The internal battery is charged in a fully automatic cycle, when the instrument is connected to any external

power source. SV 200A charges itself regardless of whether it is turned on or off. The weather conditions

(i.e. temperature) are taken into account while charging to prevent any damage of the battery caused by

charging in too high or too low temperature.

Note: SV 200A is equipped with the mechanism which protects the internal Li-Ion batteries

from damage caused by critical discharge. When the battery is running flat, the instrument is

automatically switched off.

Note: SV 200A should not be stored for a long time with discharged Li-Ion batteries. Storing

batteries in discharged condition may damage them. If so, warranty for Li-Ion battery is void.

Note: If SV 200A is planned to be stored for a long period of time, it is recommended to charge

its batteries up to 60% of their capacity. Batteries should be charged at least once per 6 months.

3.1.3 External Communication Interface socket

The MULT. I/O socket enables the user to connect the instrument to one of the following devices:

• PC (via USB)

• SP 275 weather station (via RS232)

• alarm lamp (passive, 12V 1A max)

• external trigger (digital input/output signal)

Note: While connecting your SV 200A to a PC by the SC 256A cable, first insert the lemo plug

into the instrument’s MULT. I/O socket and then the USB plug into the PC!

3.1.4 LAN socket

LAN socket is used for connection SV 200A to the local area network using SP 200 adapter.

3.1.5 Antenna sockets

There are two antenna sockets: for 3G and WLAN communication.

After plugging the antenna into the socket, the screw should be tightened to light resistance only. Do not

over tighten this connector.

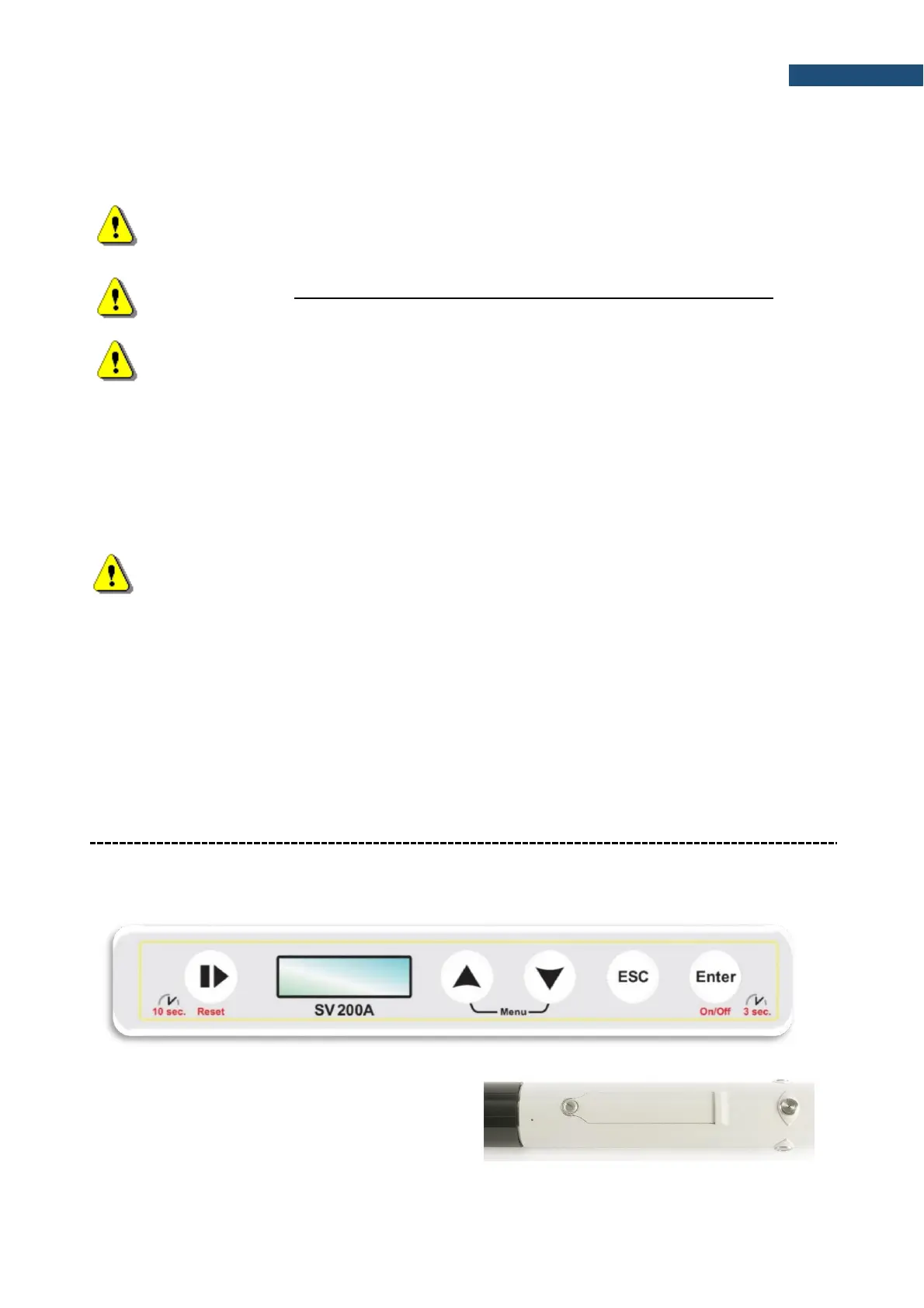

SV 200A is dedicated for the outdoor monitoring and remote control via mobile 3G network, LAN or WLAN.

However, it can be also controlled from the control panel with the use of five keys and a display (128 x 32

pixel resolution).

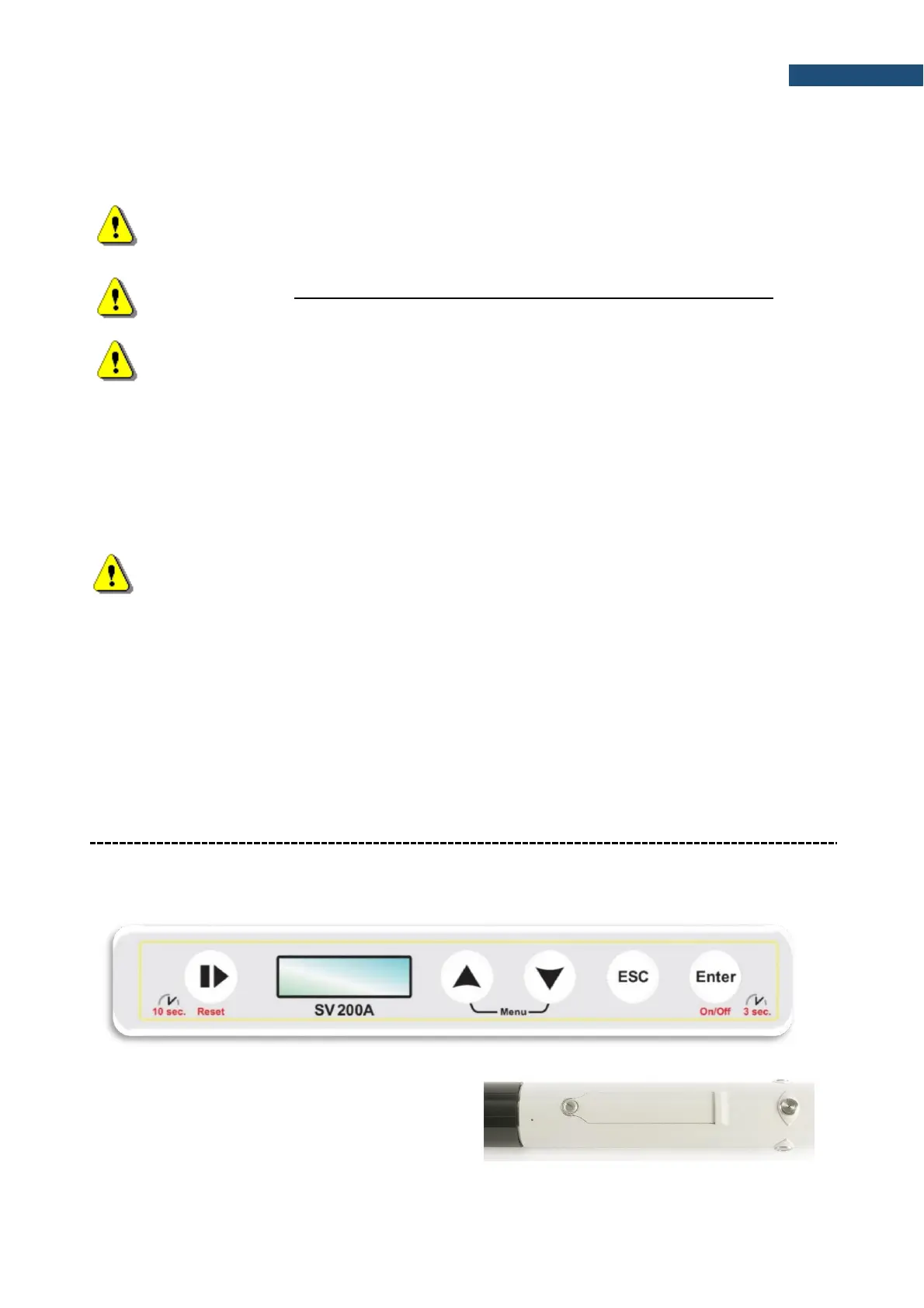

During outdoor operation, the control panel should

be closed by the flap. Closed flap assures protection

of the instrument’s user interface from environmental

impact and, what is more important, assures that

acoustical direction characteristics are within

declared tolerances.

Loading...

Loading...