6.5 System parameters

The system parameters are different for every type of conveyor (Breaker, Carcass and

Tread).

The parameter values are stored in the VVS parameter file VVS_Prm.ini.

The default parameter values stored in the VVS parameter file VVS_DefPrm.ini.

Some system parameters deal with calibrations. For example, the 'Counts Per Meter'

parameter value is determined during encoder calibration.

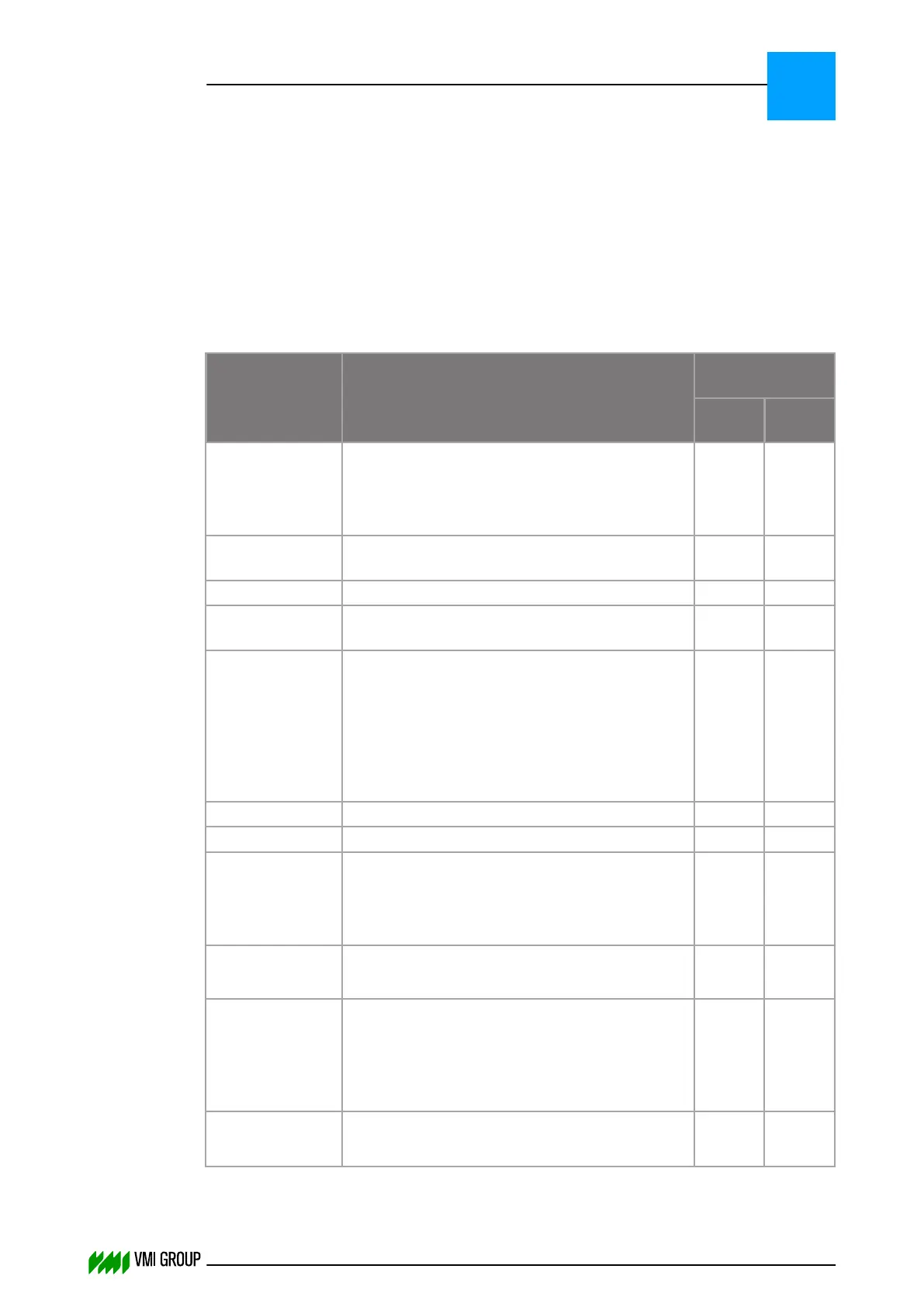

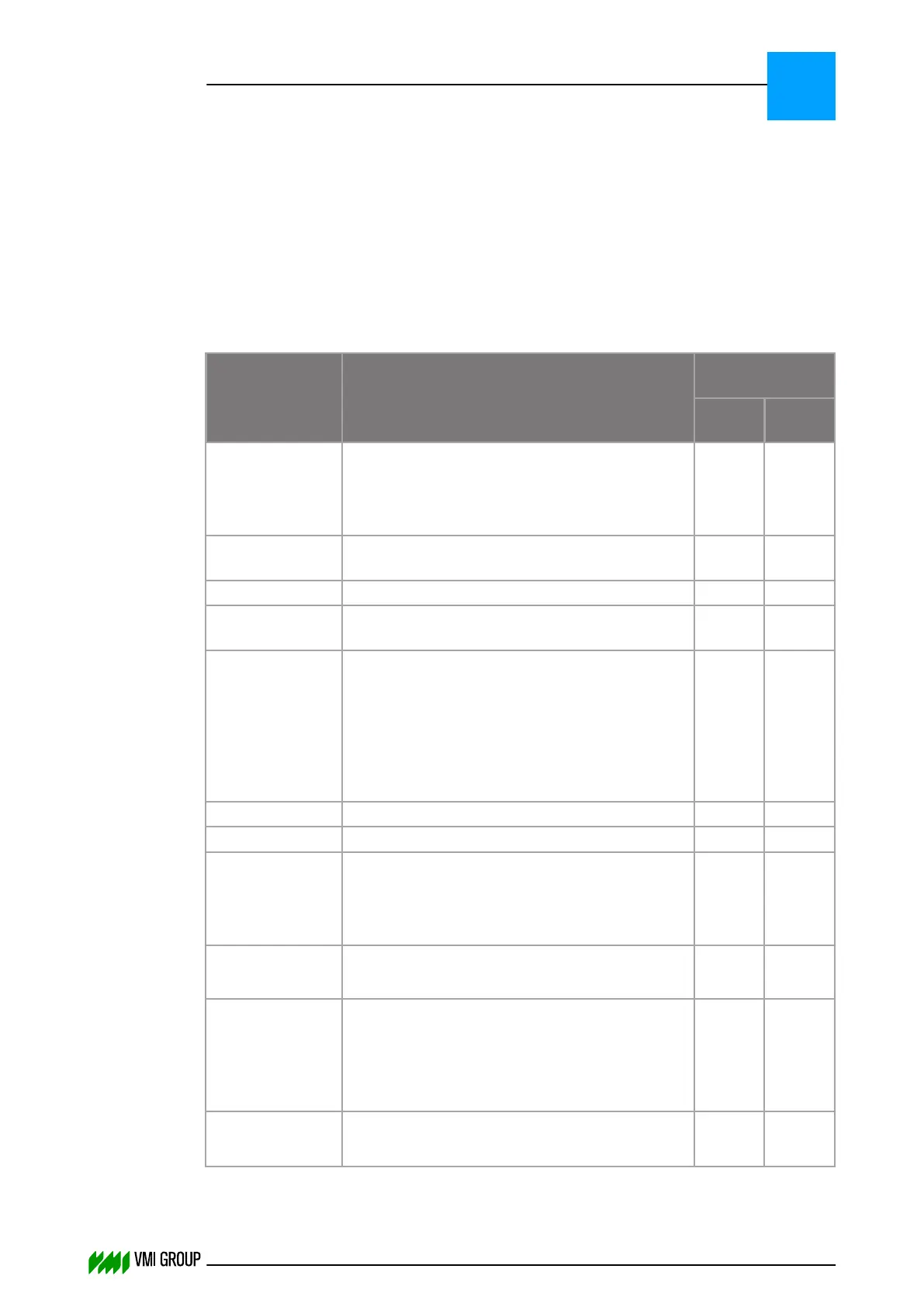

6.5.1 Default breaker system parameters.

Parameter Description Recommended

values

Pass.

TBMs

Truck

TBMs

Counts Per Meter

1

Pulses per meter of the encoder.

Usually encoder calibration is started by the PLC.

For more information, refer to the paragraph

Encoder calibration on page 5

‑

23.

xxxx xxxx

Clamp Position Length passed under camera before the clamp is

lowered.

20.0

mm

20.0

mm

DogEar Tolerance Dog ear detection tolerance. 0 mm 0 mm

DogEar

Response

Percentage of the dog ear that will be

compensated.

0 % 0 %

Delta Body If width increases less than 0.5 mm in 50 ms

the breaker algorithm switches over to body

centering.

If 0 is entered here, the PLC has to take care of

the switch from LE to Body by setting the

command bit (refer to Command buffer on

page 6

‑

14).

5 mm 5 mm

Template Width Reserved for future use - -

Width Offset Reserved for future use - -

Tip‑P Proportional Gain tip.

P Parameters of the PID loop camera, VVS

controller, actuator used during centering of the

first Delay Clamp ms of the leading end.

20 3

Tip‑D Differential Gain tip.

D Parameters of the same loop controller.

50 10

Body‑P Normal Proportional Gain.

P Parameters of the PID Loop camera, VVS

controller, actuator used after Delay Clamp ms

passed, so a part of the leading end, body and

trailing end is centered with these parameters.

30 3

Body‑D Normal Differential Gain.

D Parameters of the same loop controller.

50 10

PARAMETERS

System parameters

6

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592

6-22

Loading...

Loading...