMUM

RECTANGULAR

0.025 mm (.001 in)

TAPER-FACE

0.015 mm (.0006 in)

OIL SCRAPER RING 0.020 mm (.0008 in)

NEW MAXIMUM

RECTANGULAR

0.070 mm (.0028 in)

TAPER-FACE 0.060 mm (.0024 in)

OIL SCRAPER RING

0.055 mm (.0021 in)

SERVICE LIMIT

ALL

0.15 mm (.006 in)

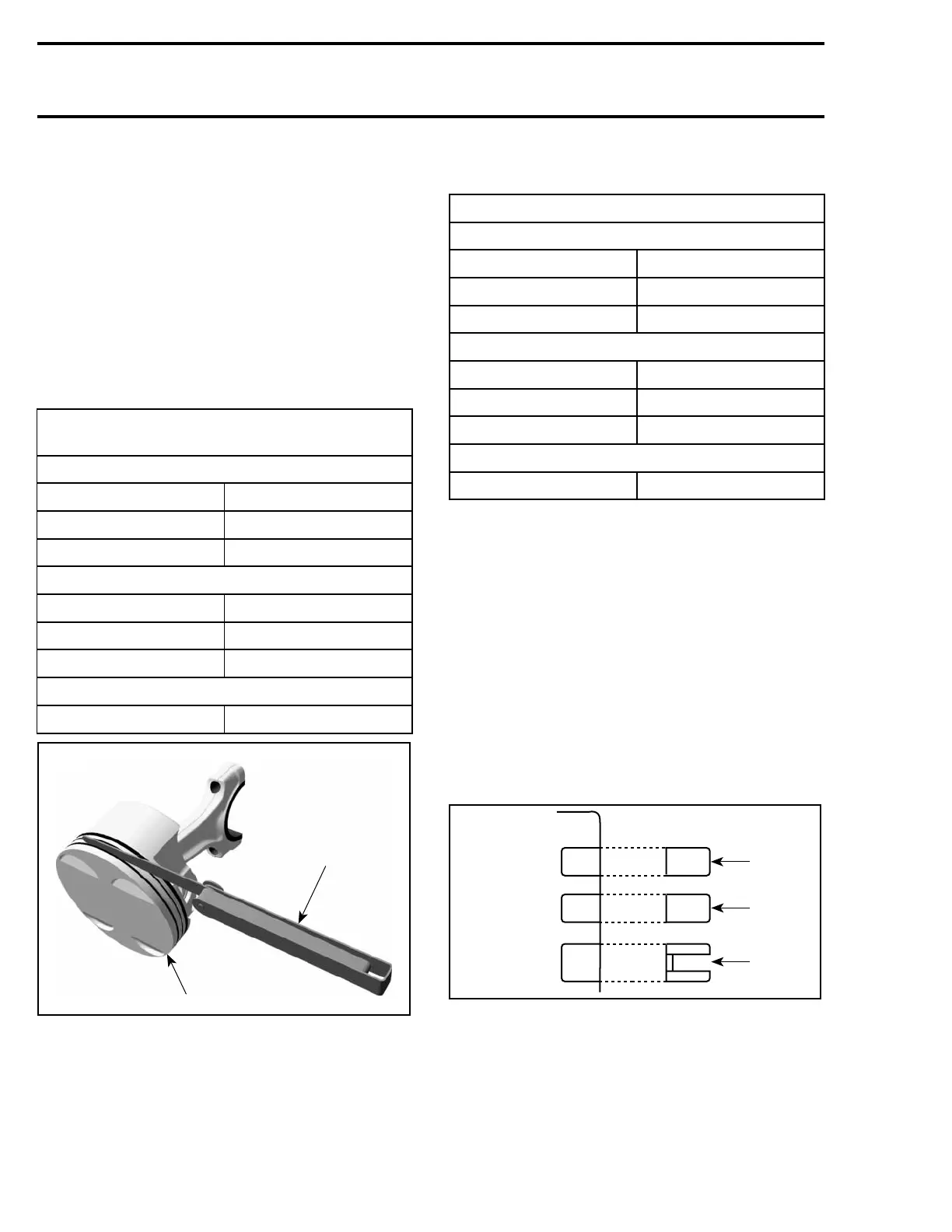

2

R1503motr32A

1

1. Piston

2. Filler gauge

Ring End Gap

RING END GAP mm (in)

NEW MINIMUM

RECTANGULAR 0.15 mm (.006 in)

TAPER-FACE

0.15 mm (.006 in)

OIL SCRAPER RING 0.15 mm (.006 in)

NEW MAXIMUM

RECTANGULAR

0.35 mm (.014 in)

TAPER-FACE 0.35 mm (.014 in)

OIL SCRAPER RING

0.30 mm (.012 in)

SERVICE LIMIT

ALL 1mm(.04in)

Measure position for ring end gap in the area of 8

to16mm(.315to.630in)fromtopofcylinder.

NOTE: In order to correctly position the ring in the

cylinder, use piston as a pusher.

Using a feeler gauge, check ring end gap. Replace

ring if gap exceeds above described specified tol-

erance.

Installation

For installation, reverse the removal procedure.

Pay attention to the following details.

Install the oil scraper ring first, then the taper-face

ring with the word “TO” facing up, then the rect-

angular ring with the word “T” facing up.

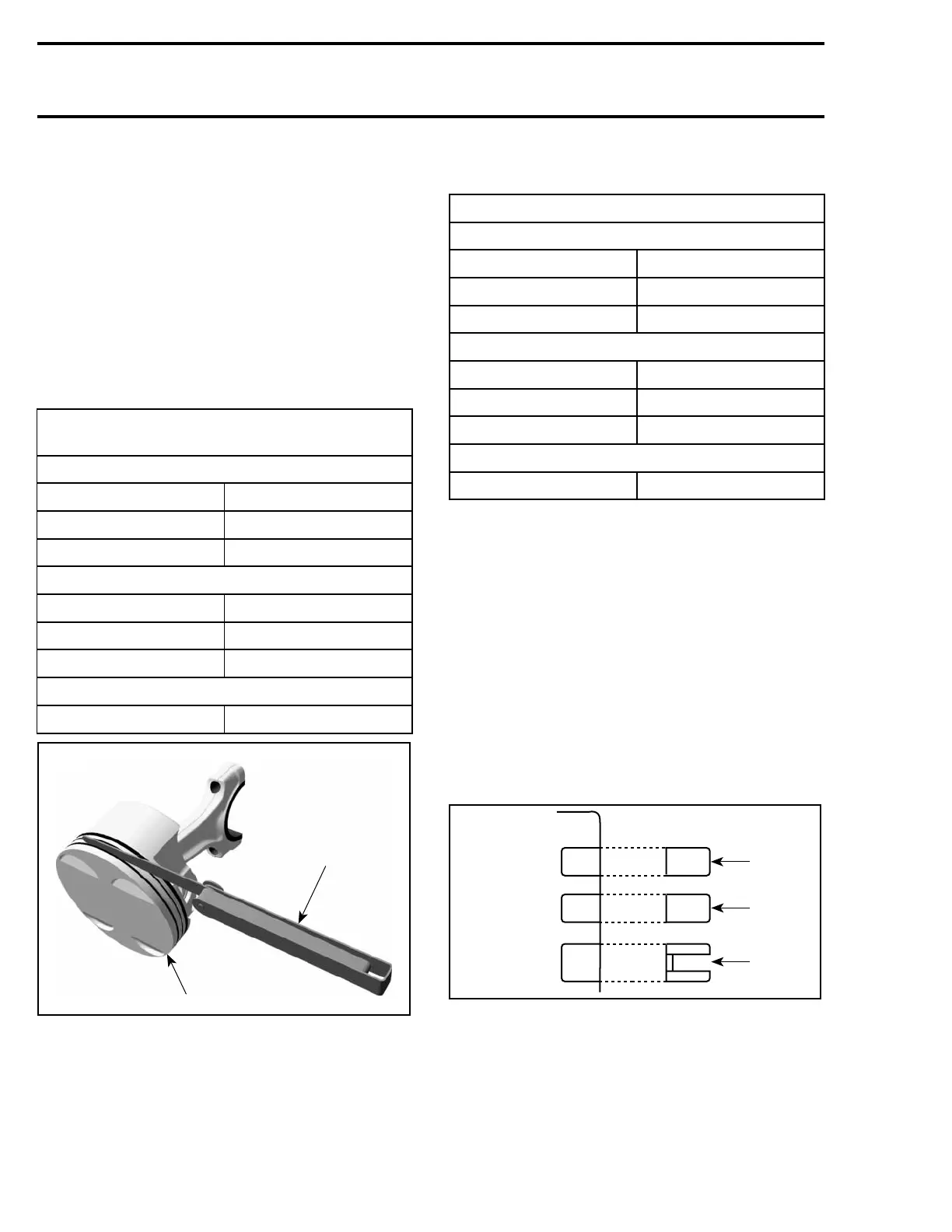

A31C2NA

1

2

3

1. Rectangular ring

2. Taper-face ring

3. Oil scraper ring

CAUTION: Ensure that top and second rings are

not interchanged

164 Te m plat e

Loading...

Loading...