Section 06 TRANSMISSION

Subsection 06 (GEARBOX AND FINAL DRIVE BELT)

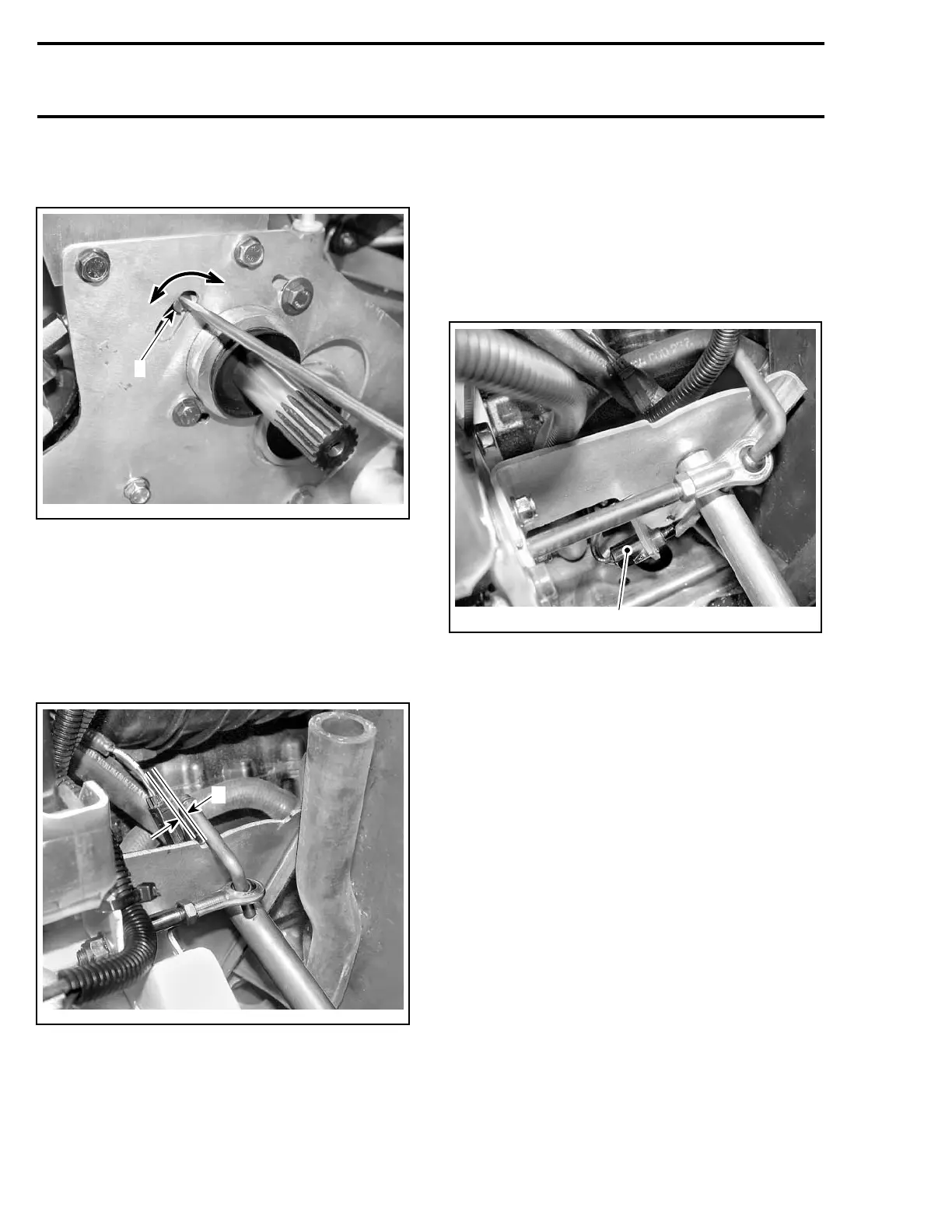

To adjust, loosen lock nut no. 8 and turn fork axle

accordingly.

A34D0MA

1

DRIVEN PULLEY REMOVED

1. Fork axle end

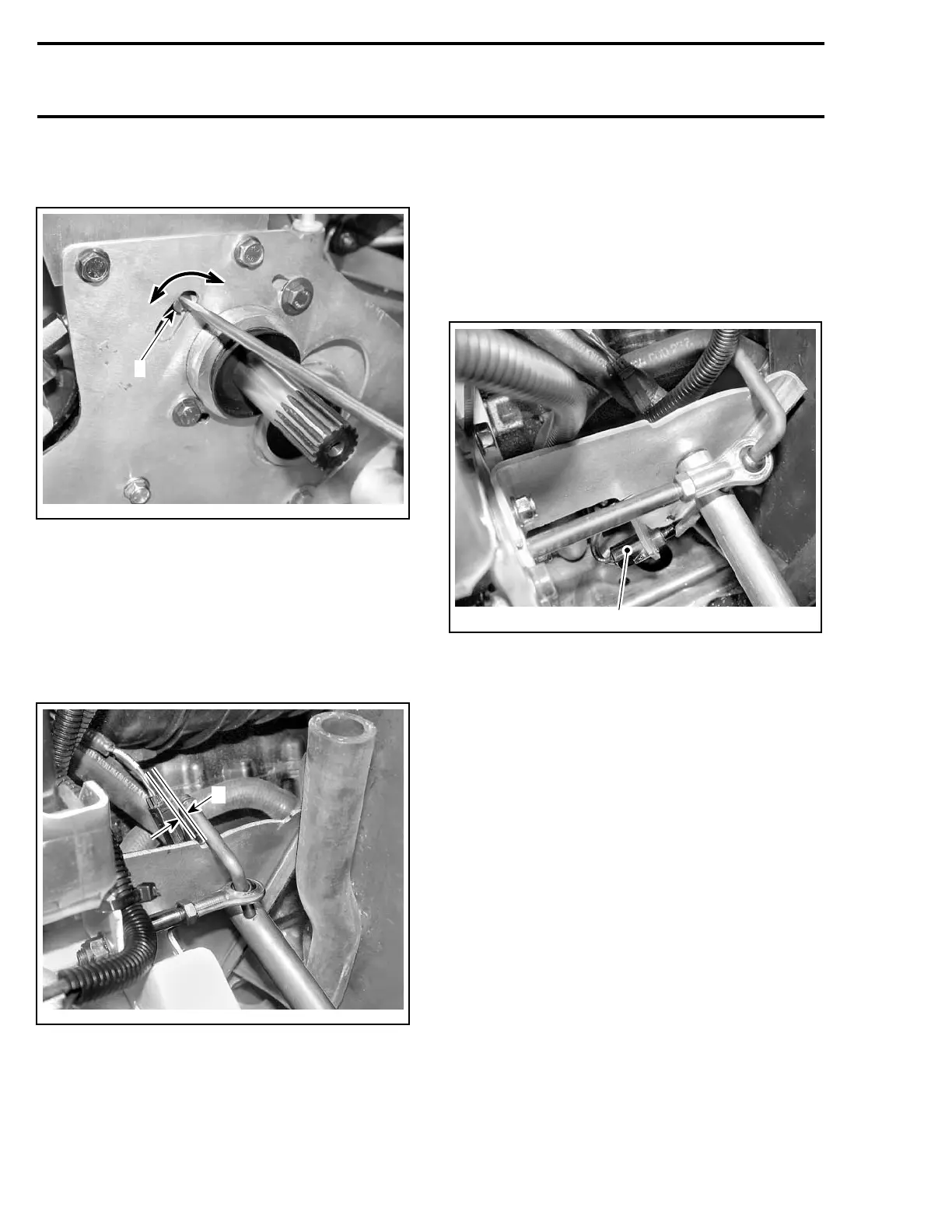

Before tightening lock nut no. 8, position ball joint

no. 10 90° to pivot no. 7 to allow proper ball joint

free rotation.

Shift in forward position.

Check if pivot no. 7 is at least 0.5 mm (.020 in)

from stopper.

A34D0NA

A

FORWARD POSITION

A. 0.5 mm (.020 in)

To adjust, proceed as described above.

Check reverse switch adjustment as described

above.

REVERSE SWITCH ADJUSTMENT

Short to ground the ORANGE/WHITE wire of

VCM. Refer to TESTING PROCEDURE.

Shift in reverse.

Reverse alarm must sound. If not, unplug reverse

switch to avoid twisting wires, loosen lock nut and

screw switch in.

A34D0LB

1

1. Reverse switch

Reconnect and check for sound. Repeat adjust-

ment as required.

Reconnect switch and tighten lock nut. Recon-

nect ORANGE/WHITE wire.

REMOVAL

Remove the drive belt and the driven pulley.

Remove the battery. Refer to BATTERY.

Remove the battery rack no. 12.

Drain gearbox oil as explained in OIL CHANGE.

Remove final drive belt from top drive sprocket as

explainedinFINALDRIVEBELT.Removethedrive

sprocket from output shaft of gearbox.

Unfasten fork axle from ball joint no. 10.

Remove transmission support no. 11.

Unbolt gearbox from chassis and remove it.

DISASSEMBLY

Unbolt the gearbox cover no. 1.

244 Te m plat e

Loading...

Loading...