Word Parameter Dimension

13 Spare

14 Calibration length 0.1 mm

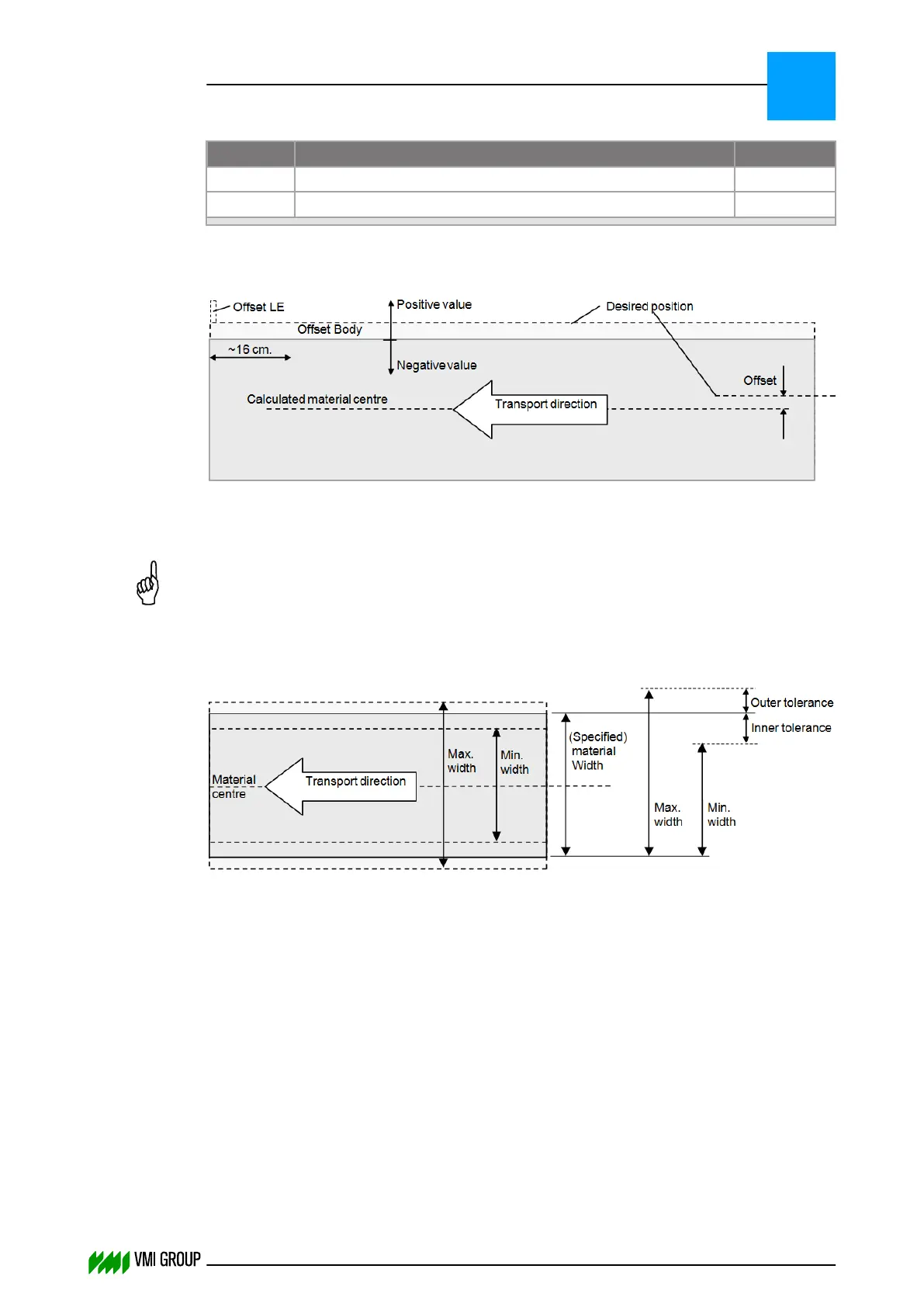

6.2.3.1 Offset

Offset LE and Offset Body shift the center line to the right (positive value) or to the left

(negative value).

NOTICE

Left / right is determined by the flow of the material.

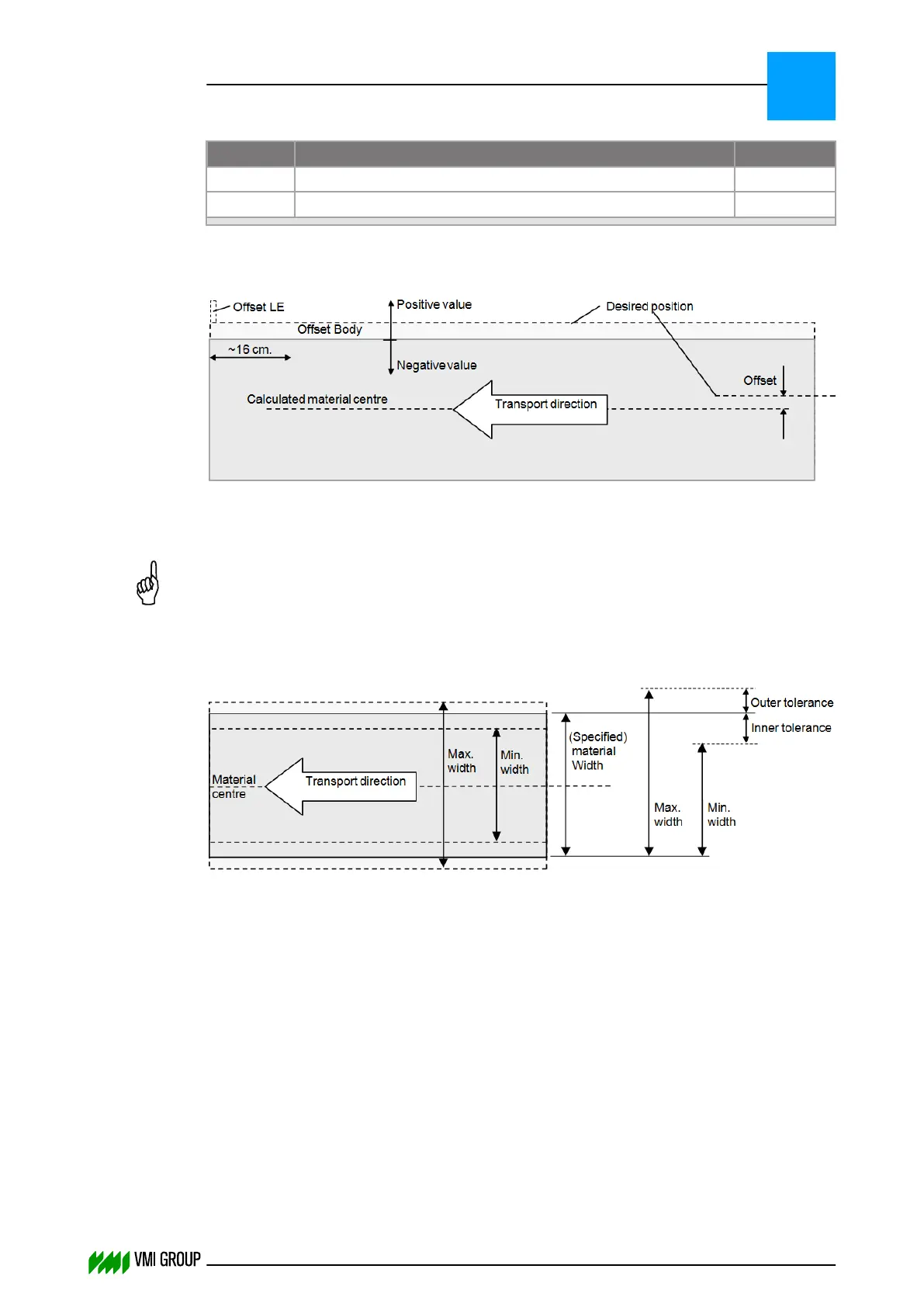

6.2.3.2 Width and width tolerances

Tread width + Tread outer tolerance = maximum allowed tread width.

Tread width – Tread inner tolerance = minimum allowed tread width.

The measured material width is the running average over 21 samples and compared to the

specified material width.

When the measured material width is outside the tolerance, an error message is given.

6.2.3.3 Calibration length

The Calibration length is a calibrated movement of the conveyor, set by the PLC during

calibration of the encoder for length measurement.

Encoder pulses are counted during conveyor movement over a length set by calibration

length. From this the 'counts per meter' is calculated.

For more information, refer to the paragraph Encoder calibration on page 5

‑

23.

PARAMETERS

Parameter buffer

6

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592

6-13

Loading...

Loading...