Section04ENGINE

Subsection 06 (COOLING SYSTEM)

NOTE: Follow hydrometer manufacturer instruc-

tions for proper use.

The reading should be - 37°C(-37°F) or lower.

Add demineralized water or antifreeze accord-

ingly. Refill to the proper level.

CAUTION: Pure antifreeze will freeze at a

higher temperature than the optimal water/an-

tifreeze mix.

COOLANT PUMP HOUSING

R1503motr317B

1

1. Coolant pump housing

Removal

Drain cooling system (see above) and engine oil

(refer to LUBRICATION SYSTEM).

Remove from housing:

– oil cooler outlet hose no. 7

– coolant hose no. 8

– screws no. 12 and no. 13 retaining coolant

pump housing no. 14

– coolant pump housing no. 14.

Inspection

Check if gasket no. 15 is brittle, hard or damaged

and replace as necessary.

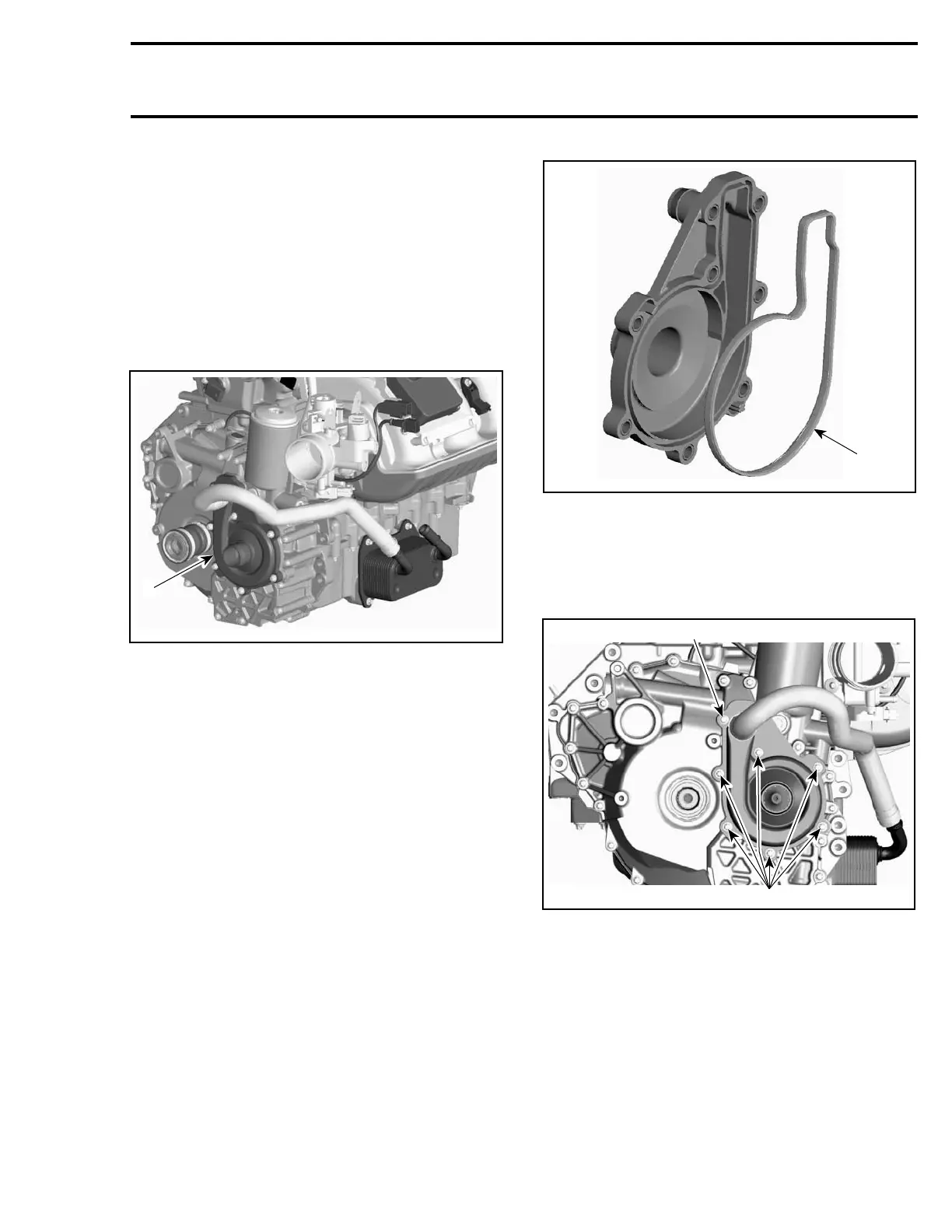

R1503motr316A

1

1. Pump housing gasket

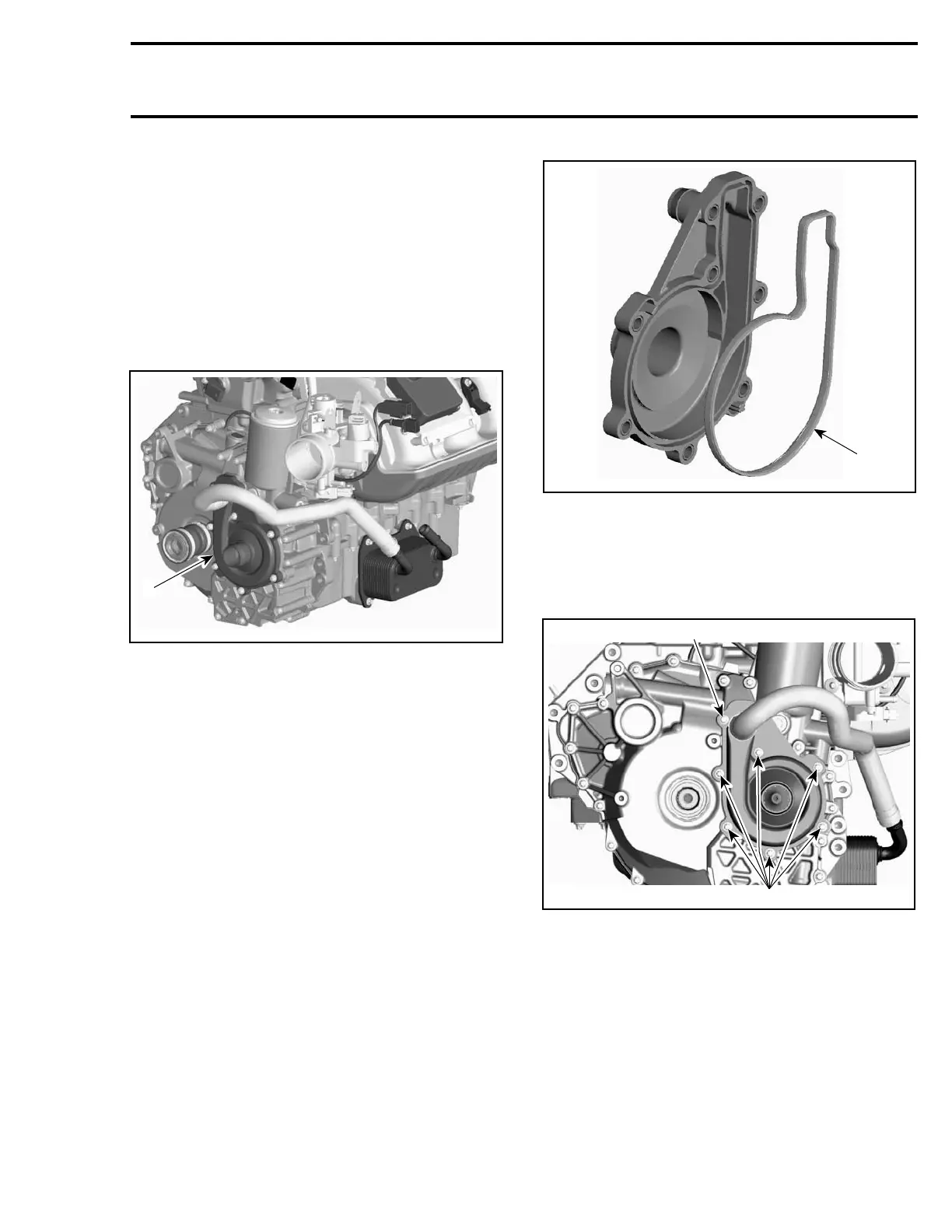

Installation

The installation is the opposite of the removal pro-

cedure. Install screws as per the following illus-

tration.

R1503motr315A

1

2

1. Screws M6 x 25

2. Screws M6 x 105

CAUTION: To prevent leaking, take care that the

gaskets are exactly in groove when you rein-

stall the coolant pump housing.

Apply Loctite 243 on screw threads and torque to

10 N•m(89lbf•in).

Tightening sequence for screws on coolant pump

housing is as per following illustration.

Te m pla te 101

Loading...

Loading...