Section 05 ENGINE MANAGEMENT

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

If wiring harness is defective, repair the connector

or replace the wiring harness between ECM ECU

connector and the ignition coil.

If wiring harness is good, test resistance of pri-

mary and secondary winding of ignition coil.

Resistance Test

CAUTION: Do not remove the ignition coil be-

fore disconnecting the connector, or the wires

will be damaged. Do not pry up ignition coil

with a screwdriver to avoid damage.

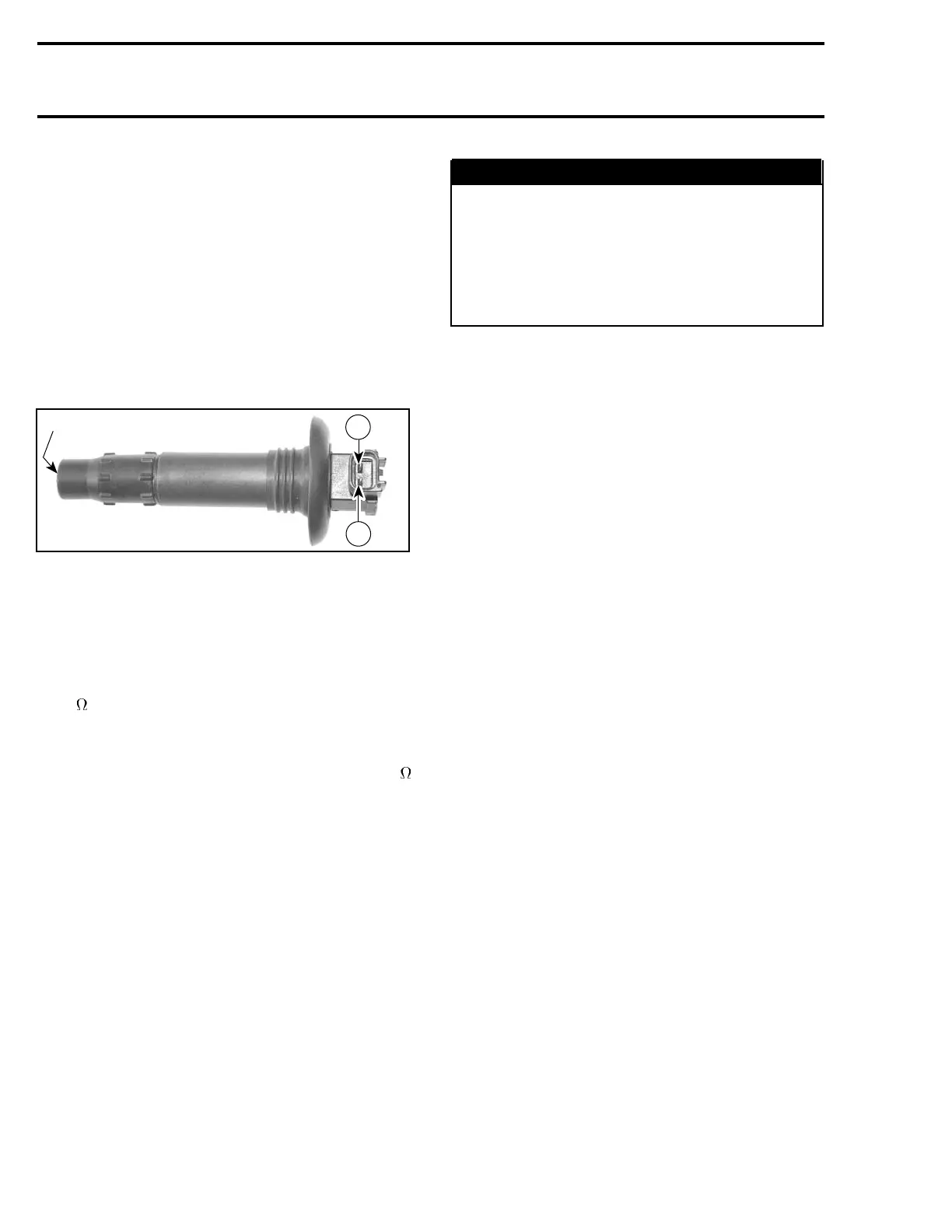

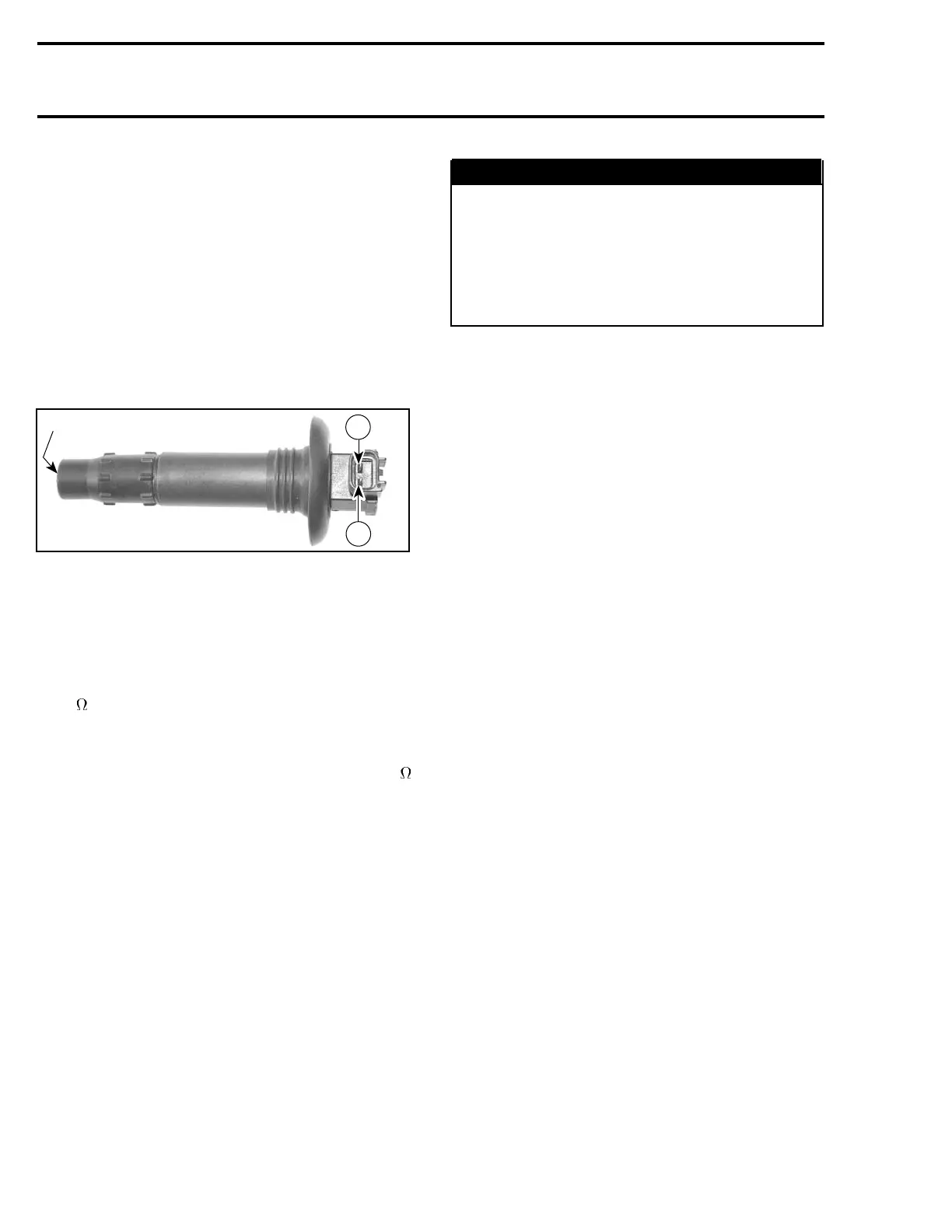

Remove ignition coil from spark plug.

1

R1503motr197A

2

1

1. Spark plug terminal

Using a multimeter, check the resistance in both

primary and secondary windings.

For primary winding check the resistance be-

tween terminals 1 and 2 of the ignition coil.

The resistance should be between 0.85 and

1.15

at 20°C(68°F).

For secondary winding check the resistance be-

tween terminal 1 and spark plug terminal.

The resistance should be between 9.5 and 13.5 k

at 20°C(68°F).

If the resistance of one of both windings is not

good, replace the defective ignition coil.

If the windings test good, try a new engine ECM

ECU.

NOTE: Prior to inserting the ignition coil to its lo-

cation, apply some silicone lubricant (P/N 293 600

041) around the seal area that touches the spark

plug hole. After installation, ensure the seal seats

properly with engine top surface.

WARNING

Always reconnect ignition coil cables at the

same spark plugs where they come from.

Otherwise, severe backfire may occur with

possible damage to exhaust system com-

ponents. The genuine wiring harness is

designed to prevent a cable mixing by using

different cable lengths.

TDC SETTING (TOP DEAD

CENTER)

The ECM is able to determine the exact position

of camshaft and crankshaft. That means that no

TDC setting has to be performed. It is used for

both injection and ignition timings.

ENGINE START SWITCH

VERIFICATION

If the vehicle fails to wake-up or start while turning

ON the ignition switch, check battery voltage and

fuses.

NOTE: Make sure the engine cut-out switch is not

in operation.

DESS SWITCH VERIFICATION

If 2 short beeps are not heard whenengine is

started, refer to DIAGNOSTIC PROCEDURES.

The following continuity tests can also be per-

formed using an ohmmeter.

Disconnect DESS post wires.

Tether Cord Cap Removed

Connect test probes to DESS post BLACK/WHITE

and BLACK wires. Measure resistance, there

should be NO continuity (open circuit).

Connect one test probe to the WHITE/GRAY wire

and the other test probe to the switch top termi-

nal. Measure resistance, it must be close to 0

ohm.

Connect one test probe to the BLACK/WHITE wire

and the other test probe to the DESS post ring.

Measure resistance, it must be close to 0 ohm.

206 Te m plat e

Loading...

Loading...