Section04ENGINE

Subsection 08 (CYLINDER HEAD AND VALVES)

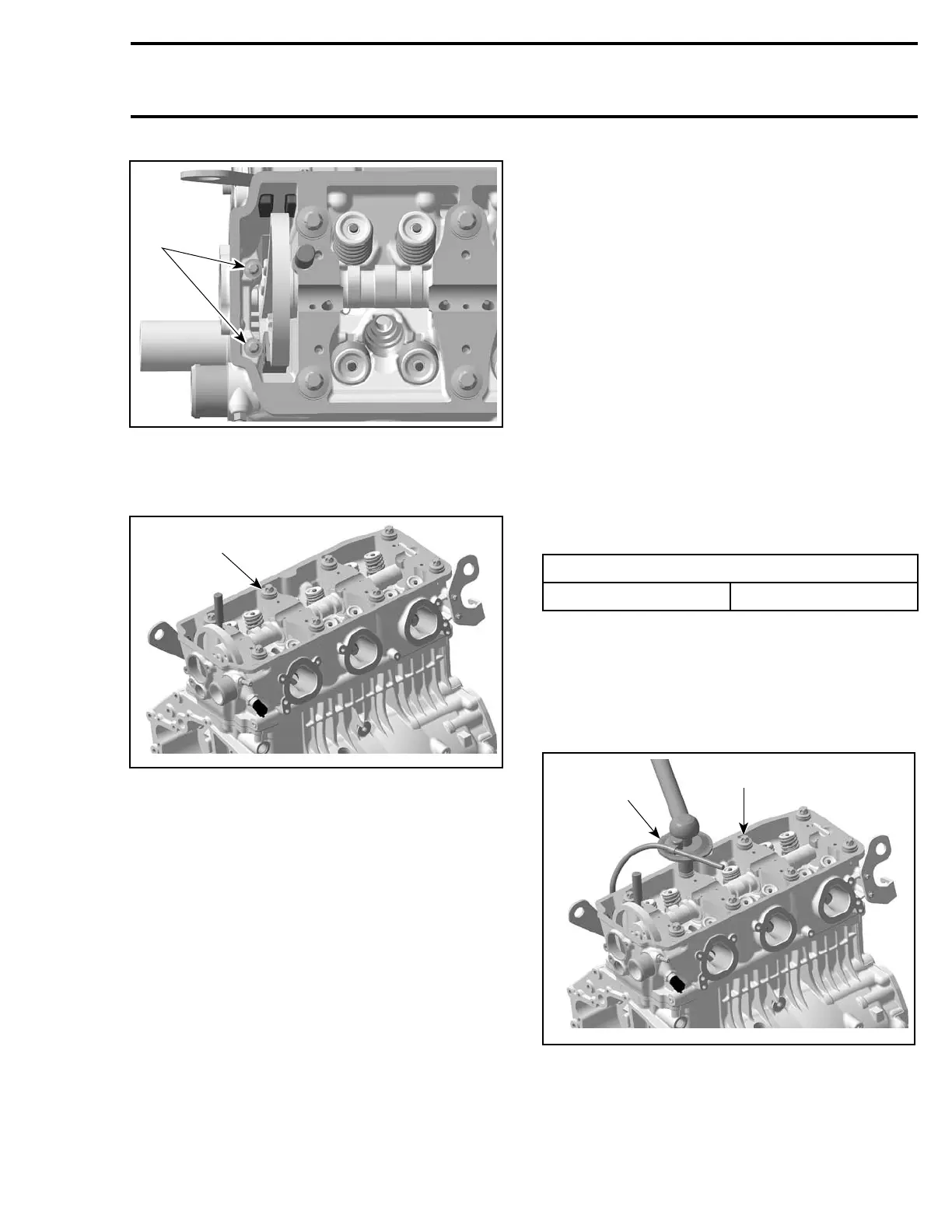

1

R1503motr98A

1. Cylinder head screws M6

– cylinder head screws M11 no. 17 retaining

cylinder head to engine block.

1

R1503motr99A

1. Cylinder head screws M11

Pull up cylinder head no. 18.

Remove gasket no. 19.

Cleaning

Remove carbon deposits from combustion cham-

ber, exhaust port and piston top.

Inspection

Check for cracks between valve seats, if so, re-

place cylinder head.

Check mating surface between cylinder and cylin-

der head for contamination. If so, clean both sur-

faces.

Installation

For installation, reverse the removal procedure.

Pay attention to the following details.

Ensure dowel pins are in place.

Install new cylinder head gasket.

CAUTION: Each installation of the cylinder

head requires a new cylinder head gasket. Us-

ing a gasket twice will cause engine damage,

even if the engine had not run.

Install cylinder screws M11 no. 17.Torque

screws as per following procedure.

CAUTION: This assembly uses stretch screws.

As the screws have been stretched from the

previous installation, it is very important to

measure each screw at assembly. If screw is

out of specification, replace by a new. Failure

to replace screws and to strictly follow the

torque procedure may cause screws to loosen

and lead to engine damage.

CYLINDER SCREW M11

SERVICE LIMIT

148.5 mm (5.846 in)

Torque screws according to following sequence.

First torque to 40 N•m(30lbf•ft).

Then tighten screws turning an additional 120° ro-

tation with a torque angle gauge and finish tight-

eningwitha90° rotation. Torque screws no. 16

to 10 N•m(88lbf•in).

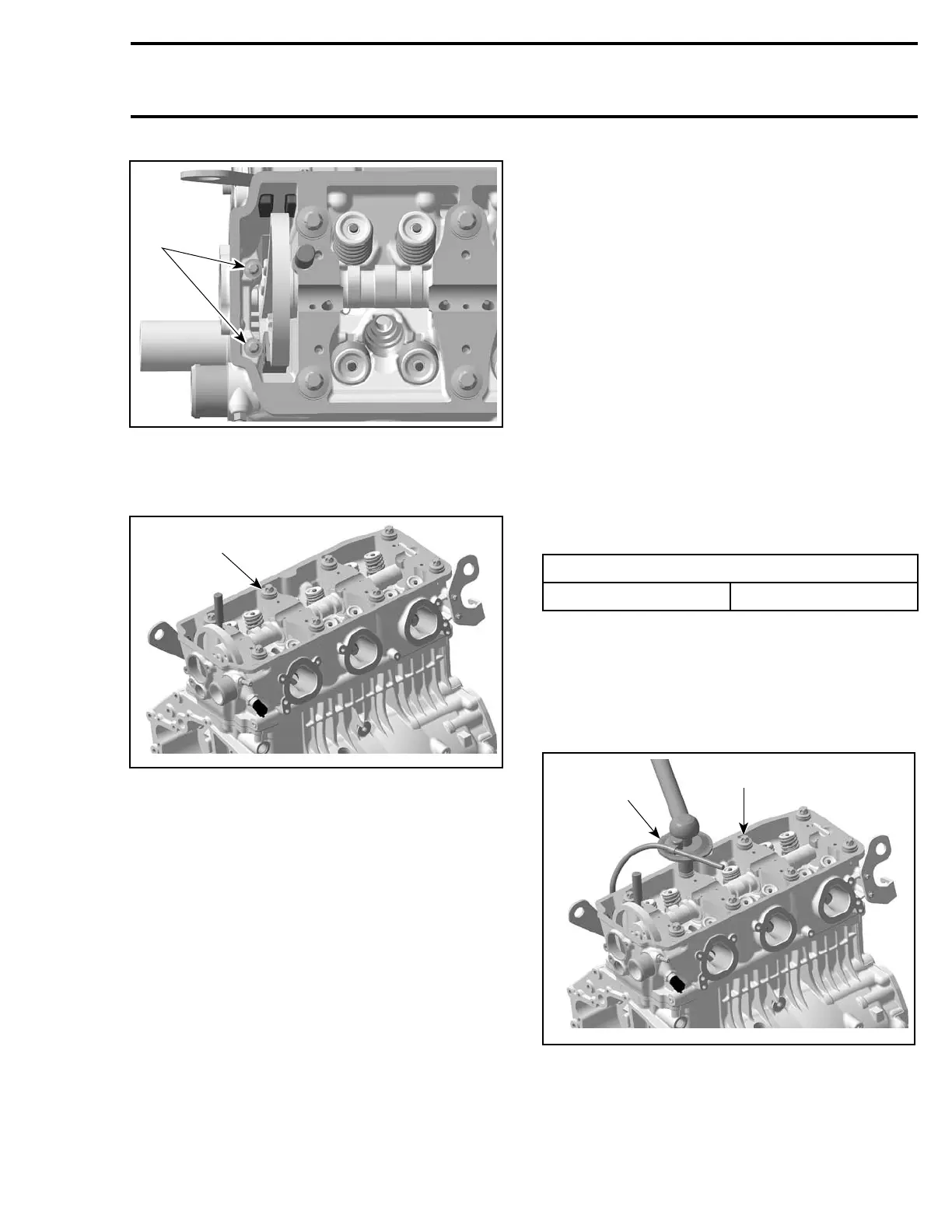

1

R1503motr100A

2

1. Cylinder screws M11

2. Angle torque wrench

Remove crankshaft locking tool then install plug

with sealing ring.

Te m pla te 133

Loading...

Loading...