The PCB layout and power system design meet the recommended criteria described in the

UltraScale Architecture PCB Design User Guide (UG583).

RECOMMENDED: To ensure reliable operaon, Xilinx recommends running the

report_power

command in

the Vivado tools for designs targeng this board. The reported rail current requirements must not exceed the

values listed in the following table.

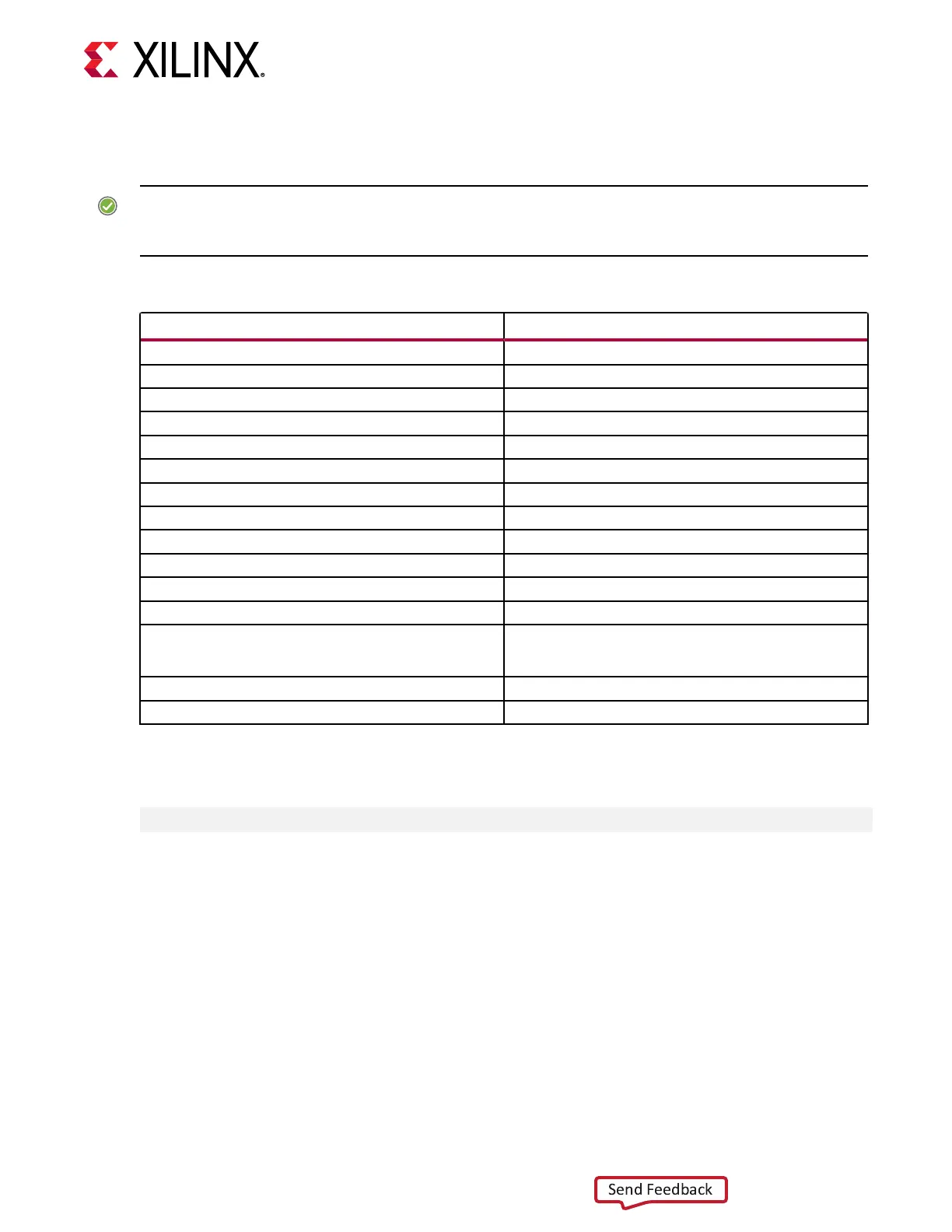

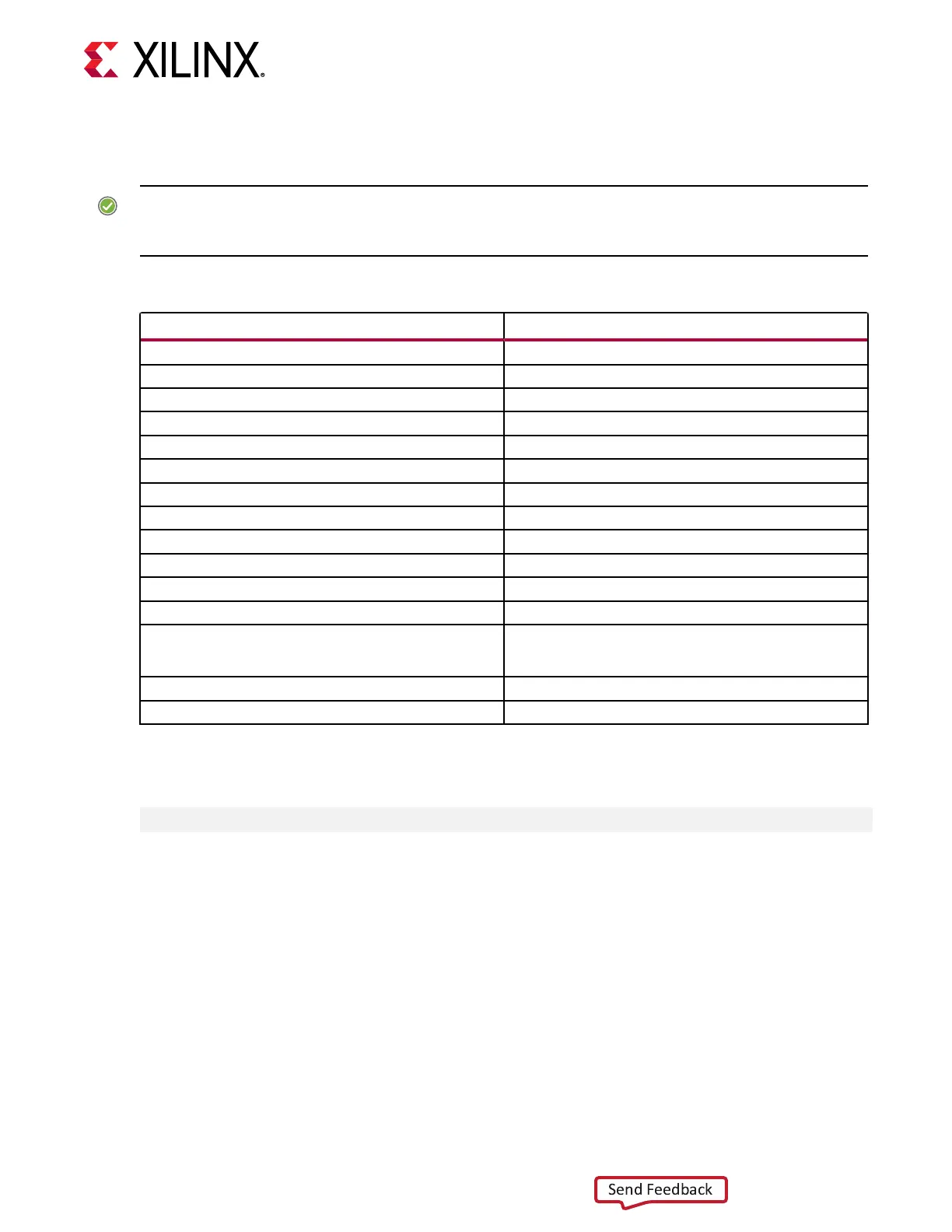

Table 26: Device Rail Maximum Current

Device Rail Maximum Current (Amps)

V

CCINT

60

V

CCINT_IO

+ V

CCBRAM

+ V

CC_PSINTLP

+ V

CC_PSINTFP

+ V

CC_PSINTFP_DDR

18

MGTYV

CCAUX

+ V

PS_MGTRAVTT

0.5

MGTYA

VCC

4

V

PS_MGTRAVCC

0.5

MGTYA

VTT

+ V

CC_PSPLL

7

V

CCINT_AMS

28

V

ADC_AVCC

4

V

ADC_AVCCAUX

2

V

DAC_AVCC

6

V

DAC_AVCCAUX

1.5

V

DAC_AVTT

1.5

V

CCAUX

+ V

CCAUX_IO

+ V

CCO

1.8V + V

CCAUX_IO

+ V

CC_PSAUX

+

V

CC_PSDDR_PLL

+ V

CCO_PSIO0_500

+ V

CCO_PSIO1_501

+ V

CCO_PSIO2_502

+

V

CCO_PSIO3_503

+ V

CCADC

+ V

CC_PSADC

8

V

CCO

1.2V + V

CCO_PSDDR_504

6

V

CCO

#V (# corresponds to VADJ programmed voltage) 6

The total device power must remain under 50W. To assist the Vivado tools in reporng when

power exceeds this amount, add this XDC constraint:

set_operating_conditions -design_power_budget 50 ;# (50W max power)

Monitoring Voltage and Current

Voltage and current monitoring and control are available for the Inneon power system

controllers through the Inneon PowIRCenter graphical user interface. The PMBus interface

controllers and regulators are accessed through 1x3 PMBus connector J21, that is provided for

use with the Inneon PowIRCenter USB cable (Inneon part number USB005) and can be

ordered from the Inneon Integrated Circuits website. The associated Inneon PowerTool GUI

can be downloaded from the Inneon website. This is the simplest and most convenient way to

monitor the voltage and current values for the Inneon PMBus programmed power rails listed in

Table 25.

Chapter 3: Board Component Descriptions

UG1390 (v1.1) July 10, 2020 www.xilinx.com

ZCU216 Board User Guide 66

Loading...

Loading...