Section04ENGINE

Subsection 07 (LUBRICATION SYSTEM)

Run engine for 10 seconds at 4000 RPM and shut

it off at this RPM. This will move oil from PTO

housing to oil tank to allow maximum oil draining.

Remove oil filler cap and dipstick.

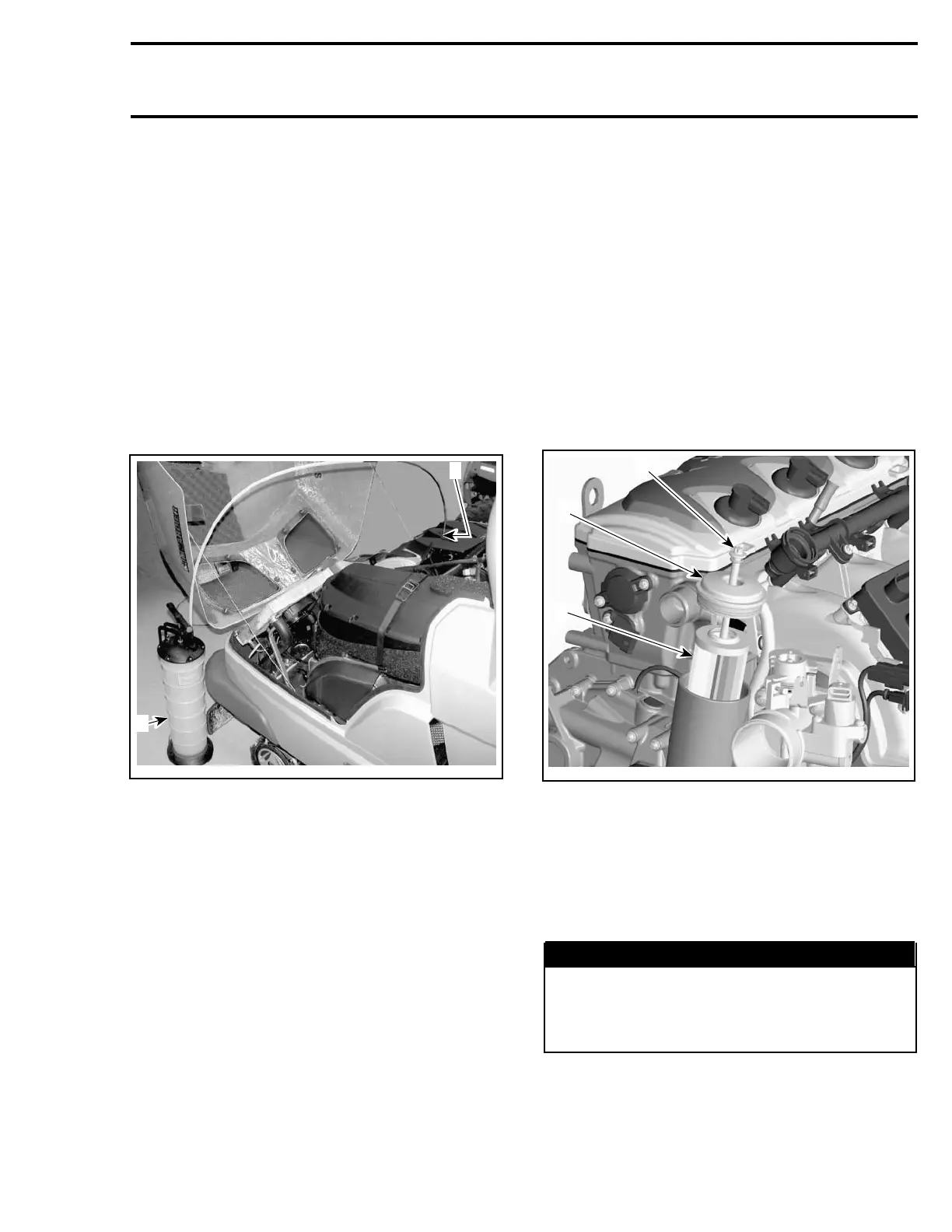

Using the Oil VAC (P/N 529 035 880), siphon oil

through dipstick hole.

CAUTION: Never crank or start engine when

siphon tube is in dipstick hole. Never start en-

gine when there is no oil in engine.

NOTE: Since the siphon tube must be inserted

at the proper depth to siphon the oil, it is sug-

gested to put some electrical tape on siphon tube

at 475 mm (18.7 in) from its end. Then, insert

siphon tube until you reach the tape.

A34C0ZA

2

1

1. Oil VAC

2. Siphon tube in dipstick hole

Pull siphon tube out of dipstick hole. Make sure

that drive belt is removed. Crank engine (do not

start) while in engine drown mode (fully depress

throttle lever and HOLD, then crank engine).

Crank engine for 10 seconds. Siphon oil again.

Repeat the crank-siphon cycle 2 - 3 times.

Inspection

Oil condition gives information about the engine

condition. See TROUBLESHOOTING section.

Installation

Reinstall removed parts and fill in the new engine

oil.

OIL TYPE AND SYSTEM

CAPACITY

Refer to TECHNICAL DATA. For refilling proce-

dure, refer to OIL LEVEL VERIFICATION above.

OIL FILTER

Removal

Remove:

– engine oil (refer to OIL CHANGE)

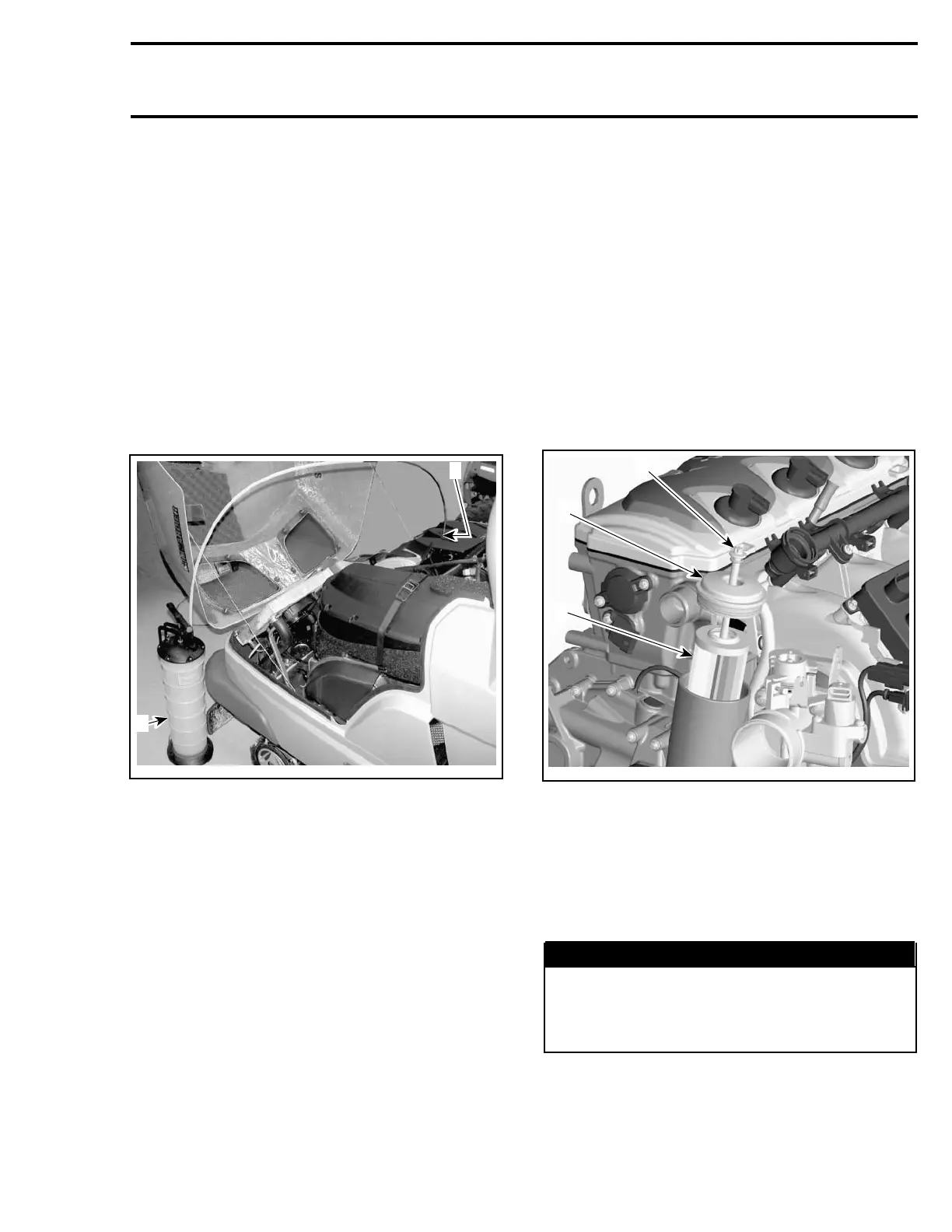

– oil filter screw no. 1

– oil filter cover no. 2

– oil filter no. 3.

R1503motr281A

1

2

3

TYPICAL

1. Oil filter screw

2. Oil filter cover

3. Oil filter

Place rags around filter housing to prevent

spillage. If spillage occurs, clean immediately

with the pulley flange cleaner (P/N 413 711 809)

to prevent stains.

WARNING

Wear safety glasses and work in a well venti-

lated area when working with strong chem-

ical products. Also wear suitable non-ab-

sorbent gloves to protect your hands.

Te m pla te 111

Loading...

Loading...