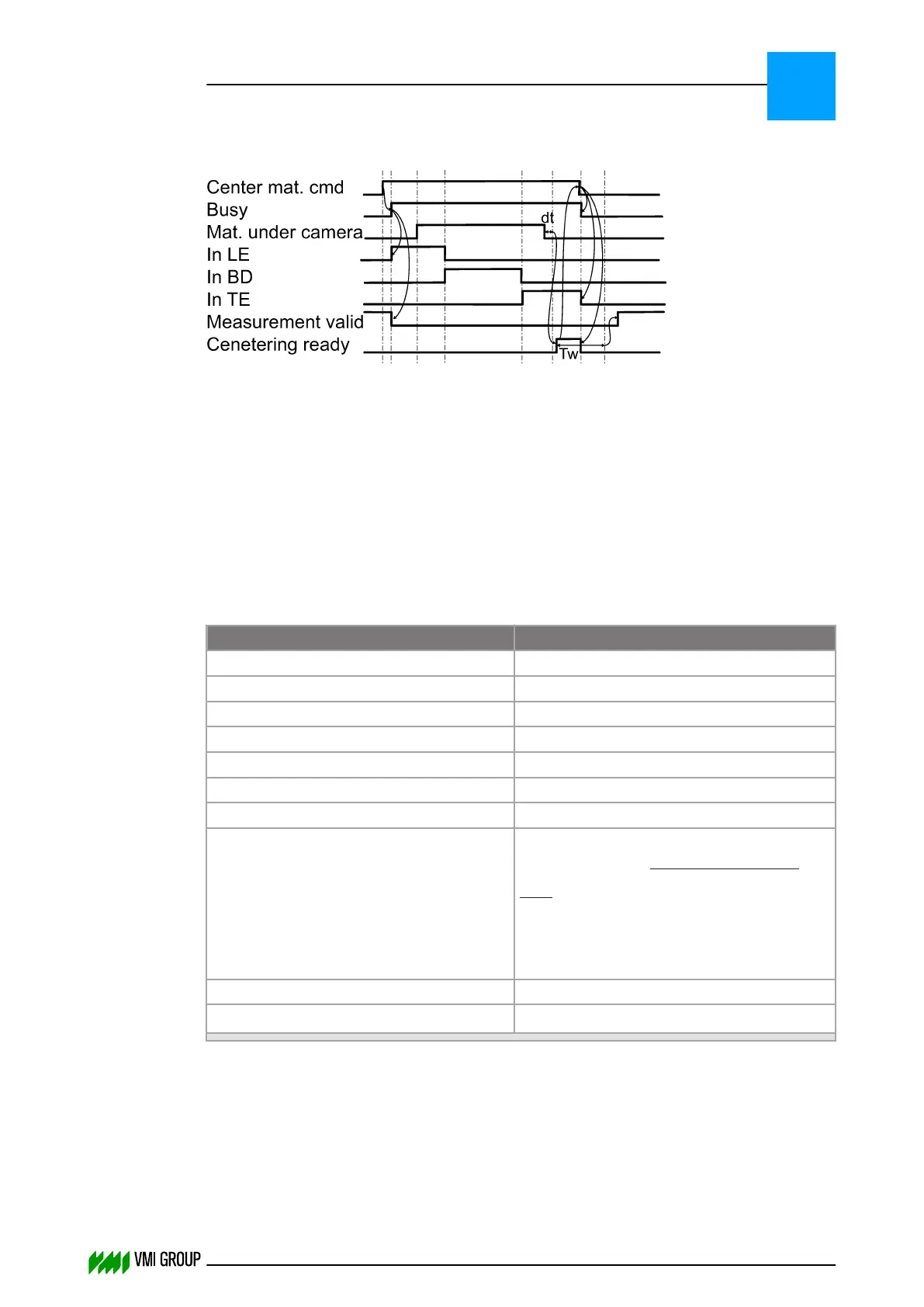

The diagram shows the PLC to VVSX handshake:

dt wait time to ignore material end faults.

Tw Time to write measurement results.

6.8.4 TREAD CENTERING command sequence

The Tread centering consists of two parts:

1. Tread read profile command sequence on page 6

‑

32

(the reading of the position of the entire tread)

2. Tread centering command sequence on page 6

‑

32

(the centering of the tread while it is applied on the B&T drum)

6.8.4.1 Tread read profile command sequence

PLC command VVS status

Read Profile Set(BusyTimer,1000 msec)

Busy

Busy AND Material under sensor

AND Hold

AND Holded

AND NOT Hold

AND NOT Holded

Centering material ready OR NOT Material

under sensor after more than 5 seconds!

Note Centering is ready when:

The scan material ready bit is raised OR the

material under sensor bit falls off because

material is removed manually from under the

camera.

Zero command

Zero status

1

1. ZERO STATUS is the situation where all bits, except the heartbeat bit, are set to zero.

PARAMETERS

Communication scenarios

6

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592

6-31

Loading...

Loading...