Section 05 ENGINE MANAGEMENT

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

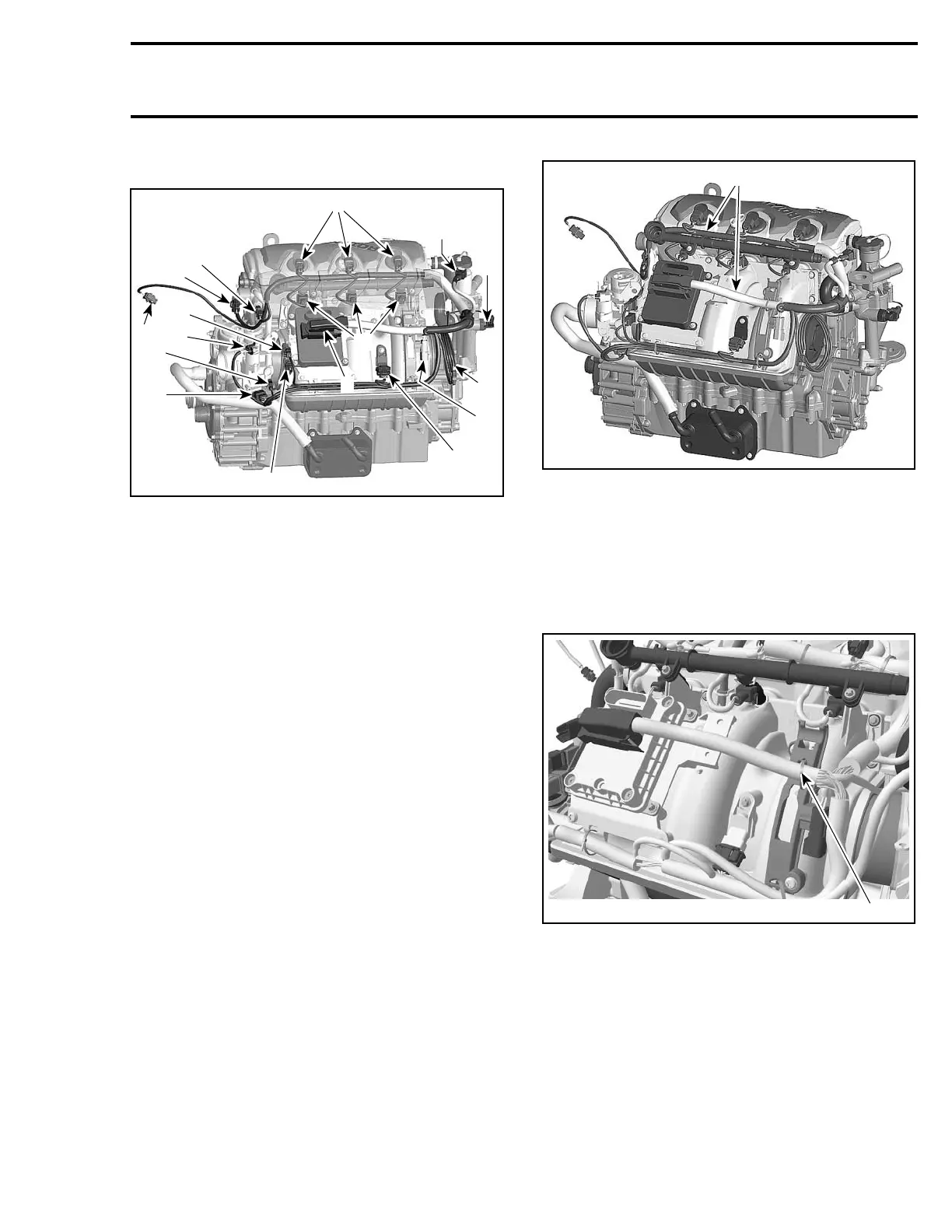

ENGINE WIRING HARNESS

R1503motr322A

1

2

11

14

15

9

7

6

3

4

8

13

10

12

16

5

4-TEC ENGINES

1. Ignition coils

2. BBV

3. OPS (hidden behind throttle body)

4. Idle bypass valve

5. Engine connector

6. Potentiometer

7. KS

8. Crank sensor

9. Connector housing

10. Temperature sensor

11.Injectors

12. WTS

13.CAPS

14. WTS

15. MAPS

16. OTPS

Resistance Test

Check continuity of the circuits according to the

wiring diagram in the WIRING DIAGRAMS section

of this manual.

If wiring harness is good, check the respective

sensor/actuator as described in this section.

Otherwise, repair the connectors, replace the

wiring harness or the ECM ECU/VCM as diag-

nosed.

Removal

Remove fuel rail cover.

Disconnect the wiring harness from all sensors/ac-

tuators.

Disconnect the ECM ECU connector from the

ECM ECU.

Cut all tie raps which are holding the wiring har-

ness in position.

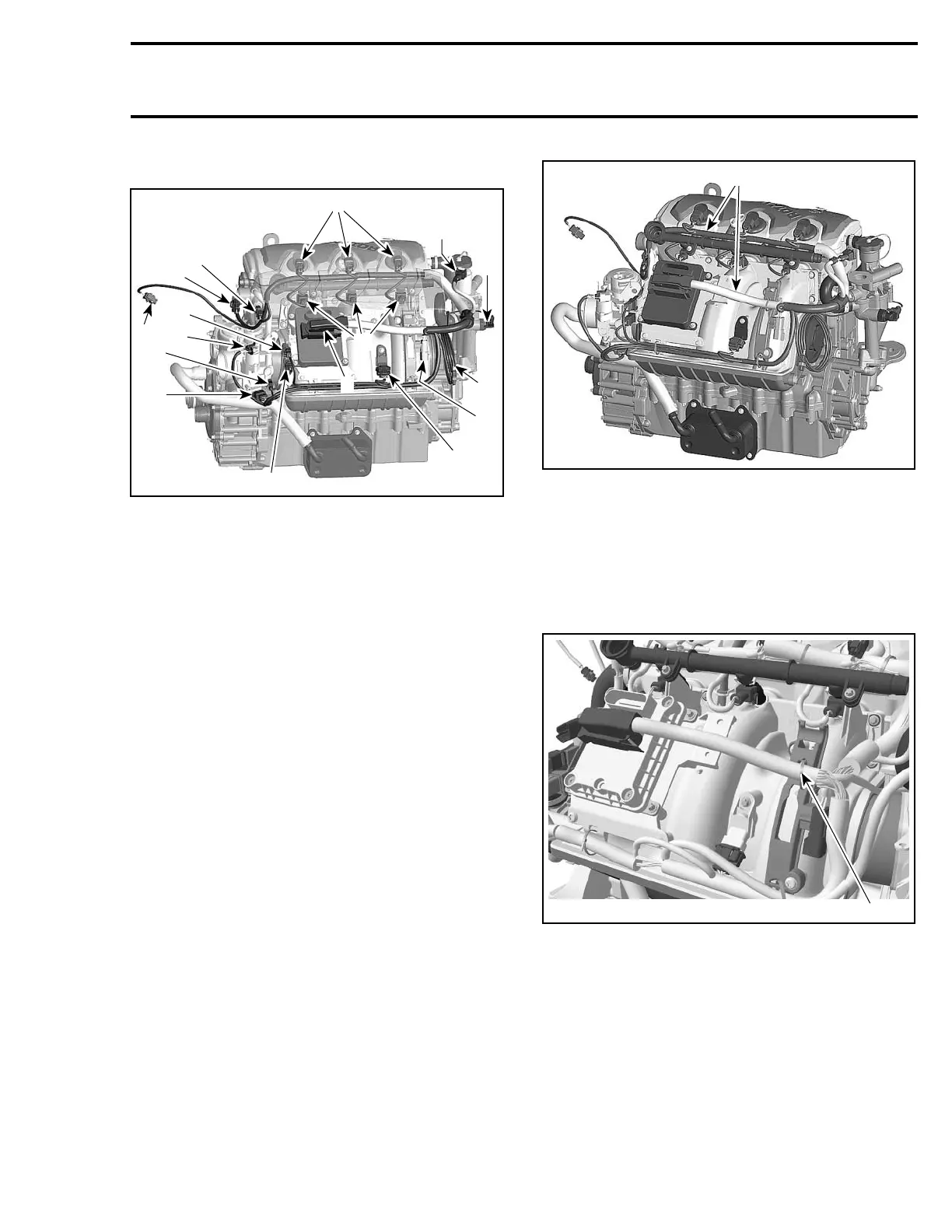

R1503motr323A

1

1. Wiring harness

Remove complete wiring harness.

Installation

First connect the ECM ECU connector A to the

ECM ECU and fix the harness on the wiring sup-

port with a locking tie.

1

R1503motr201A

1. Locking tie

Lead the cable bundle with the injector and igni-

tion coil connectors to the fuel rail and fix it also

by using 4 locking ties.

Te m pla te 193

Loading...

Loading...