Section07ELECTRICALSYSTEM

Subsection 01 (ALTERNATOR)

REMOVAL

Disconnect BLACK negative cable from battery.

WARNING

Battery BLACK negative cable must always be

disconnected first and connected last.

Remove air silencer, foam and belt guard.

Disconnect RED cable from alternator. Discon-

nect electric connector from alternator.

Loosen alternator belt tension. To do so, loosen

alternator mounting bolt no. 5 and retaining bolt

no. 6, then lock nuts no. 3. Turn adjustment rod

no. 2 accordingly.

Remove alternator belt from alternator pulley.

Unfasten adjustment rod no. 2 from alternator,

then remove mounting bolt no. 5. Remove alter-

nator.

NOTE: If the engine pulley or the alternator belt

needs to be replaced, refer to PTO HOUSING.

INSPECTION

NOTE: The alternator does not require any main-

tenance and must not be opened for repair work.

Inspect the housing and ball bearings for damage

or wear. In case of damage, the alternator must

be replaced. The alternator can only be replaced

as a complete assembly.

INSTALLATION

The installation is the reverse of removal proce-

dure. Pay attention to the following details.

Make sure to install a washer no. 7 on each side

of alternator mounting emboss and alternator sup-

port no. 4.

Proceed with alternator belt tension adjustment.

BELT TENSION ADJUSTMENT

Make sure alternator mounting bolt no. 5,retain-

ing bolt no. 6 and lock nuts no. 3 are loose.

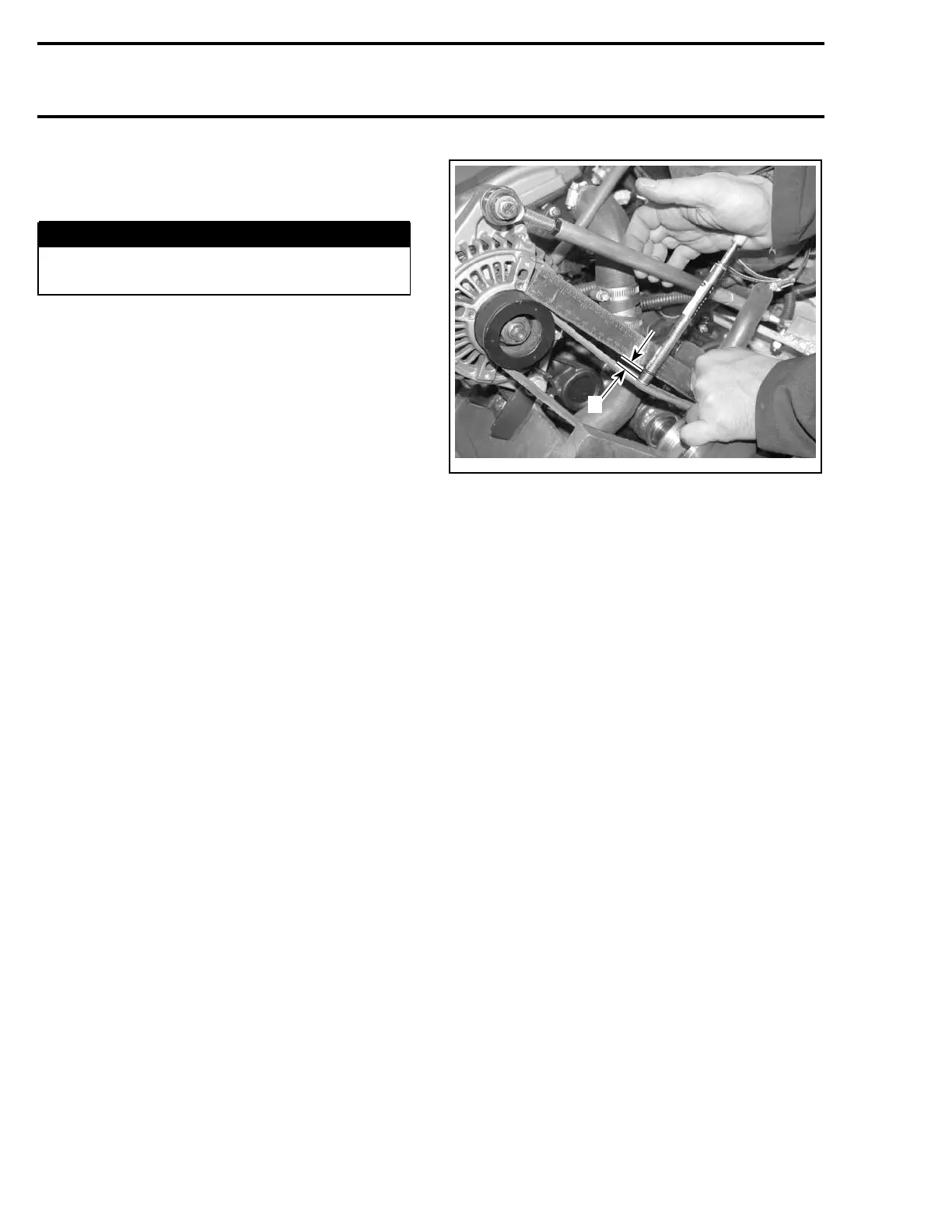

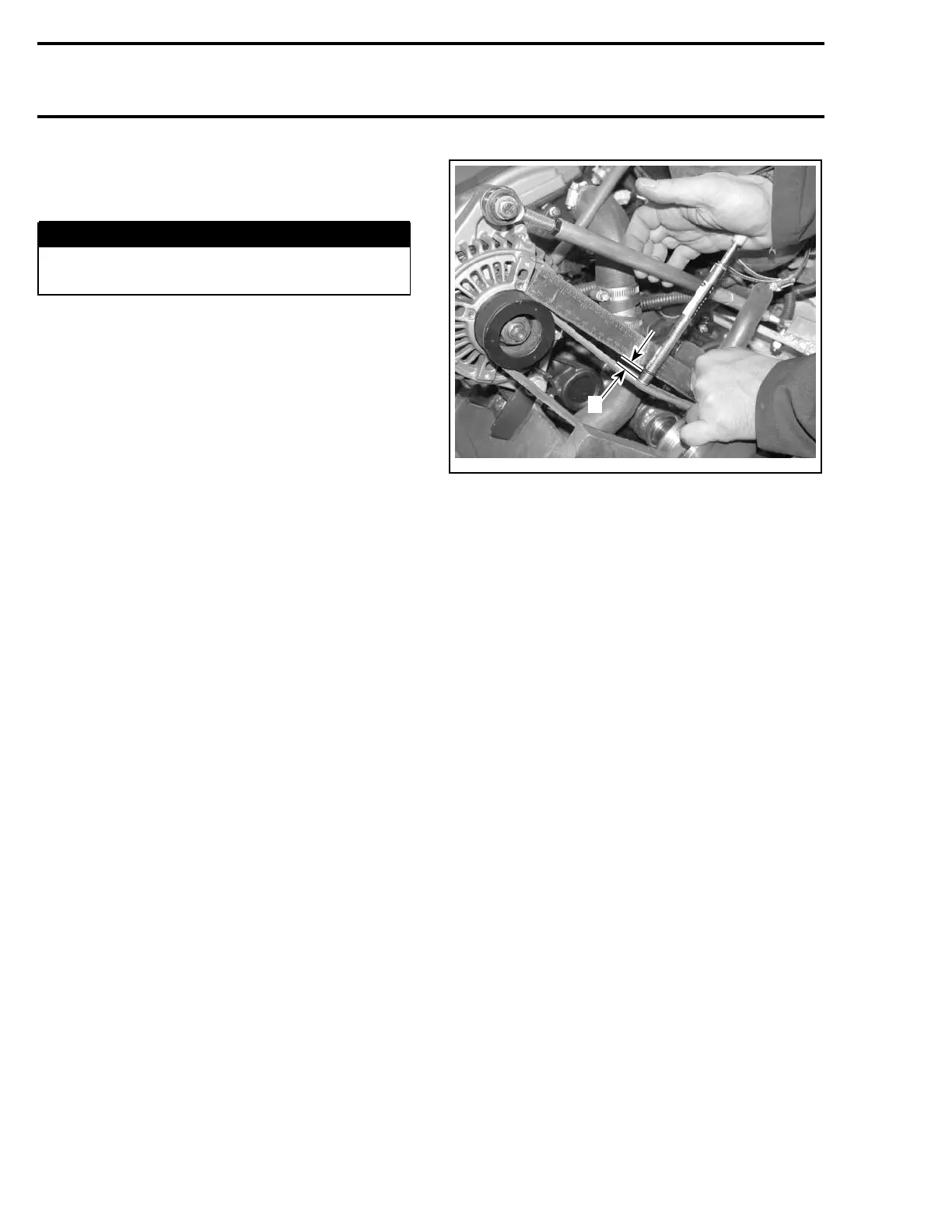

Measure belt deflection when applying a down-

wardforceof2.27kg(5lb)onthebeltatmid

point between pulleys. Deflection must be 4 mm

(.157 in).

A34E0HA

A

A. Deflection

Turn adjustment rod no. 2 accordingly. Retighten

lock nuts no. 3, alternator mounting bolt no. 5

and retaining bolt no. 6, then recheck deflection.

Readjust if required.

250 Te m plat e

Loading...

Loading...