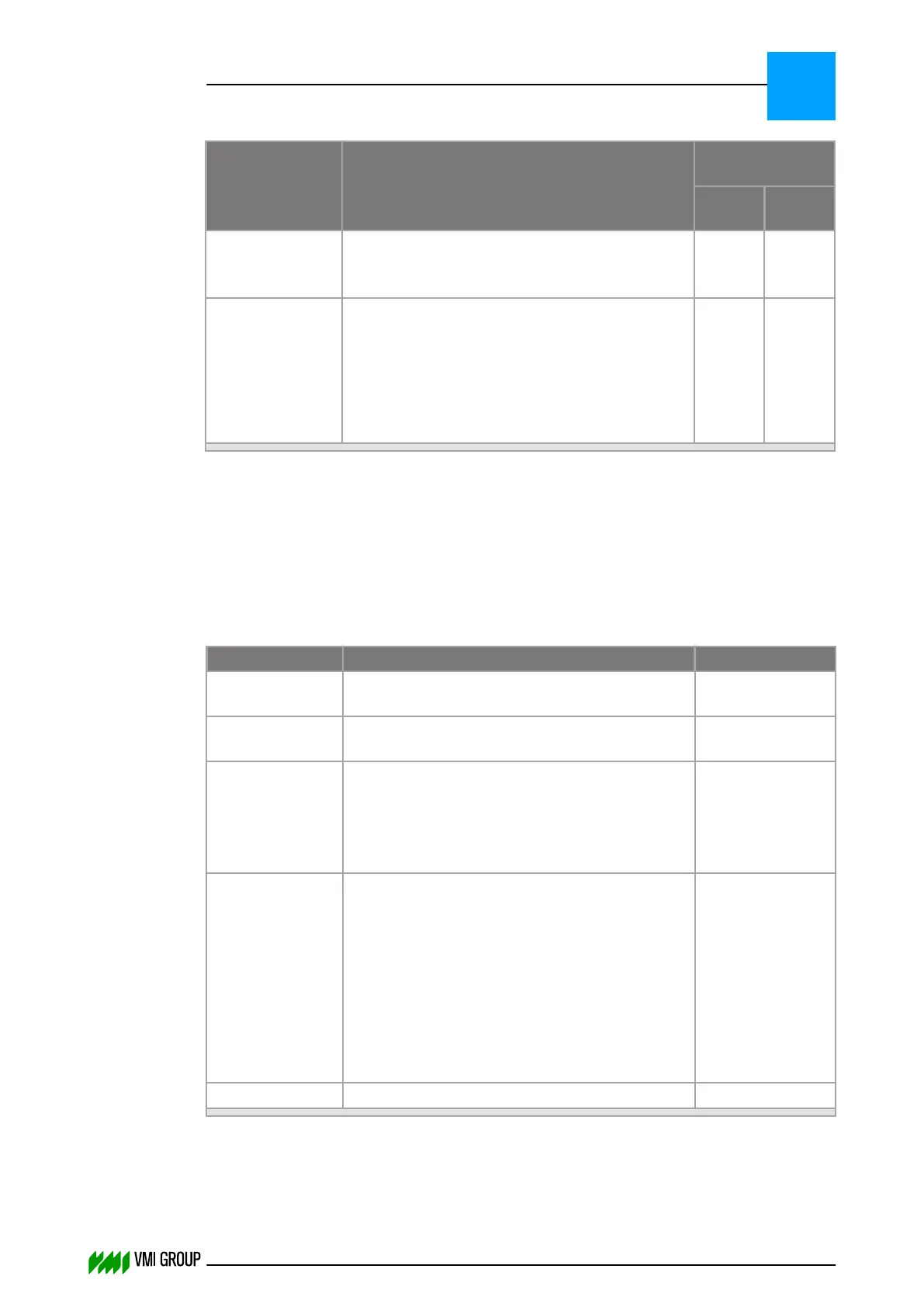

Parameter Description Recommended

values

Pass.

TBMs

Truck

TBMs

Reference

Width‑P

Reference width for GAIN scheduling

2

.

For every material width another value for the

Body‑P parameter is calculated.

100 mm 100 mm

Gradient‑P

Gradient for GAIN scheduling

2

.

The P parameter for body centering is modified

according to the relation:

P = Body‑P + (Material Width - Ref Width‑P)

´ Gradient‑P / 100.

Where the Material Width is the width of the

current breaker.

0 1/mm 0 1/mm

Notes:

1. This value is determined after calibration of the encoder counter.

2. GAIN Scheduling is used to get better performance for wide breaker material.

Typically, use a P value of 30 for small material (between 100 mm and 300 mm).

When the material is wider then 300 mm it is recommended to use a P value of 80.

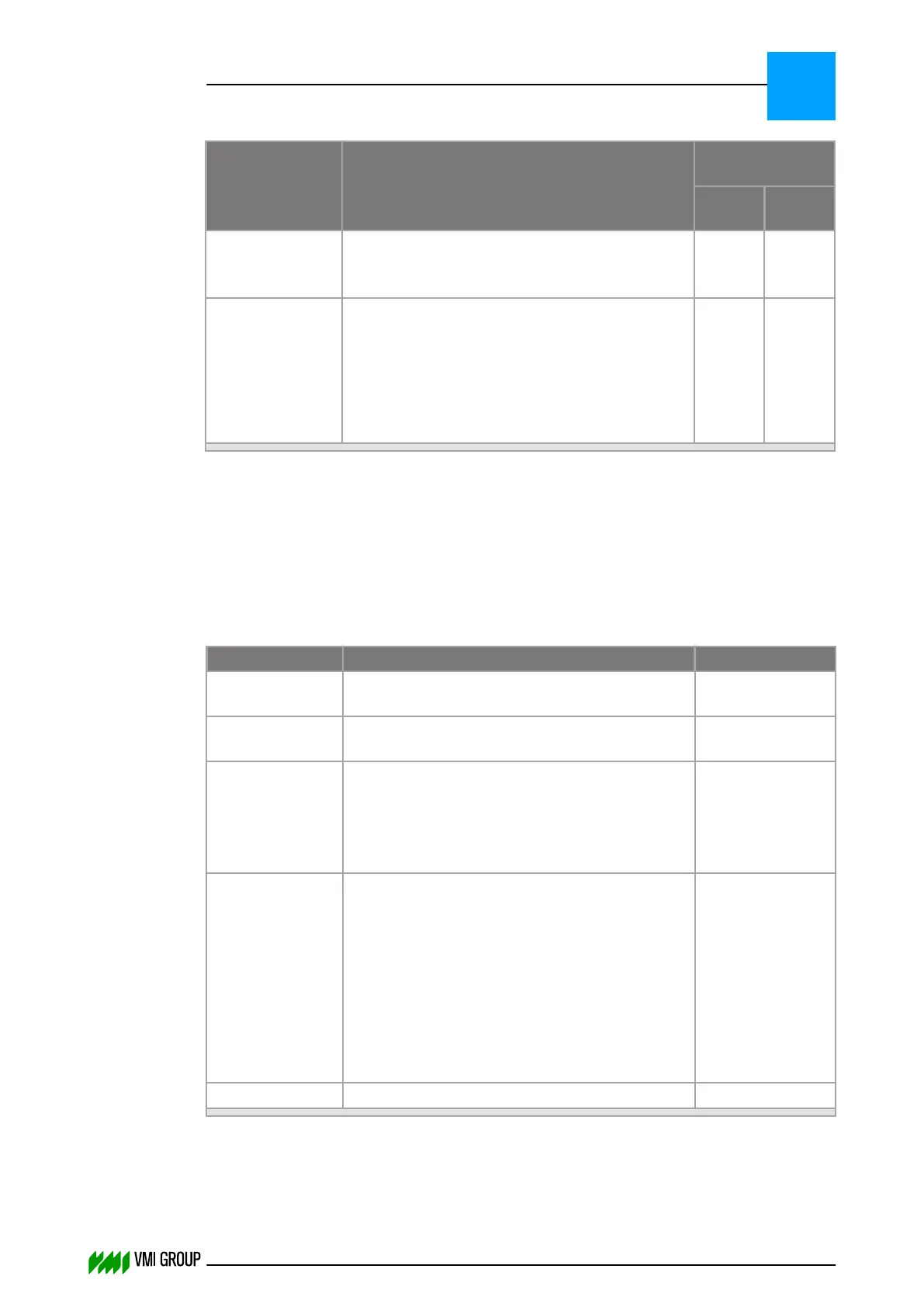

6.5.2 Default carcass system parameters

Parameter Description Value

Delay Material The time the material must be visible before it is

detected.

10 ms

Template Width The width of the template to calibrate a two

camera system.

xxxx mm

Width Offset The measured distance between the two

cameras calculated after calibration.

In general the value of this parameter is

calculated after the 'Sensor system' calibration

procedure.

xxxx mm

Delta Height The correction of width measurement for

differences in height of the material under the

camera.

This parameter is used to compensate for

differences in width measurement that are

caused by the fact that the material is passing

under the camera at a different height. The

camera system is sensitive to changes in the

vertical position of the material and this

parameter is used to compensate for the effect.

0 mm

Fault Percentage Fault percentage. 100 %

PARAMETERS

System parameters

6

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592

6-23

Loading...

Loading...