21

SJ6826RT, SJ6832RT

213560ABA

Base/Engine Section 1 – Scheduled Maintenance

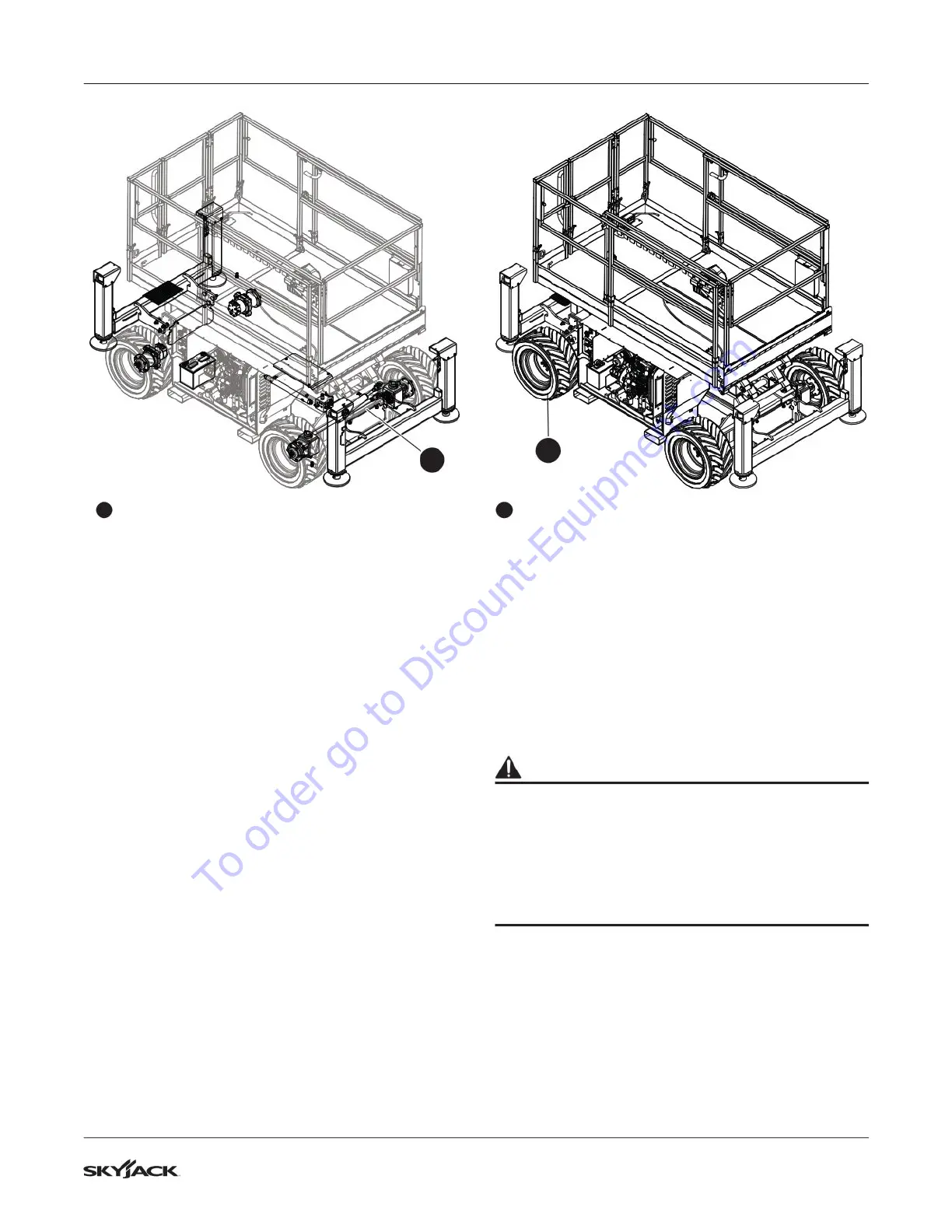

9

Steer assembly (B)

▪ Steer cylinder assembly (B)

▪ Make sure the steer cylinder assembly is

correctly installed.

▪ Make sure there are no loose or missing

fasteners.

▪ Make sure there is no visible damage.

▪ Steer linkages (B)

▪ Make sure there are no loose or missing

fasteners and lock-pins.

▪ Make sure the steer linkages and bushings are

correctly attached.

▪ Make sure there is no visible damage.

▪ Grease points (B)

▪ Make sure there are no loose or missing

fasteners and lock-pins.

▪ Make sure the steer linkages and bushings are

correctly attached.

▪ Make sure there is no visible damage.

▪ Add grease if necessary.

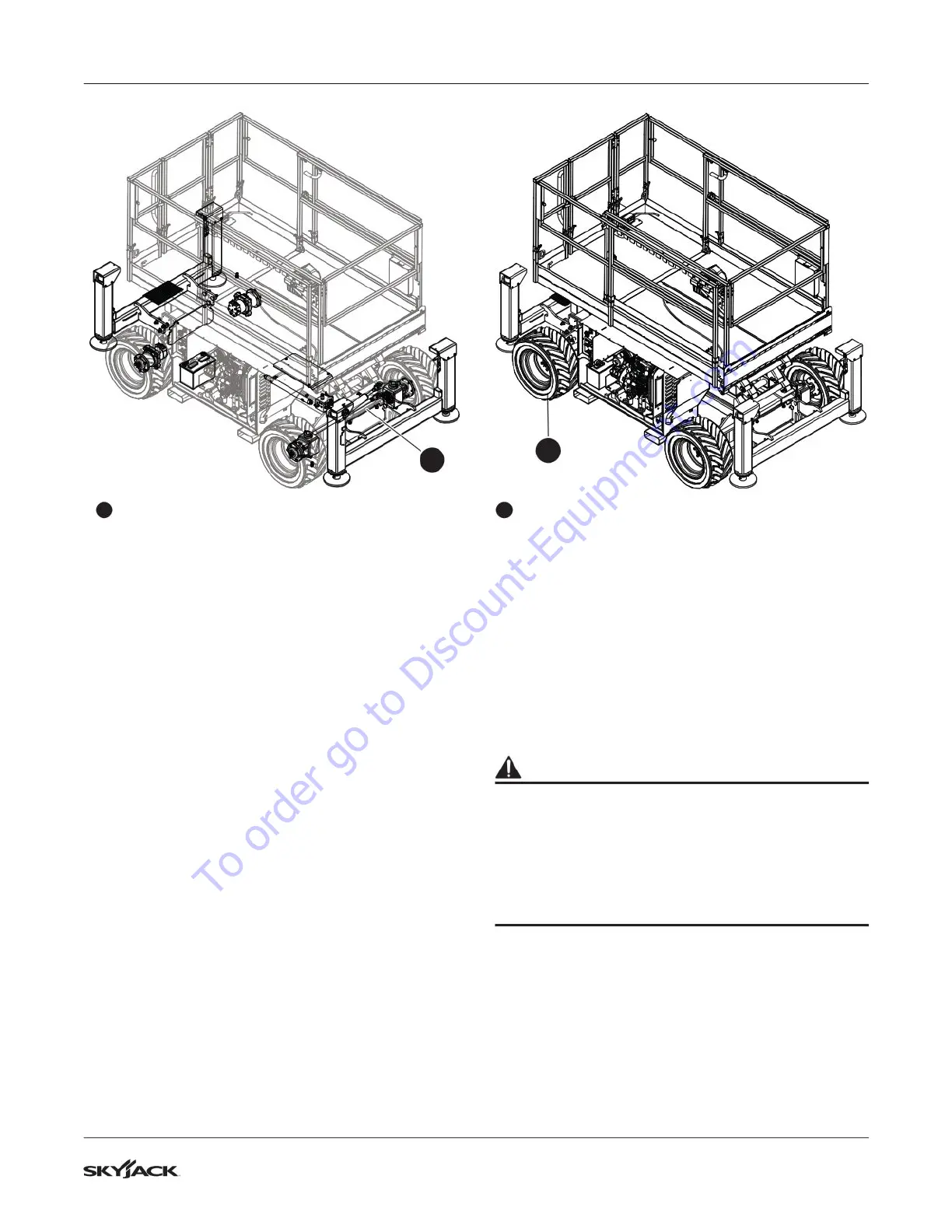

10

Wheel/tire assembly (B,C)

▪ B - Frequent/periodic/pre-delivery Inspection

▪ Do a check on all the tire treads and sidewalls

for cuts, cracks, and unusual wear.

▪ Do a check on each wheel for damage, and

cracked welds.

▪ Make sure the wheels are correctly aligned

vertically and horizontally.

▪ Make sure there is no visible damage.

▪ Do a check on wheel motor assembly for loose

or missing parts and no visible damage.

WARNING

Do not use tires other than the tires that Skyjack

species for this MEWP. Do not mix different types

of tires or use tires that are not in good condition.

Only replace the tires with the same types that are

approved by Skyjack. The use of other tires can

make the MEWP less stable. If you do not obey,

there is a risk of death or serious injury.

▪ C - Annual Inspection

▪ Make sure the castle nut is in position and is

tight.

▪ Make sure the cotter pin is correctly installed.

▪ If the cotter pin is not installed then refer to 24

Torque Specications for Hydraulic Couplings

& Hoses for proper torque information.

9

10

To order go to Discount-Equipment.com

Loading...

Loading...