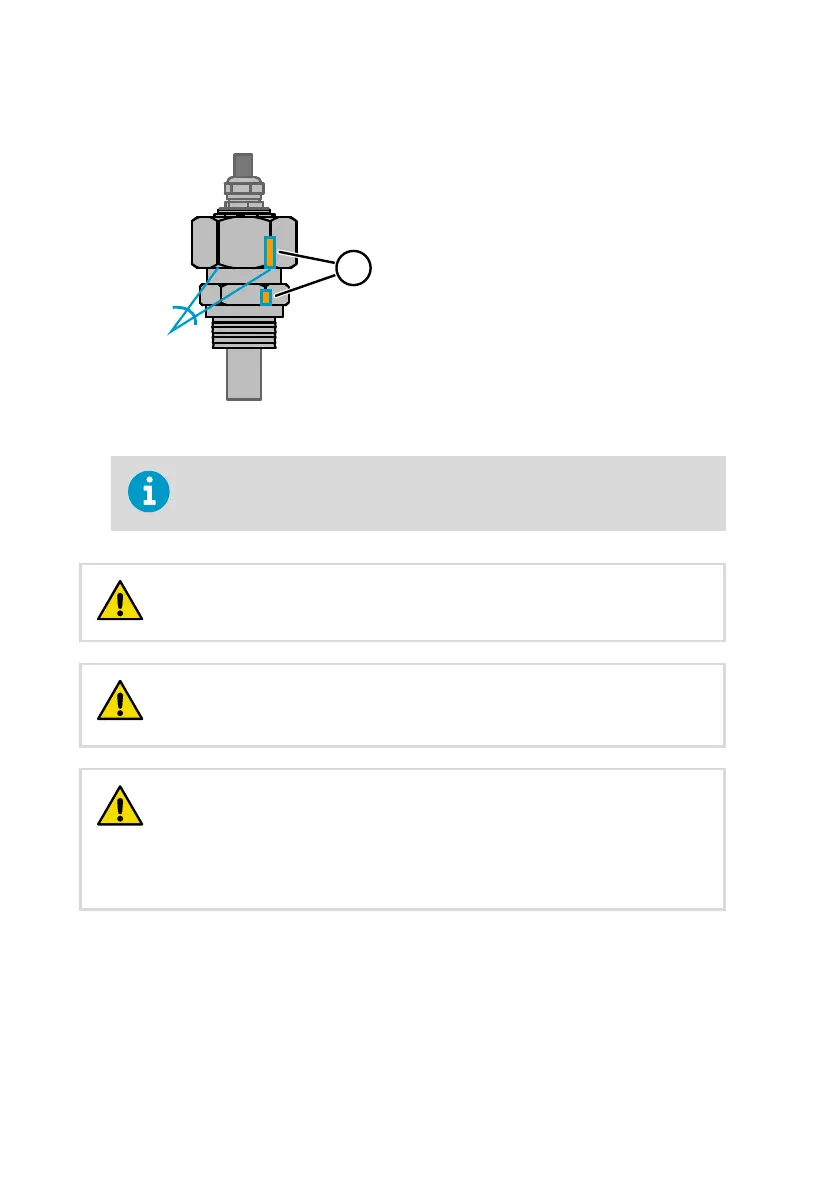

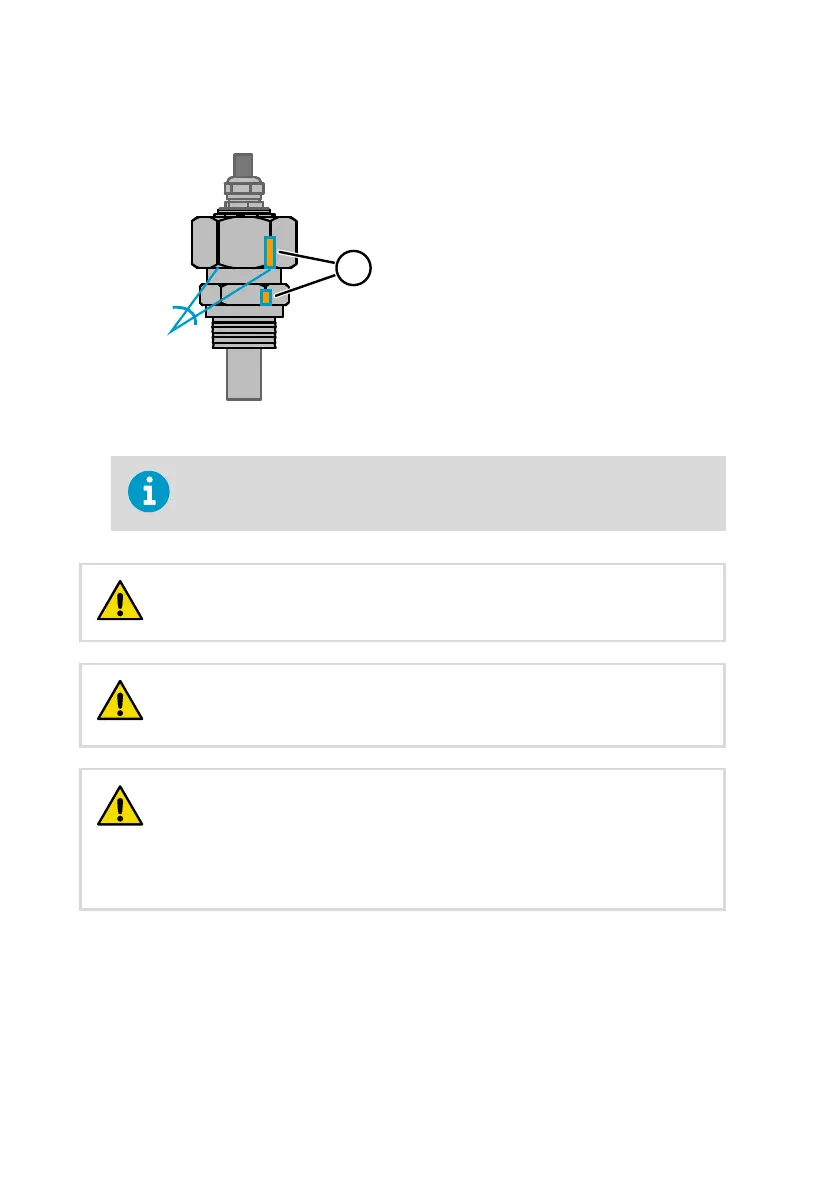

4. Tighten the nut a further 50-60° (approximately 1/6 turn) with a wrench. If you have

suitable torque wrench, tighten the nut to max 45 ± 5 Nm (33 ± 4 ft-lbs).

1 Draw a line on the clasp nut hex and the fitting body hex to mark the 50-60° (1/6)

turn tightening rotation.

Take care not to overtighten the clasp nut to avoid diculties when opening

it.

Take care not to damage the probe body. A damaged body makes

the probe less tight and may prevent it from going through the clasp nut.

CAUTION!

In pressurized processes it is essential to tighten the supporting

nuts and screws very carefully to prevent loosening of the probe by the action of

pressure.

CAUTION!

When HMP378 is installed in a process with a pressure diering

from normal atmospheric pressure, you must enter the pressure value of the

process as an environmental compensation in order to receive accurate

measurement results. For information on entering environmental compensations

with the transmitter display interface or Vaisala Insight PC software, see

Environmental compensation and measurement settings overview (page 114).

CAUTION!

HMT370EX User Guide M212305EN-B

74

Loading...

Loading...