Section 05 ENGINE MANAGEMENT

Subsection 01 (OVERVIEW)

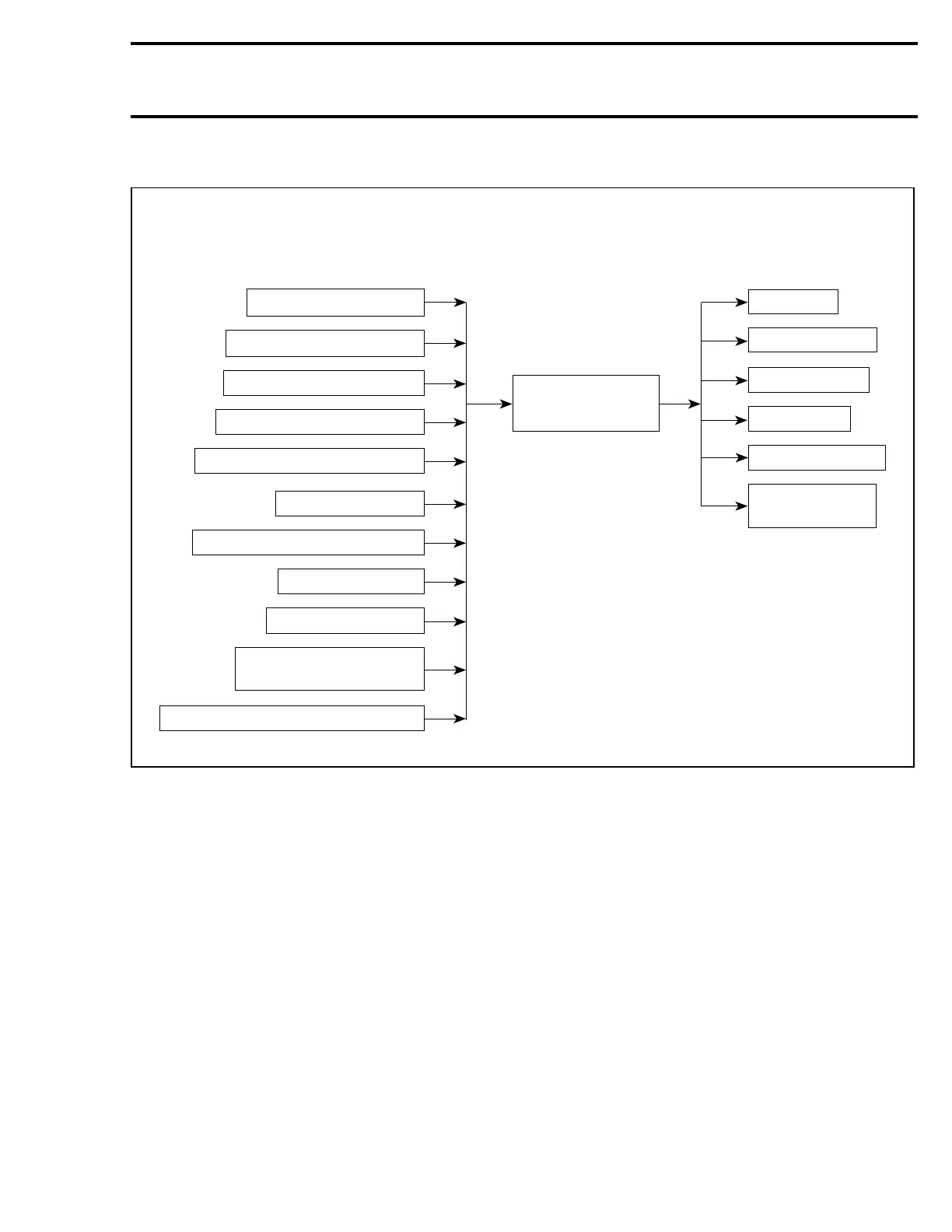

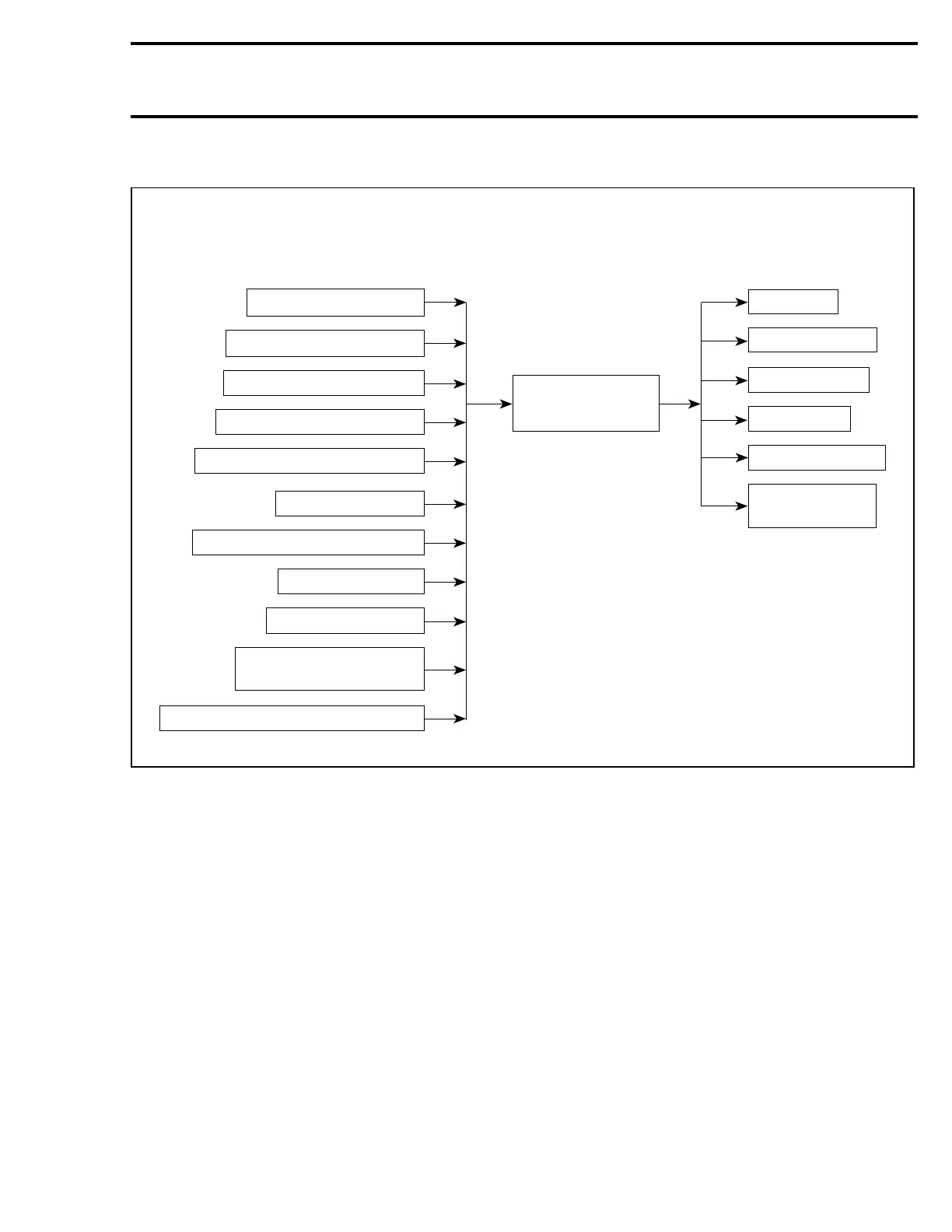

EMS — ENGINE MANAGEMENT FUNCTIONS

A34C1GS

1503 4-TEC CONTROL SYSTEM

INPUTS OUTPUTS

Idle bypass valve

Fuel injector

Ignition coil (3)

Starter solenoid

Fuel pump

Communication

port to VCM

Tip-over protection system (TOPS)

Digitally Encoded

Security System (DESS)

Battery voltage (BV)

Knock sensor (KS)

Throttle position (TPS)

Crankshaft position (CPS)

Coolant temperature (CTS)

Manifold air pressure (MAPS)

Oil pressure (OPS)

Oil tank pressure (OTPS)

Camshaft position (CAPS)

ENGINE CONTROL

MODULE

(ECM)

This engine management system controls both

the fuel injection and the ignition timing.

As shown in the CONTROL SYSTEM illustration,

the ECM ECU is the central point of the fuel injec-

tion system. It reads the inputs, makes computa-

tions, uses pre-determined parameters and sends

the proper signals to the outputs for proper engine

management.

The ECM ECU also stores the fault codes and gen-

eral information such as: operating conditions, ve-

hicle hours, serial numbers, customer and mainte-

nance information.

Electronic Fuel Injection

The ECM ECU reads the signals from different

sensors which indicate engine operating condi-

tions at milli-second intervals.

Signals from sensors are used by the ECM ECU

to determine the injection parameters (fuel maps)

required for optimum air-fuel ratio.

The CPS, the MATS, the MAPS and the TPS are

the primary sensors used to control the injection

and ignition timing. Other sensors (like tempera-

ture sensors, etc.) are used for secondary input.

NOTE: The OPS and OTPS sensors do not provide

control inputs to the ECM ECU. Their sole purpose

is to protect the engine components by emitting a

warning signal and/or a fault code in the event of

overheating or low oil pressure.

Ignition System

The ignition system is a digital inductive type. The

ECM ECU controls the ignition system parame-

ters, such as spark timing, duration and firing in

order to achieve the proper engine requirements.

Te m pla te 173

Loading...

Loading...