6F65G11

5-32

9

8

7

6

5

4

3

2

1

Crankcase

8. Using the bearing separator to slightly

move the inner race off the shaft, and

then remove the inner race.

NOTE:

Use care not to scratch the shaft.

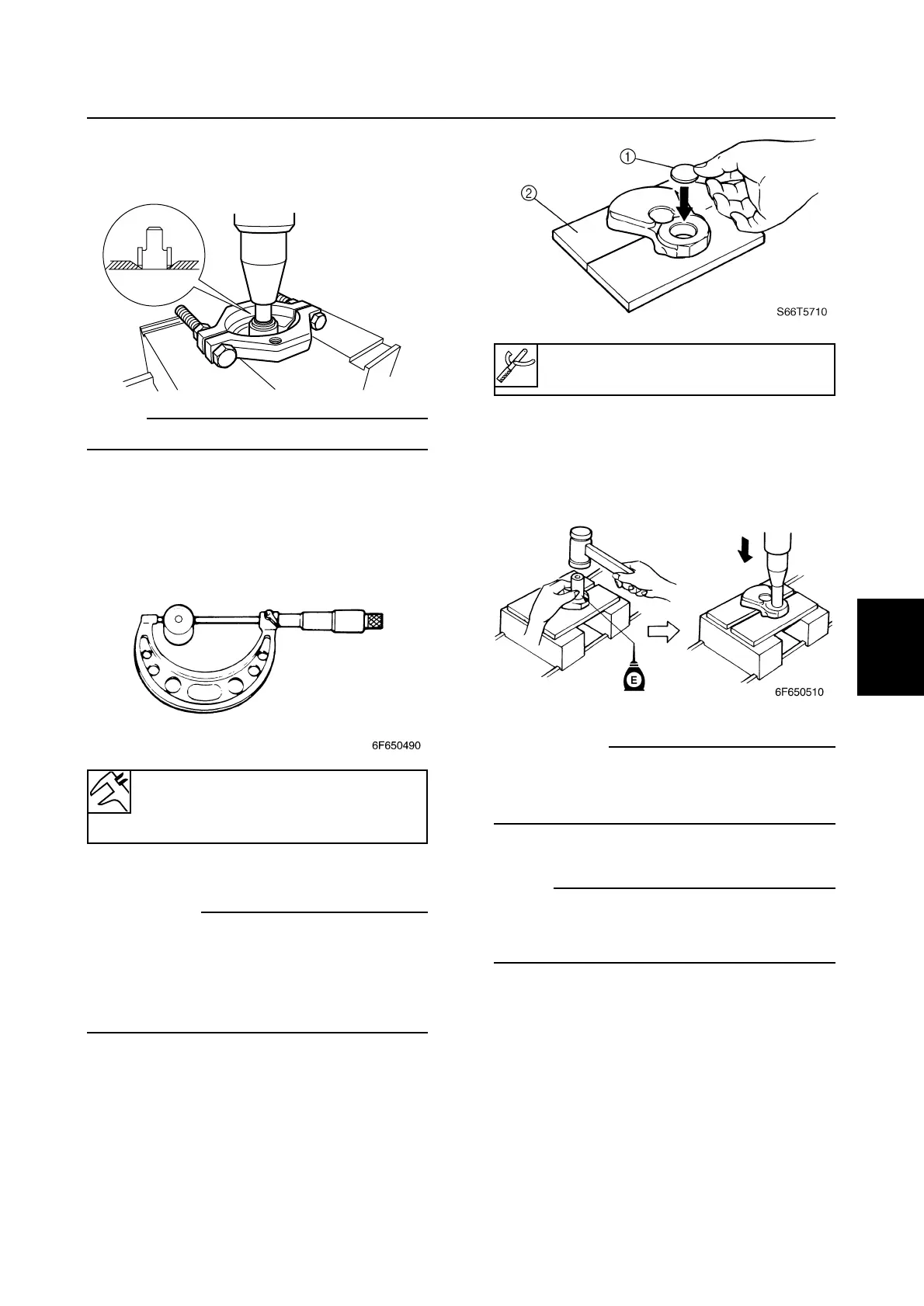

Checking the crankpin

1. Measure the crankpin diameter. Replace

if out of specification.

Assembling the crankshaft

cC

9 When reassembling the crankshaft,

wash all component parts in clean

kerosene (do not use gasoline).

9 Do not reuse bearings, always replace

them with new ones.

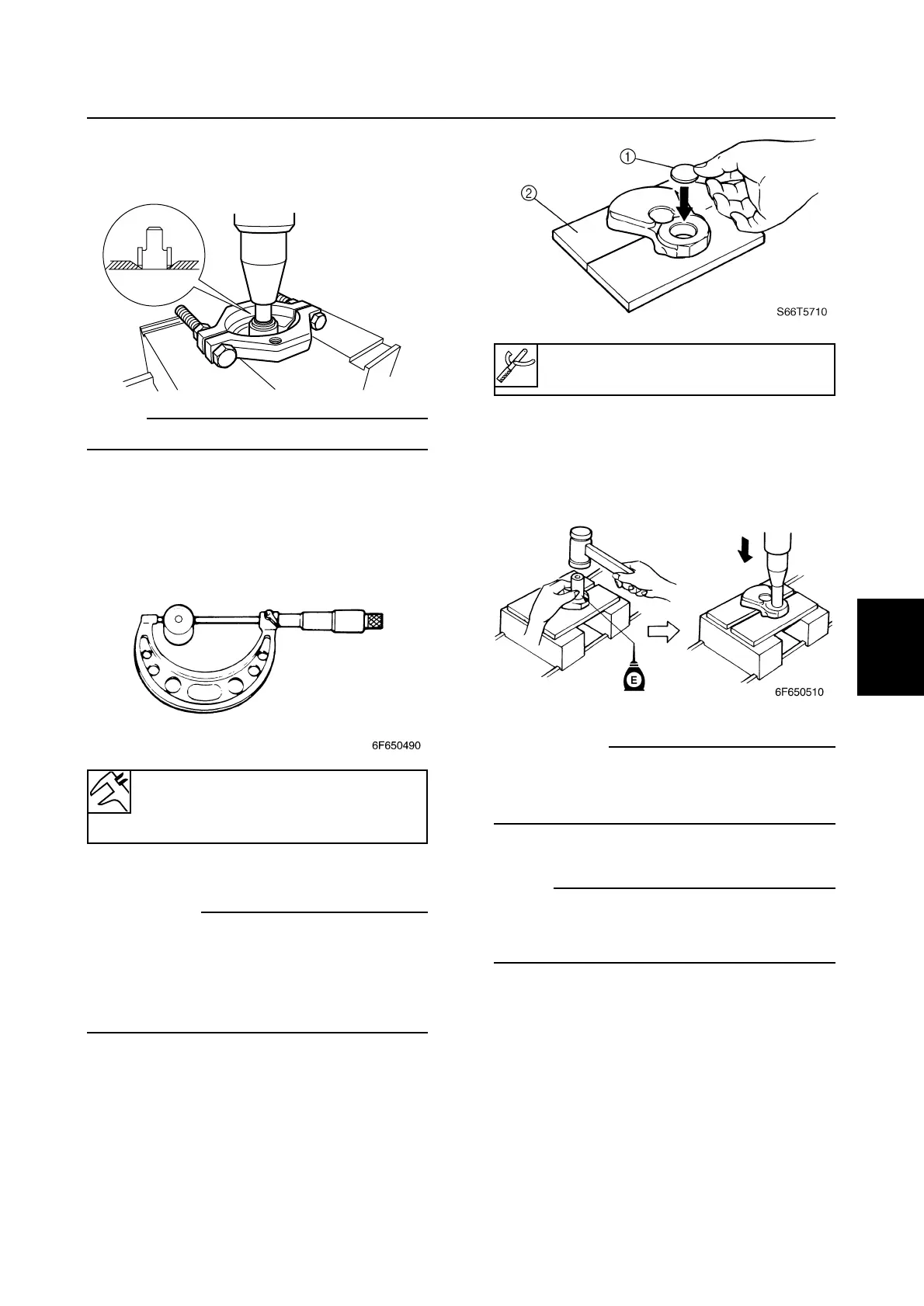

1. Insert spacer C 1 into the crankpin hole

of crank 2 (or crank 4).

2. Apply engine oil to the crankpin and

insert it into the crankpin hole by tapping

it with a copper hammer, and then install

the crankpin using a press.

cC

9 Take care so that the crank pin is set

squarely into the crank web.

9 Do not apply force in excess of 5 tons.

NOTE:

Follow the same procedure for both crank 2

and crank 4 to install the crankpins using a

press.

Loading...

Loading...