6.5.3 Default tread system parameters

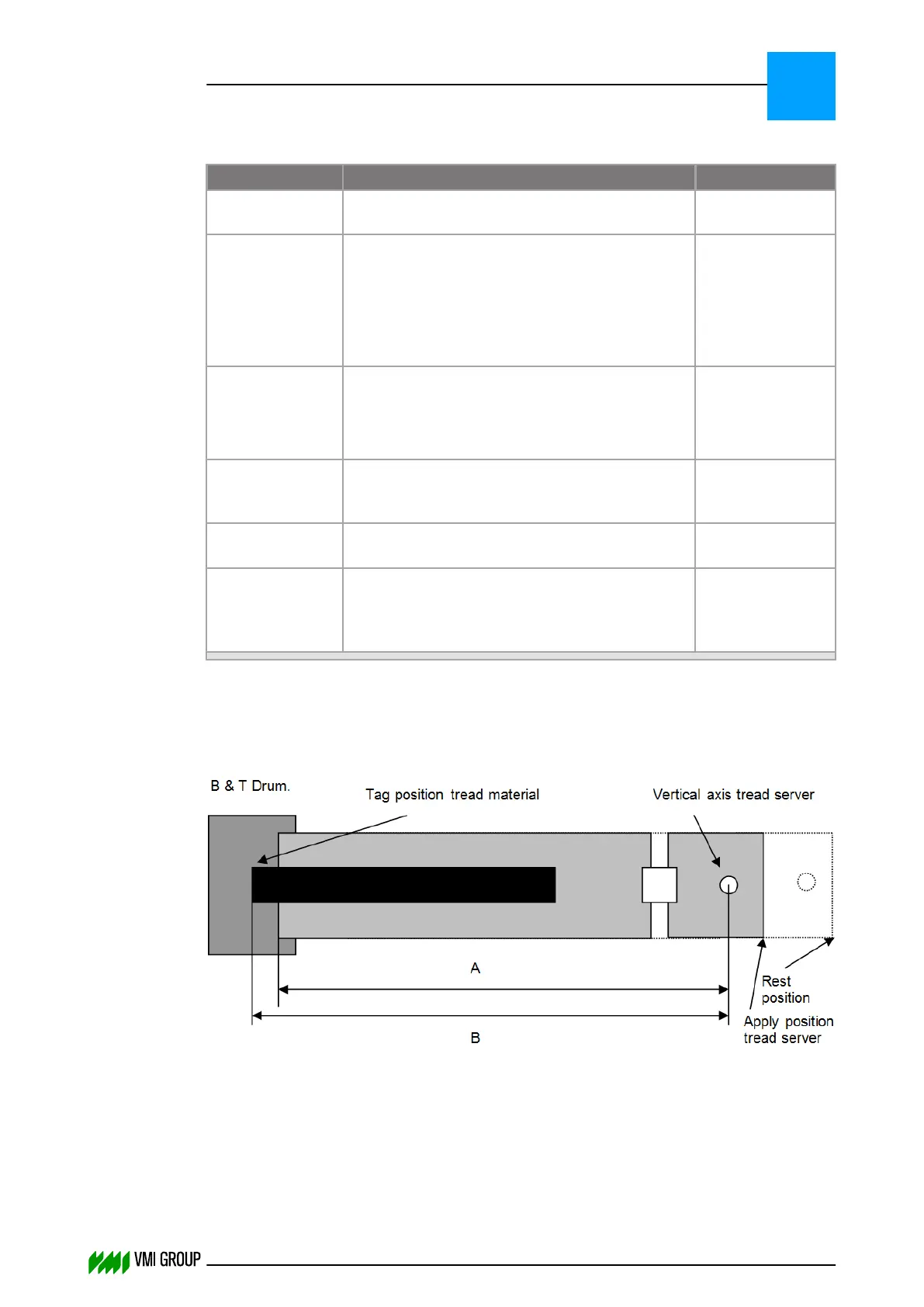

Parameter Description Value

Counts Per Meter The pulses per meter of the encoder.

Usually encoder calibration is started by the PLC.

xxxx mm

Mechanical Gain The quotient of distance pivot point to the center

of the B&T drum when tread conveyor is in apply

position and distance to the end of the conveyor

and the pivot point, times 1000.

Refer to How to measure the mechanical gain for

a tread server on page 6

‑

24.

X

(´1000)

Camera To

End Conveyor

distance

The distance between the camera and axis of the

conveyor belt turn.

Refer to How to measure the camera to end

conveyor distance on page 6

‑

25.

xxxx mm

Obstruction Width The size of the conveyor belt in the center of the

camera. Everything smaller than this threshold

will not be seen by the camera.

xxx mm

Template Width The calibration template width for 2 camera

system calibration.

xxxx mm

Width Offset The calibration offset camera to servicer.

Only applicable in 2 camera systems!

Difference between the center of the camera(s)

field of view and the drum.

0 mm

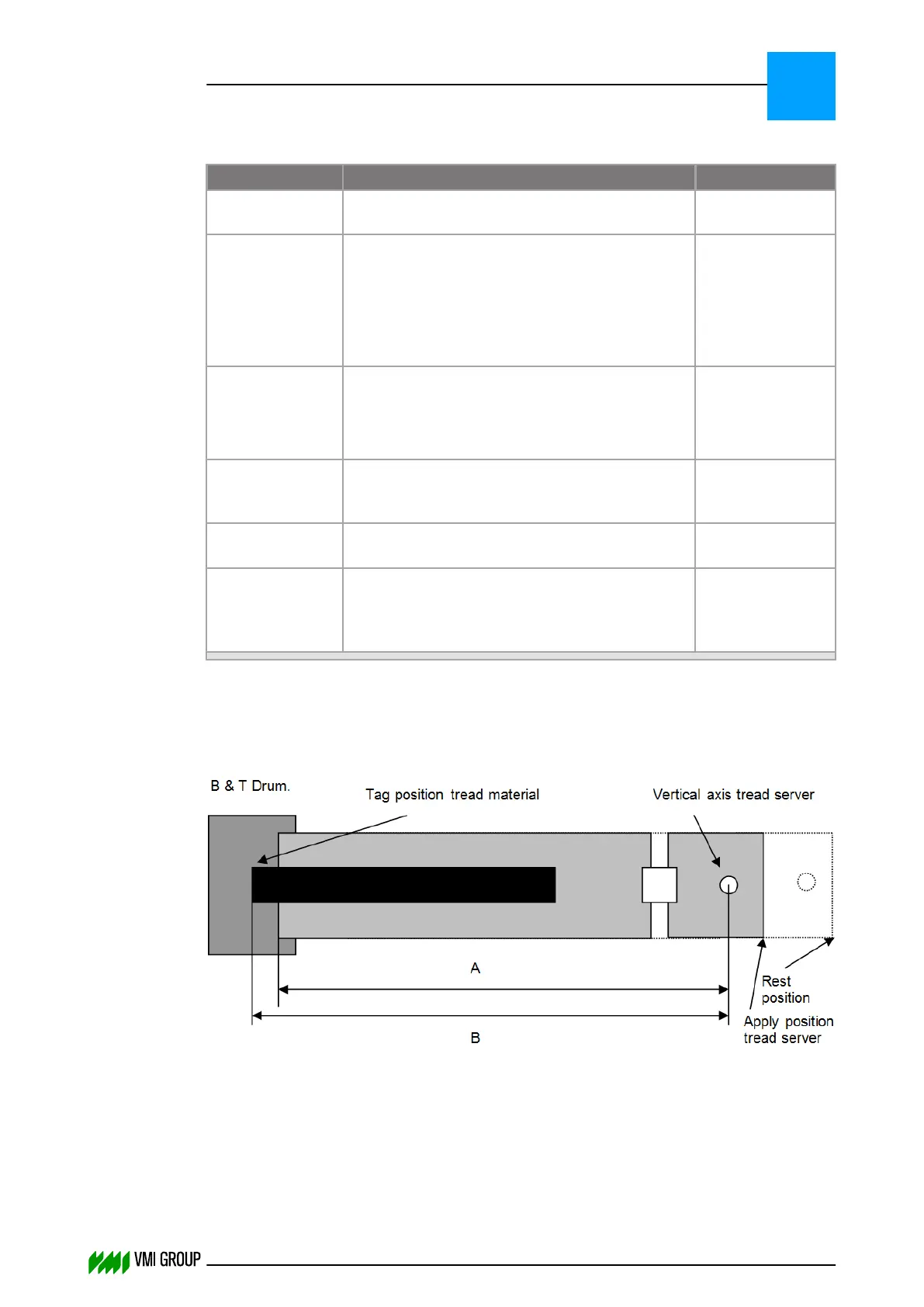

6.5.3.1 How to measure the mechanical gain for a tread server

The illustration shows the mechanical gain as the quotient of two measurements

(1000 x A/B).

PARAMETERS

System parameters

6

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592

6-24

Loading...

Loading...