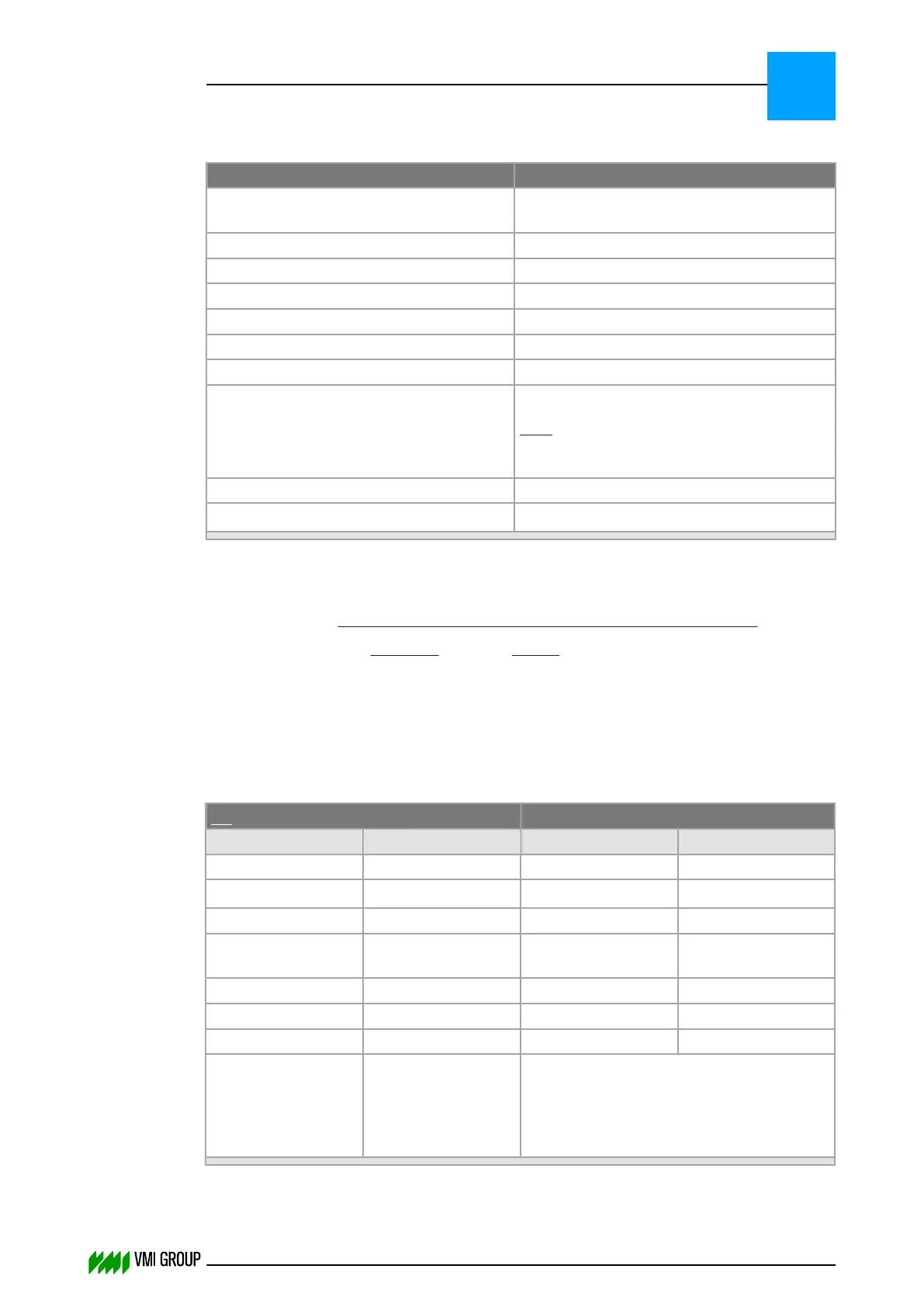

6.8.4.2 Tread centering command sequence

PLC command VVS status

Center material Set(BusyTimer,1000

msec)

Busy

Busy AND Material under sensor

AND Hold

AND Holded

AND NOT Hold

AND NOT Holded

Centering material ready

Note Centering is ready when:

The recorded profile was read back to the

end.

Zero command

Zero status

1

1. ZERO STATUS is the situation where all bits, except the heartbeat bit, are set to zero.

IF Timeout(BusyTimer) THEN

HMI should display error message "VVS did not start conveyor centering"

Operator should press the RESTART button

Zero command

Restart the TREAD CENTRING command sequence

END IF

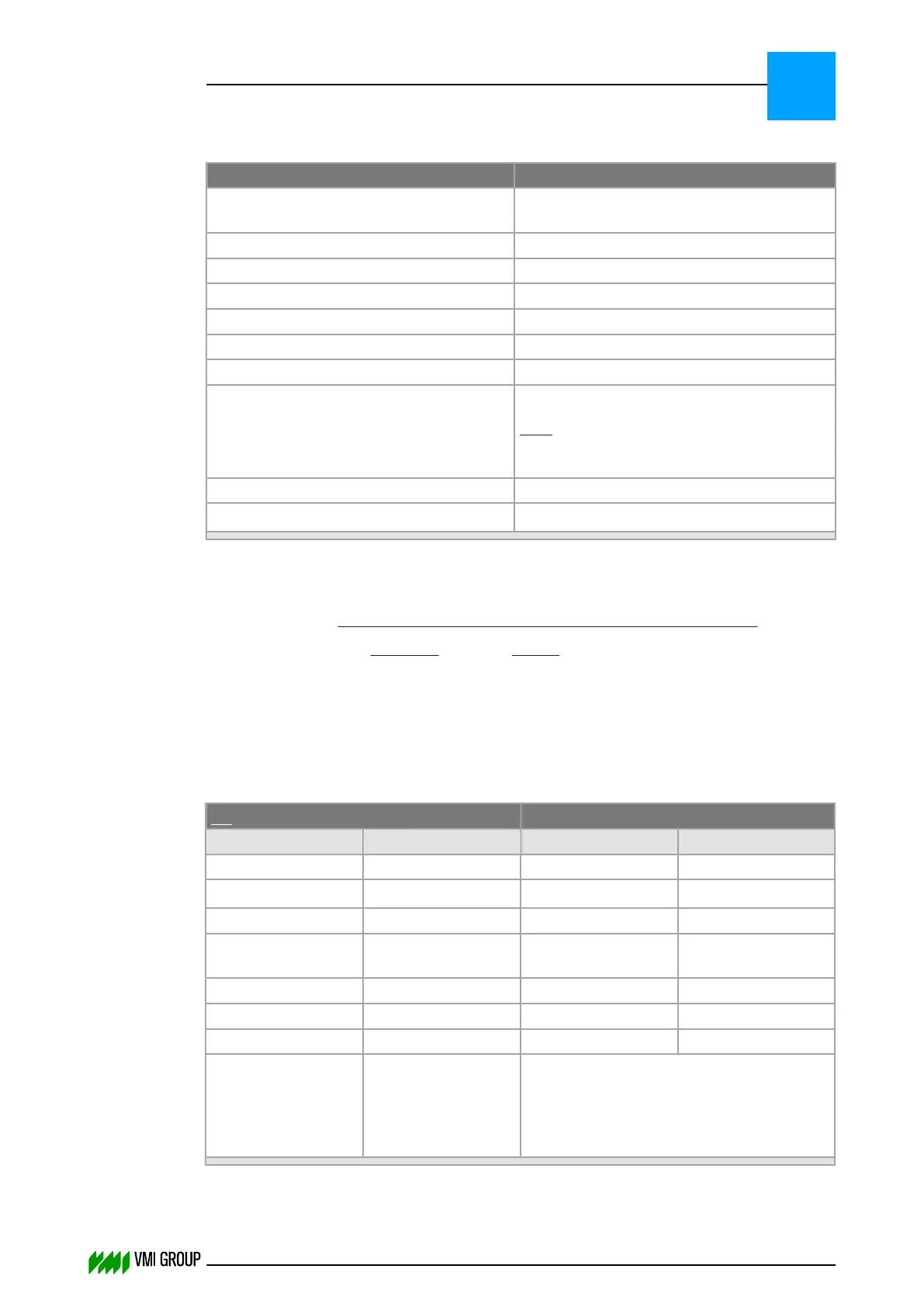

6.8.5 EMERGENCY STOP recovery sequence

No material under sensor Material under sensor

PLC Command VVS Status PLC Command VVS Status

Send parameters Send parameters

Home conveyor

Hold

1

Busy Busy AND Holded

Busy AND Home

conveyor ready

Center material AND

Hold

Zero command Busy AND Holded

Zero status Center material

Busy

Be sure never to send a zero command

after an E-STOP while material is under

the sensor. Instead raise the HOLD bit

and continue centering after having

cleared the HOLD bit.

PARAMETERS

Communication scenarios

6

THINKING FORWARD

VMI Vision System VVS (OL82) VVSX 13.0.12.0, VVSU 3.0.6 / 4 / 2016-07-11 / pd#175592

6-32

Loading...

Loading...