6.3 Command buffer

The Command buffer contains 1 word of 16 bits for each conveyor. Each bit represents a

single command like 'start centering', 'reset centering', etc.

The commands are read from the PLC by the OPC every 100ms and are sent to VVS

during system start up, size change, etc.

Length: 1 word (16 bits) for each conveyor (Breaker 1, 2, 3, 4, Carcass and

Tread).

Information: The commands to the centering system, such as start centering, reset

centering etc.

Function: The OPC reads every 100ms and sends to VVS at any change of state of

internal commands.

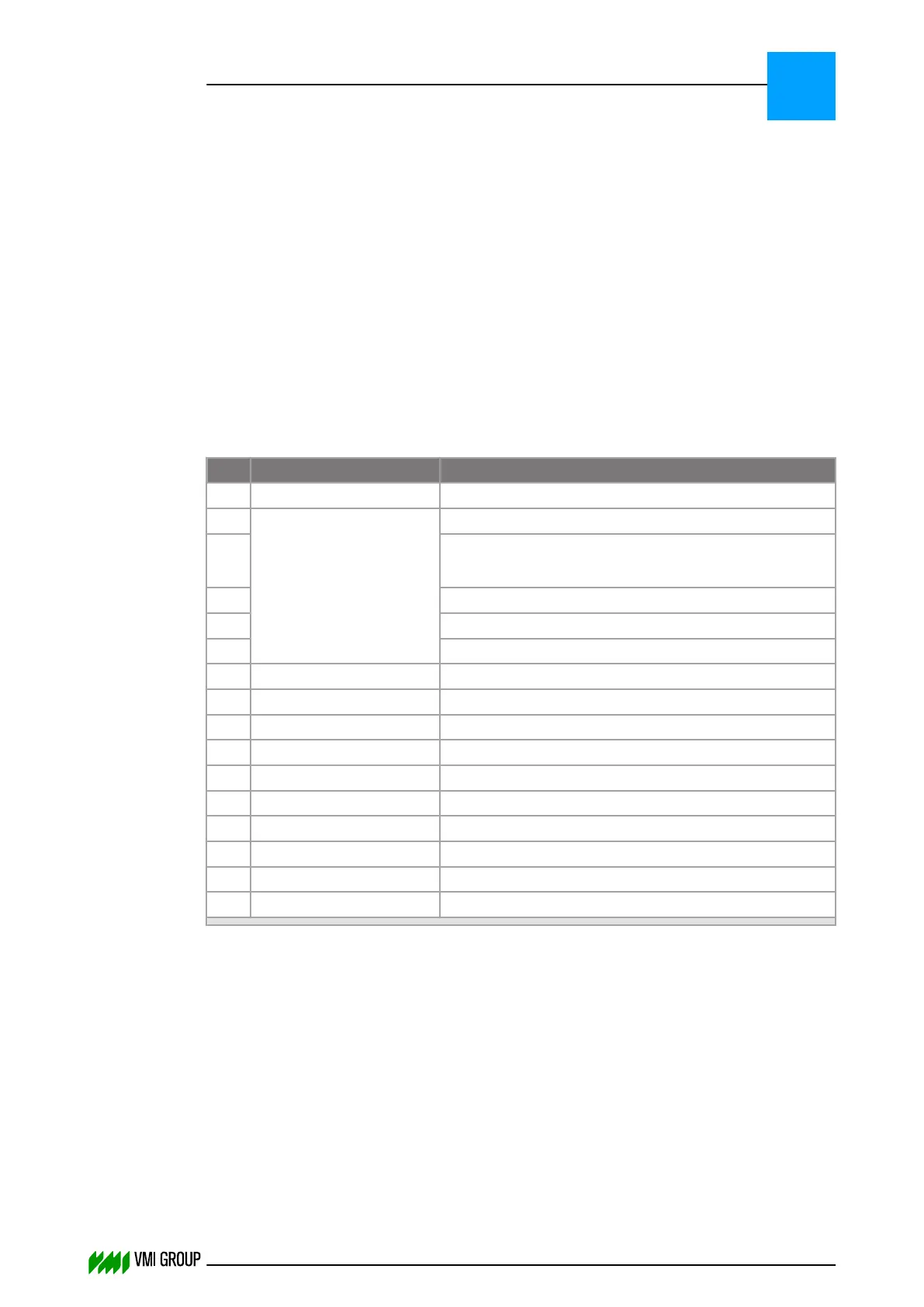

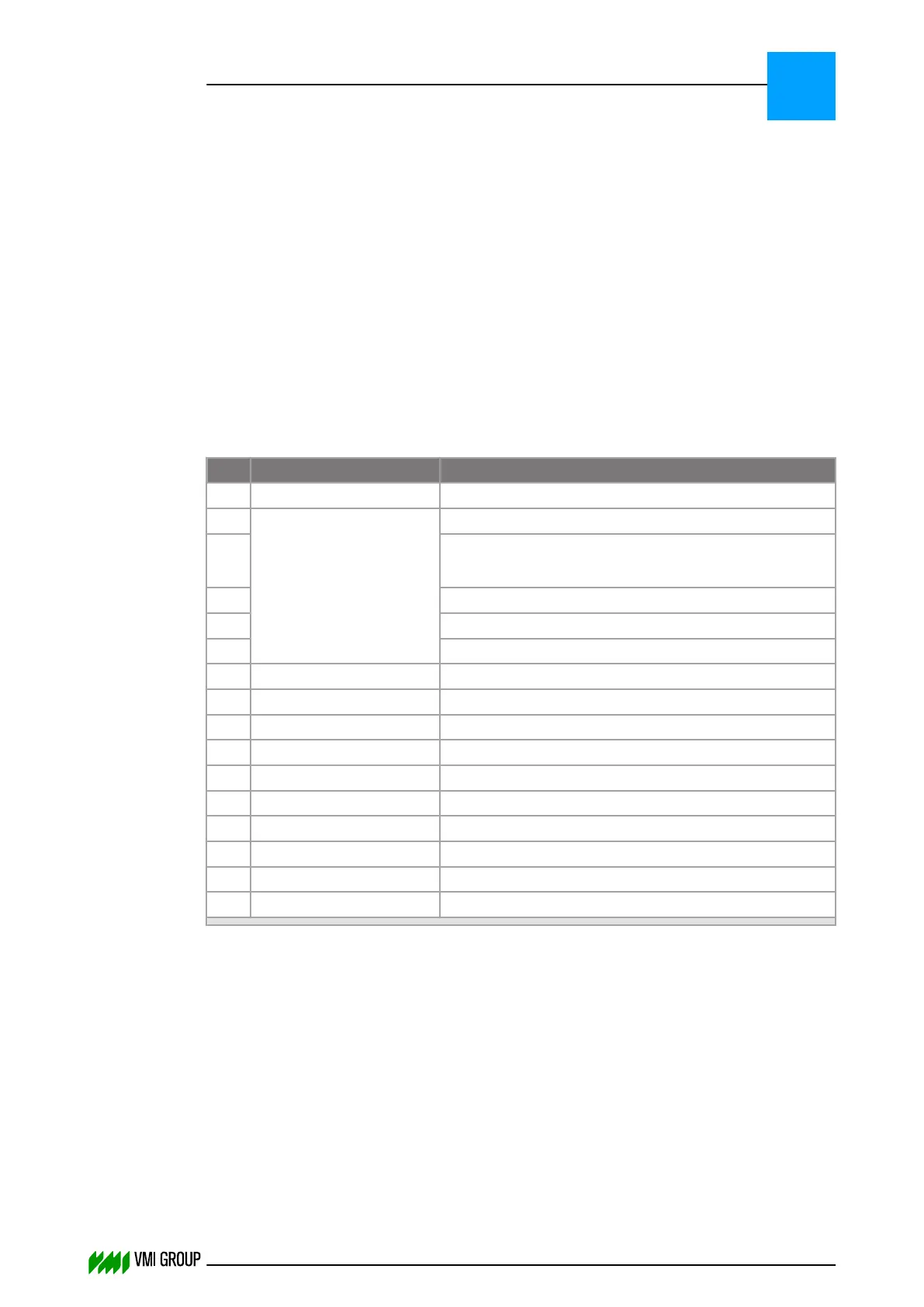

6.3.1 Command parameters

Bit Command signal Remarks

0 Home conveyor -

1 Center material In Carcass: Center PA

2 In Carcass: Center BP 1

In Tread: Scan profile tread

3 In Carcass: Center BP 2

4 In Carcass: Center Sidewall

5 In Carcass: Center Innerliner

6 Jog left -

7 Jog right -

8 Send Parameters Used for handshake (A)

9 Reset actuator Issue a device reset of the actuator unit (B)

10 Switch to body Only Breaker

11 Switch to trailing end Only Breaker

12 Spare -

13 Calibrate encoder Encoder calibration for Breaker and Tread (C)

14 Hold conveyor -

15 Clear width compensation Clear width difference compensation

PARAMETERS

Command buffer

6

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592

6-14

Loading...

Loading...