102 EN/01.2019/G22 © STULZ GmbH – all rights reserved

ec tower technical manual

Installing the servo motor

ufbauplan

Panel

Panneau

E

D

C

B

F

8765

4

3

2

1

8765

4

3

2

1

von

Blatt

Erstelldatum:

Gezeichnet:Entstanden aus:

Norm

Geprüft

Bearbeiter

Datum

Name

Datum

uftrags-Nr.:

Ident-Nr.:

Kunde:

F

Für dieses Dokument und den darin dargestellten Gegen-

stand behalten wir uns alle Rechte vor. Vervielfältigung,

Bekanntgabe an Dritte oder Verwertung seines Inhaltes

sind ohne unsere ausdrückliche Zustimmung verboten.

uftrags-Nr.

Hersteller:

05.91.13.0108/01 EC Tower 91 U

23.10.13

Klußmann

Jobst

0591130108_01

24

=MOD1

0010121 Tie./Schm. 18.09.13 27

Hutschiene mit Schrauben M5x25 befestigt.

1

2

3

-B05

TAM

-T70

1

2

0V2 4V

0V

100VA

Block

-T01

220-460V

PE

M24953

100mm

3

3

-X10

L

PE N

0

1

-F20

2

46

1

35

140M-C2E-C20

A2

A1

A2

A1

A2

A1

A2

A1

2

46

1

35

14

13

-Q70

C09 - C23

-K15

A2

A1

12

14

11

22

24

21

-K17

A2

A1

12

14

11

22

24

21

-K12

A2

A1

12

14

11

22

24

21

-K11

A2

A1

12

14

11

22

24

21

-K21

A2

A1

12

14

11

22

24

21

-K22

A2

A1

12

14

11

22

24

21

-K19

A2

A1

12

14

11

22

24

21

-K08

A2

A1

12

14

11

22

24

21

4

3

-F01

2

1

-F01

2

1

-F02

2

1

-F03

-K10

-F41

1

2

-F10

1

2

T1 T2 T3

N

L1

L2

-Q01

40A

L3 N

-X1

N1

PE1

N2

PE

1

-X4

-X4

-X4

4

-X4

-X4

-X4

-X4

-X4

-X4

1

-X4

-X2

14

-X2

PE1

-X2

A1

-X2

B1

-X2

C1

-X2

B1/GND

-X2

B1

-X2

B1

-X2

B1

-X2

A1

-X2

A1

-X2

A1

-X2

E1

-X2

E1

-X2

4

-X2

B

H8

3644

G

Fuse 5x20

TATA

Rel 1

G

23

24

21

-K70

8

0

20

2

0

0

1

4

0

1

2

3

-B10

optional

optional

Mit Klettband in der

E-Kastentür

befestigen.

$XIEDXSODQ

3DQHO

3DQQHDX

(

'

&

%

)

$

(

'

&

%

$

YRQ

%ODWW

(UVWHOOGDWXP

*H]HLFKQHW(QWVWDQGHQ DXV1RUP

*HSU¾IW

%HDUEHLWHU

'DWXP

1DPH'DWXP QGHUXQJ

$XIWUDJV1U

,GHQW1U

.XQGH

)

)¾U GLHVHV 'RNXPHQW XQG GHQ GDULQ GDUJHVWHOOWHQ *HJHQ

VWDQG EHKDOWHQ ZLU XQV DOOH 5HFKWH YRU 9HUYLHOI¦OWLJXQJ

%HNDQQWJDEH DQ 'ULWWH RGHU 9HUZHUWXQJ VHLQHV ,QKDOWHV

VLQG RKQH XQVHUH DXVGU¾FNOLFKH =XVWLPPXQJ YHUERWHQ

$XIWUDJV1U

+HUVWHOOHU

(& 7RZHU '

7LH6FKP

-REVW

B

02'

7LH6FKP

0,76 8%,6+ ,

7(03 212))

6

;

<

=

;

1

1=1$

1

1111

;

/ 3(

1

7 7 7

/

/ /

)

&(%ELV &(&

&(& ELV &(&

)

&(% ELV &(&

&(& ELV &(&

)

&(% ELV &(&

&(& ELV &(&

)

&(%ELV &(&

&(& ELV &(&

)

&(%ELV &(&

&(& ELV &(&

;$

$% $% $%$%

)

)

)

)

$

$

4

& &

$

$

4

& &

$

$

4

& &

$

$

4

& &

.

$

$

.

$

$

.

$

$

.

$

$

.

$

$

.

$

$

.

$

$

.

$

$

.

$

$

.:

0D[ 0LQ &RP

)XQNWLRQ

(6

%

a

%

% %

$

$

02(//(5

7 7 7

1

/ /

4

$

/ 1

)

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

(

;

(

;

%

;

%

;

%

;

$

;

$

;

$

;

3(=3(3(3(3(3(3(3(3(3(3(

;

$/$/*1' 956(7$%$%

+

*

)XVH [

7$7$

5HO

*2**1'21'5(9(9/6/6&6&6

21

7$ 5DWH

21

5HO

21

$

%

/

/5()

7/57/5

.

%

M26467 M26466

)

&(% ELV &(&

&(& ELV &(&

RSWLRQDO

RSWLRQDO

0LW .OHWWEDQG LQ GHU

(.DVWHQW¾U

EHIHVWLJHQ

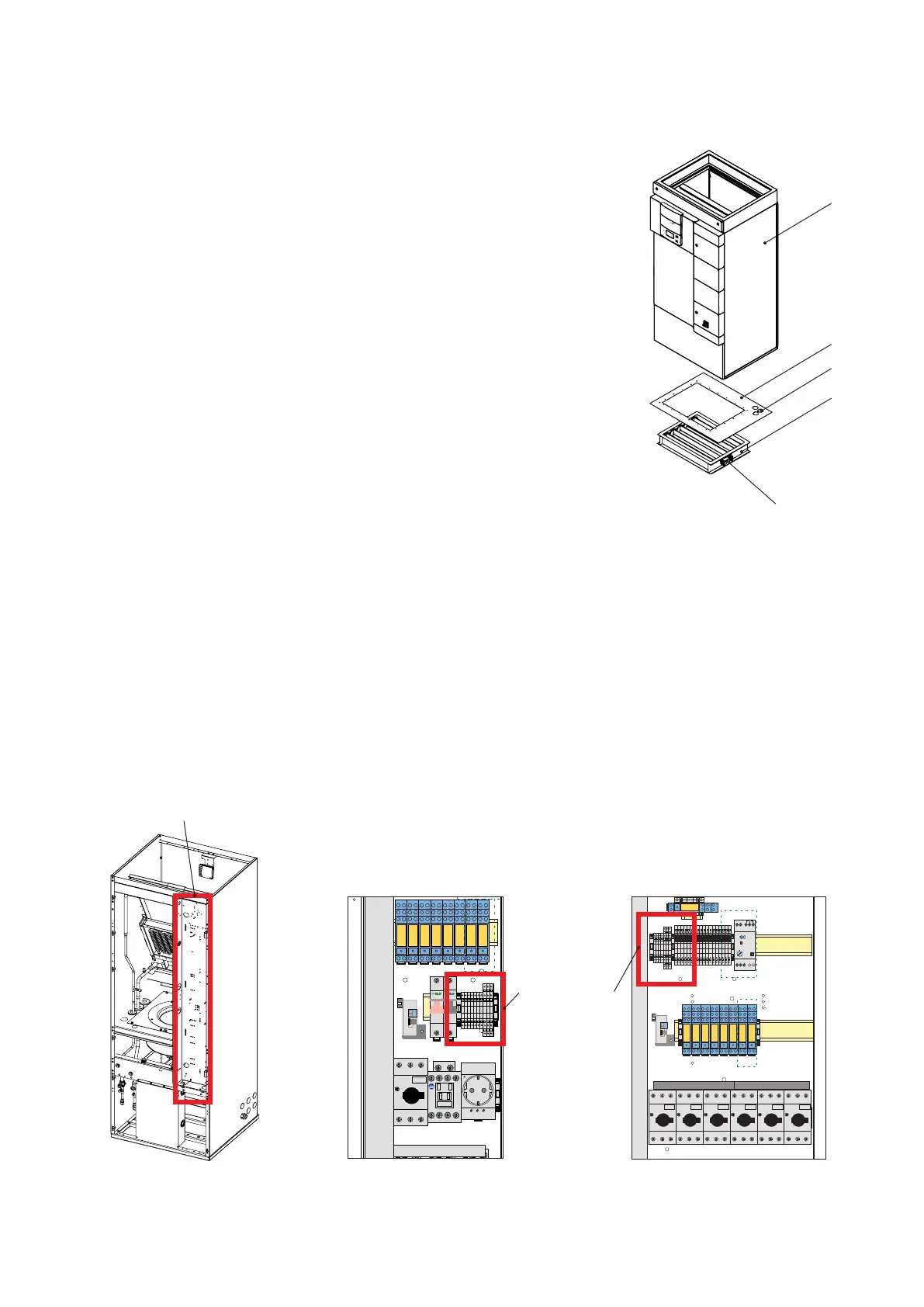

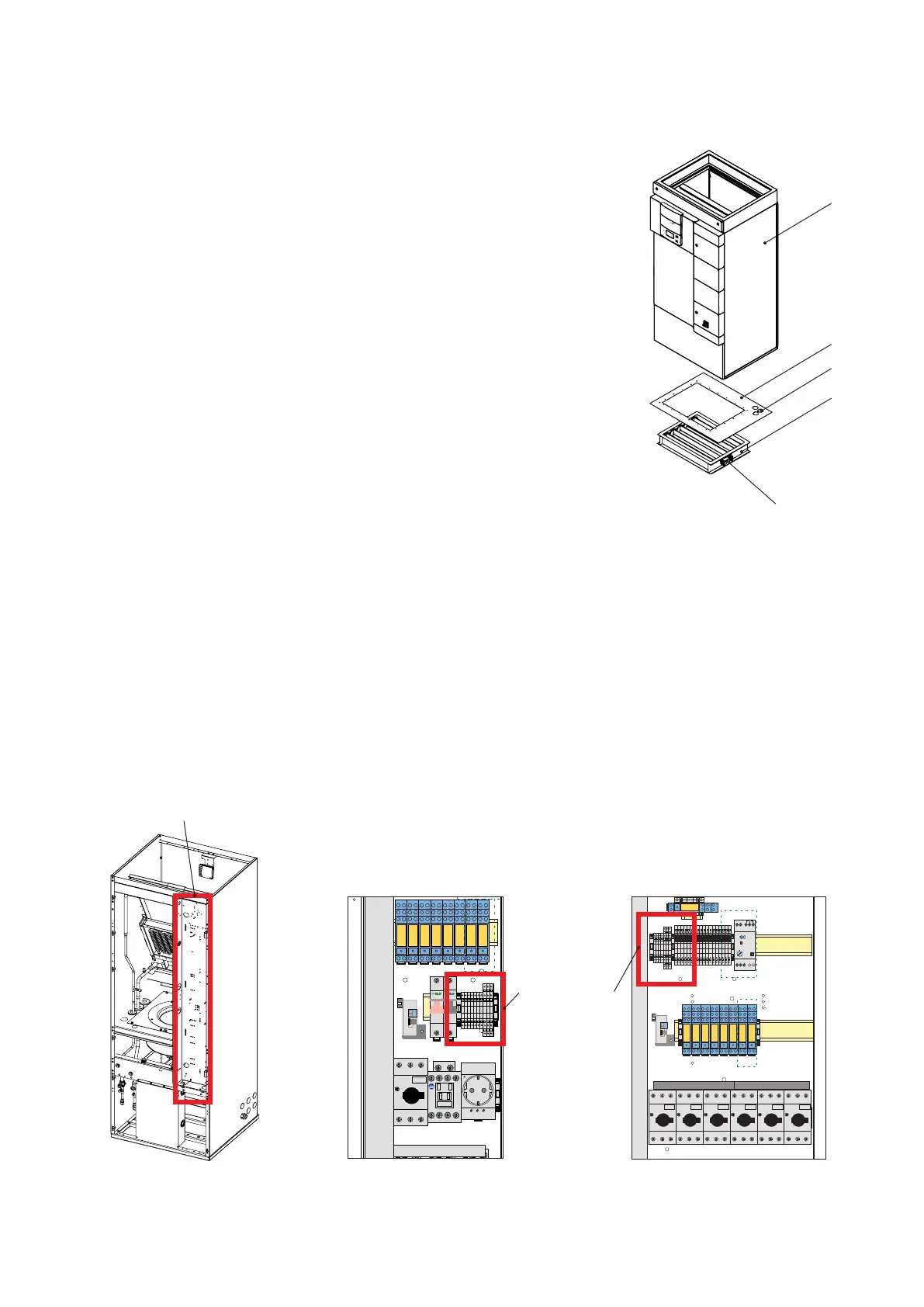

Detail: Junction box 1

Size 1 - ECD/U 91

Junction box 1 Detail: Junction box 1

Size 2 - ECD/U 181/251

Terminals X4

Procedure

1. Install the servo motor (5) on the louver damper (4) as de-

-

stallation instructions for louver damper servo motor“ on page

200).

2. Fit suitable sealing tape between the adapter panel (2) and the

louver damper (4).

3. Install the adapter panel (2) on the louver damper (4) as shown

in the diagram on page 101.

4. Screw the adapter panel and louver damper (4) together.

5. Position and align the adapter panel (2) with the louver damper

(4) on the frame of the raised floor.

the raised floor.

6. Connect the adapter panel (2) and louver damper (4) to the

frame of the raised floor.

7. Position and align the air conditioning unit (1) on the adapter

panel (2).

8. Guide the cable of the louver damper (4) servo motor through

the hole (3) in the adapter panel (2).

9. Connect the servo motor cable in junction box 1 to the terminals (X4) as per the circuit diagram.

- Position of terminal X4: see below.

Size 2

5

1

2

3

4

13.9.2 Electrically connecting the louver damper

EC Tower

51-

5670-16 ECTower_

Vorlage.indd 1

03.08.16 16:31

Loading...

Loading...