191 © STULZ GmbH – all rights reserved EN/01.2019/G22

ec tower technical manual

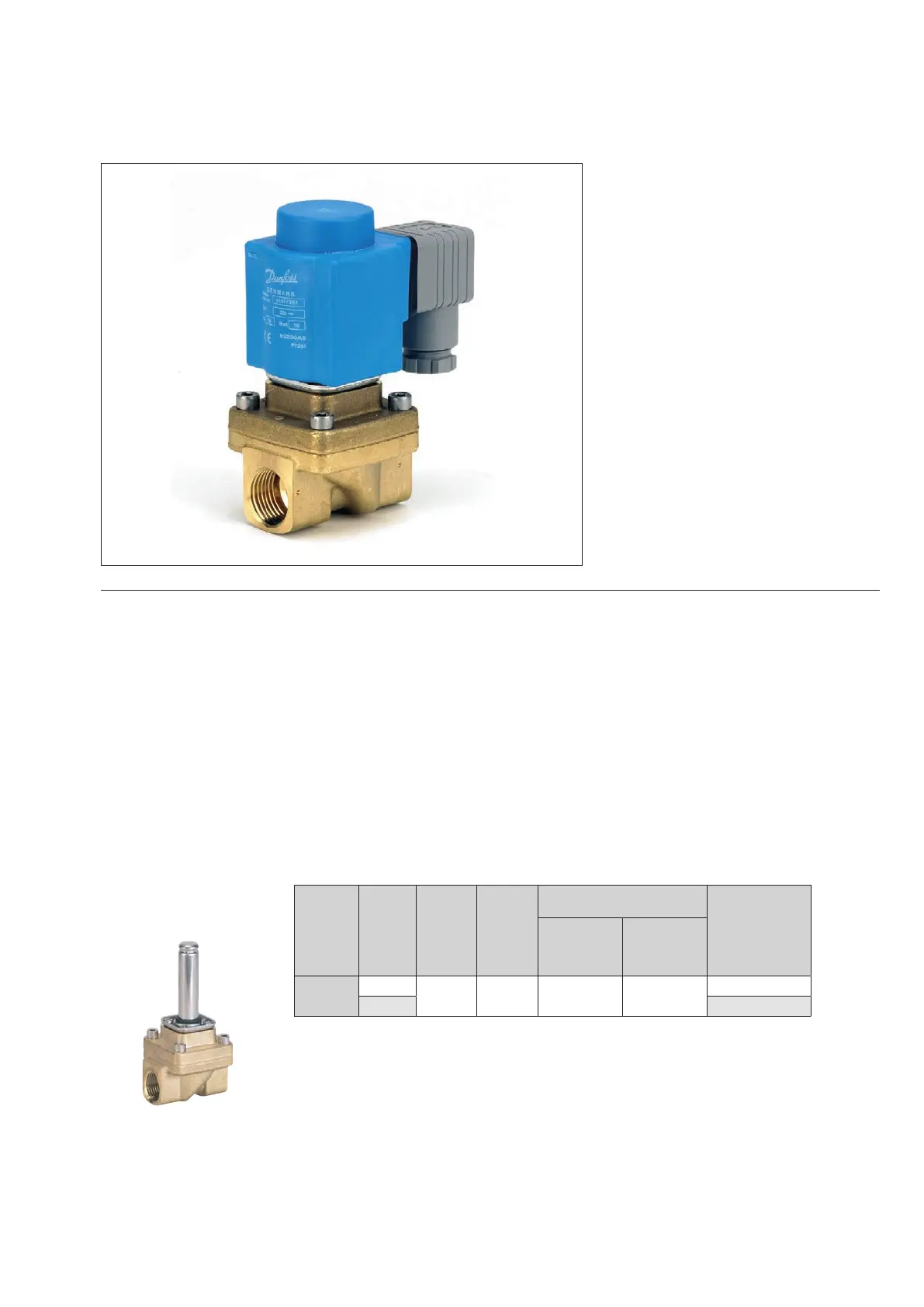

14.4.3 Data sheet for solenoid valve

© Danfoss | DCS (az) |2017.06

Data sheet

Assisted lift operated 2/2-way solenoid valves

Type EV250B

IC.PD.200.H7.02 | 1

• For water, oil, compressed air and similar

neutral media

• Flow range: 0.5 – 20 m

3

/h

• Differential pressure: 0 – 10 bar

• Media temperature from -30 – 140 °C

• Ambient temperature: Up to 80 °C

• Coil enclosure: Up to IP67

• Thread connections: From G ⅜ – G 1

• DN 10 – 22

• Viscosity: Up to 50 cst

• The valve can be used for rough vacuum

• Water hammer damped

EV250B with assisted lift can operate from zero

and up to 10 bar differential pressure.

This 2/2-way valve program is especially to use in

closed circuits with low differential

pressure, but demanding moderate flow rates.

Valve body in dezincification resistant brass for

ensuring a long life even in connection with

aggressive steam media.

EV250B is compatible with the broad Danfoss coil

program with enclosures from IP00 up to IP67.

Medium temperatures up to 140 °C

steam).

• DZR brass version in NC and NO

• Also available with NPT thread

Features and versions:

Connection

ISO228/1

Seal

lair etam Orifice size [m³/h]

k

v

- value

Dierential pressure

min. to max. [bar] / coil type

3

)

Media temperature

min. to max. [°C]

BB/BE 10W AC

BG 12 W AC

BG 20W DC

BN 20 W AC BB/BE 18W DC

4

)

EPDM

1

)

0 – 10 0 – 6

-30–140

FKM

2

) 0–100

G

1

⁄ 2 12 4

1)

EPDM is suitable for water.

-30 – 120 °C: 0 – 10 bar.

120 – 140 °C: 0 – 4 bar.

2)

FKM is suitable for oil and air. For water at max. 60 °C.

3)

Pressure range can be extended to use in rough vacuum, typically up to 99% vacuum (10 mbar), depending on the applica

4)

6 bar max. opening dierential pressure is measured at 6% undervoltage ( 22.6 V DC hot coil), 50 °C ambient and 90 °C media

temperature.

5

) In water applications, exercise the valves at least once every 24 hours, meaning change the state of the valve.

The valve exercise will minimize the risk of the valve sticking due to calcium carbonate, zinc or iron oxide build-up.

Loading...

Loading...