6F65G11

5-28

9

8

7

6

5

4

3

2

1

Crankcase

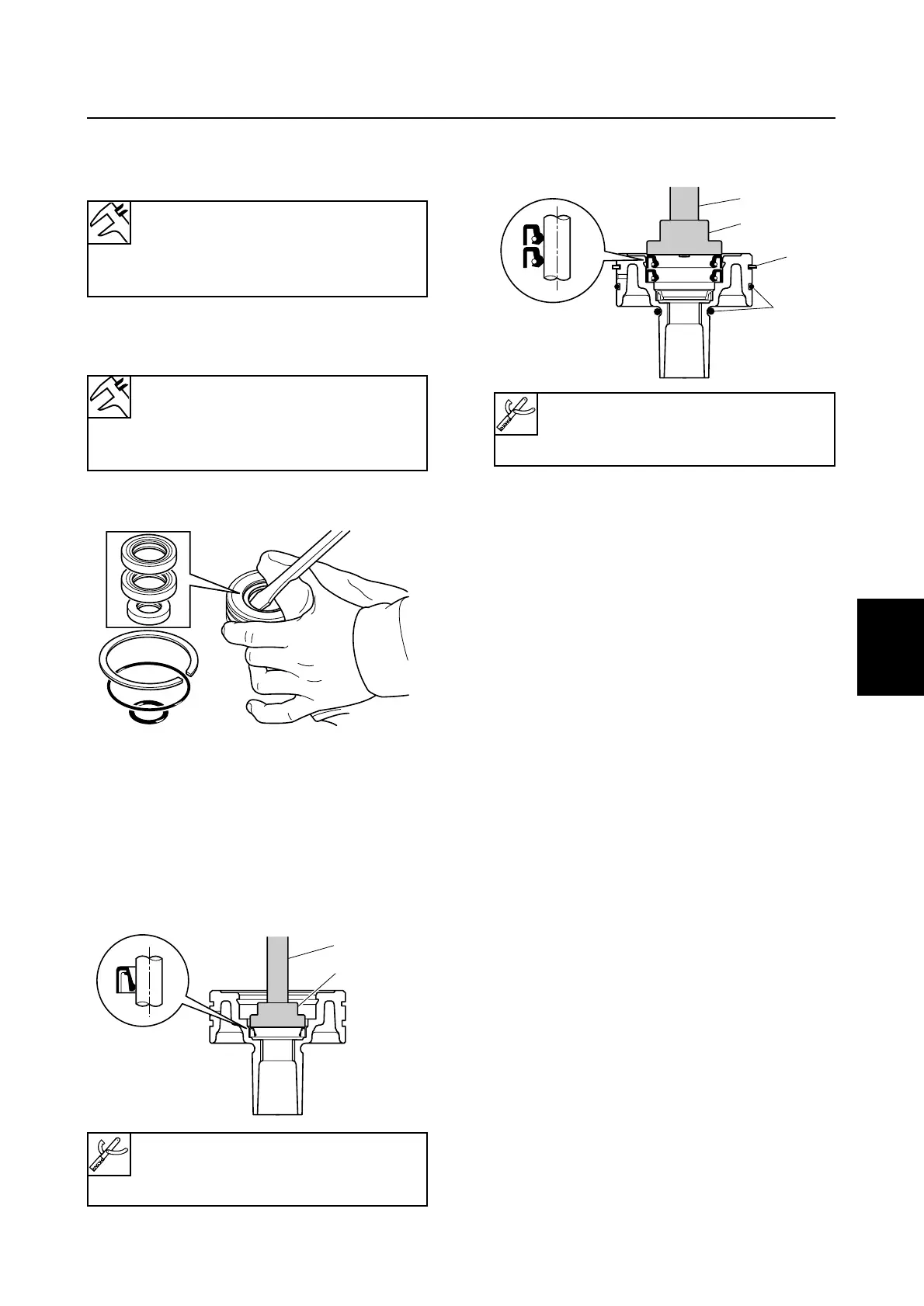

2. Apply grease to new oil seals, then install

them into the oil seal housing.

3. Install the circlip 5, apply grease to new

O-rings 6, and then install them.

Disassembling the piston

1. Remove the clips with pliers, and then

remove the piston pin.

2. Separate the piston from the connecting

rod.

3. Remove the bearing and washers at the

connecting rod small end.

4. Remove the top ring and 2nd piston ring.

2. Calculate the taper limit. Replace or

rebore the cylinder block if above specifi-

cation.

3. Calculate the out-of-round limit. Replace

or rebore the cylinder block if above

specification.

Disassembling the oil seal housing

1. Remove the O-ring and oil seals.

Checking the oil seal housing

1. Check the oil seal housing for cracks,

damage, or corrosion. Replace if neces-

sary.

Assembling the oil seal housing

1. Apply grease to new oil seals, then install

them into the oil seal housing.

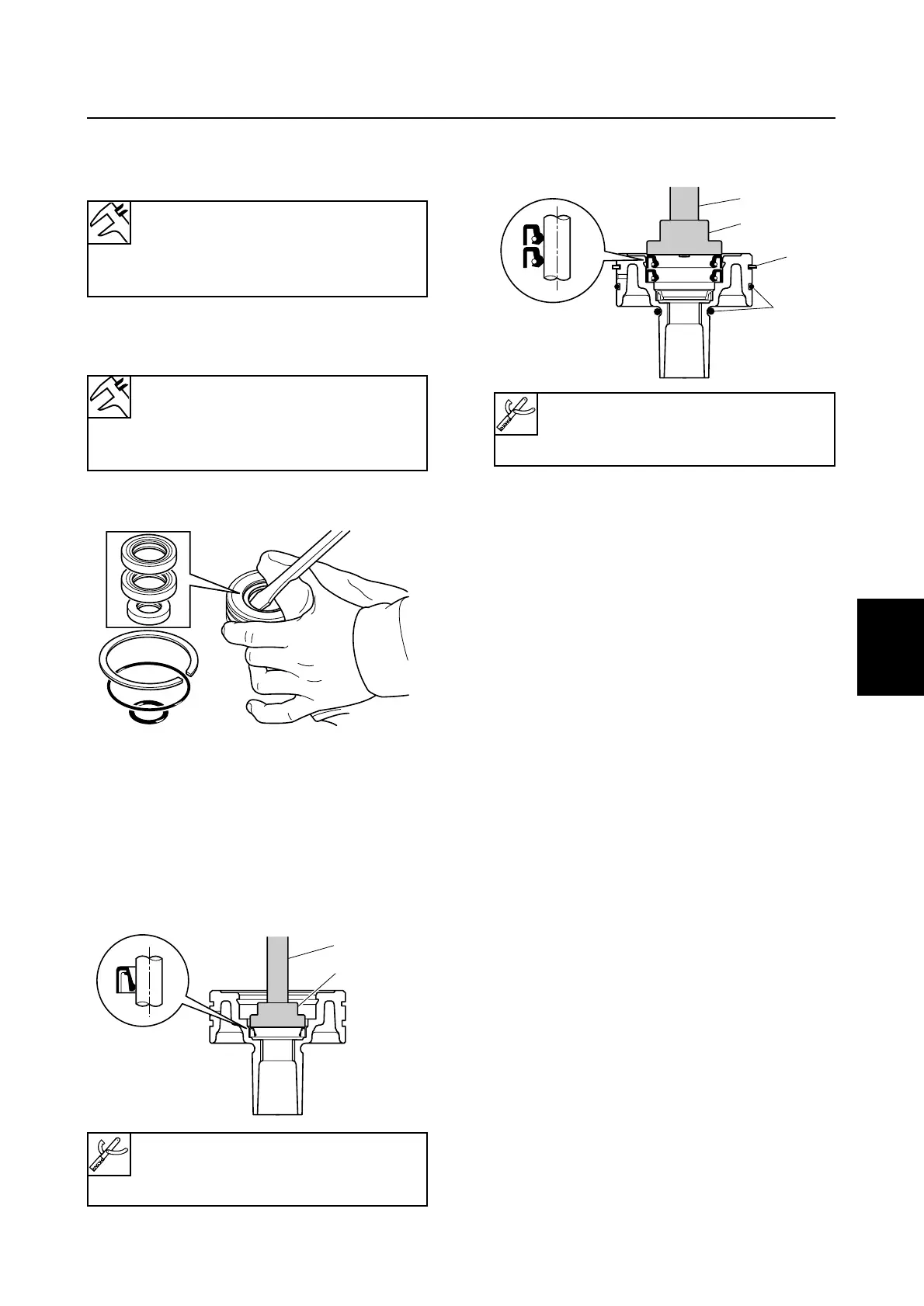

Needle bearing attachment 1:

90890-06613

Driver rod L3 2:90890-06652

Needle bearing attachment 3:

90890-06631

Driver rod LS 4:90890-06606

Loading...

Loading...