8.4 Breaker centering problems

8.4.1 Breaker centering switches too late to TE center mode

Problem:

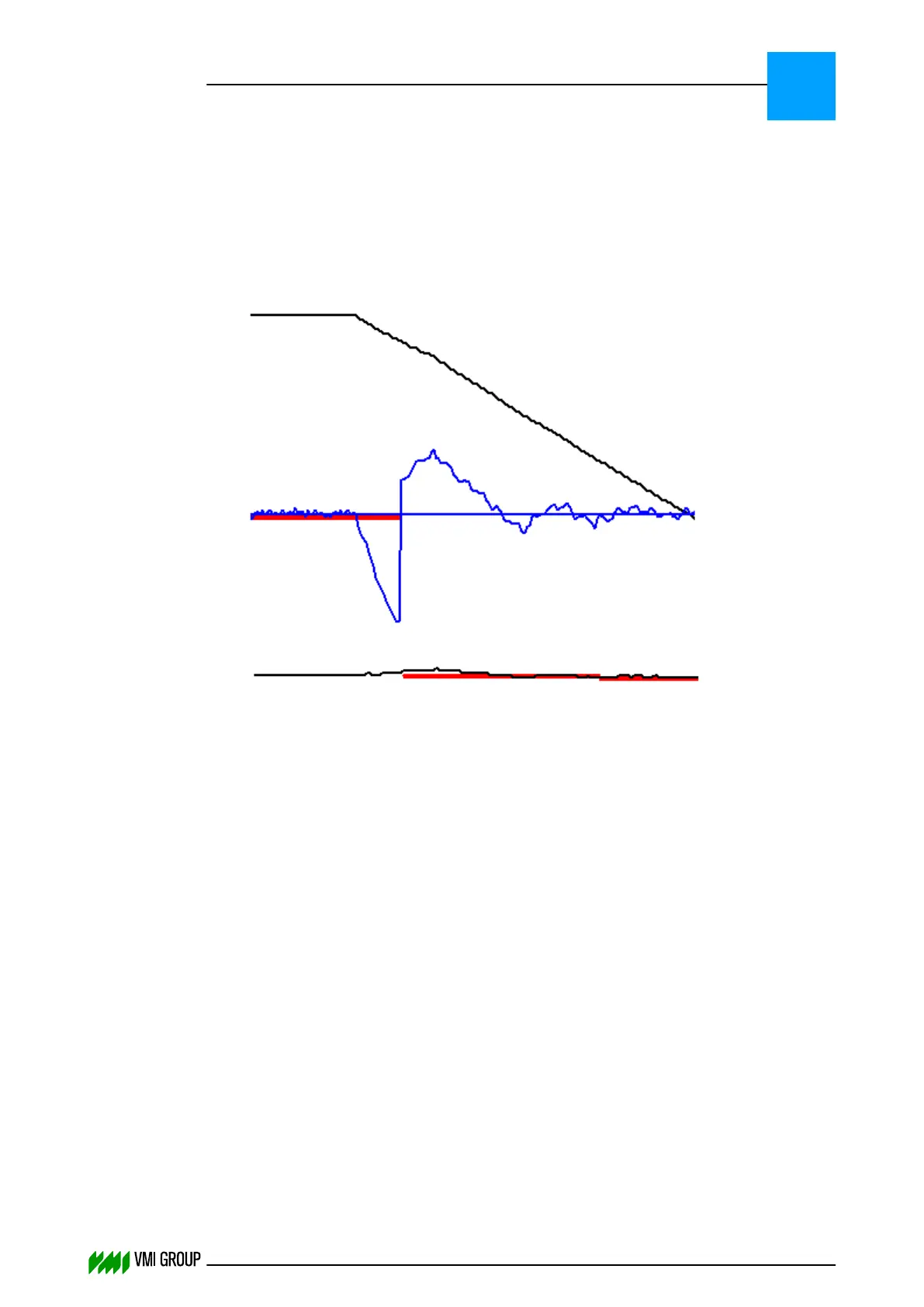

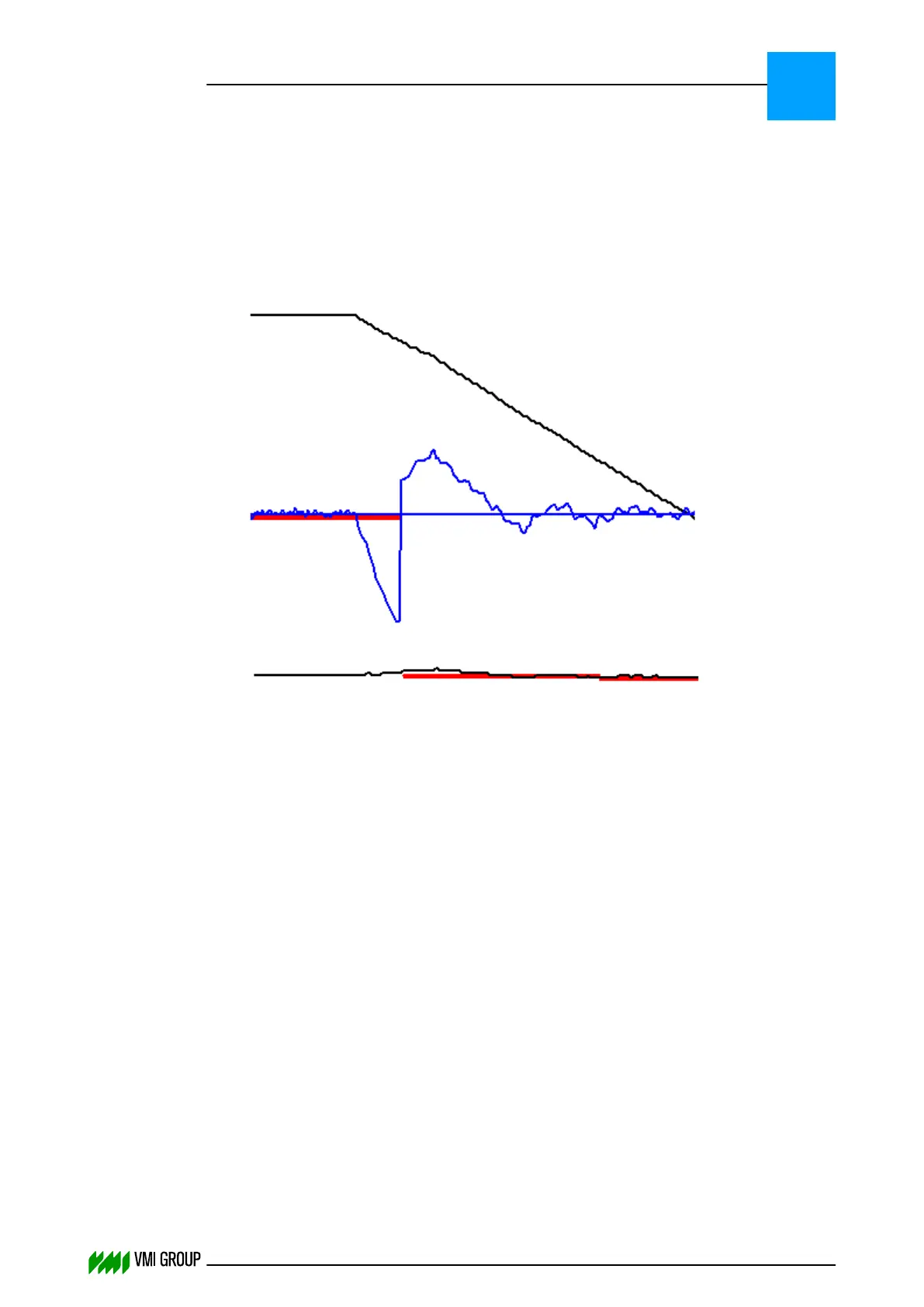

When breaker centering switches too late to TE center mode, it will result in bad centered

material. An example of this behavior is shown in the following material scan.

Cause:

VVS can switch to TE center mode on the following conditions:

● Switch to TE command received from the PLC.

● Switch to TE based on length. Using the parameter breaker length, VVS can calculate

the start of the TE. Using this info it will automatically switch to TE. The calculated

switching point is 30 mm prior to the start of the TE. This functionality is only available

on TBMs equipped with a BK5120 encoder module.

● If the breaker width is less than 15 mm of the breaker parameter width. VVS will

automatically switch to TE center mode.

The main cause of this problem is that the PLC does not send the 'Switch to TE' command

on time to the VVS. Because this TBM is not equipped with an encoder, it can only switch

to TE center mode based on the PLC command or decrease of the width. In this example

VVS continues to position the material using body center mode until a critical width

decrease is measured. After which it will automatically switch to TE center mode.

Solution:

Make sure that the PLC sends the switch to TE command on time.

TROUBLESHOOTING

Breaker centering problems

8

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592

8-16

Loading...

Loading...