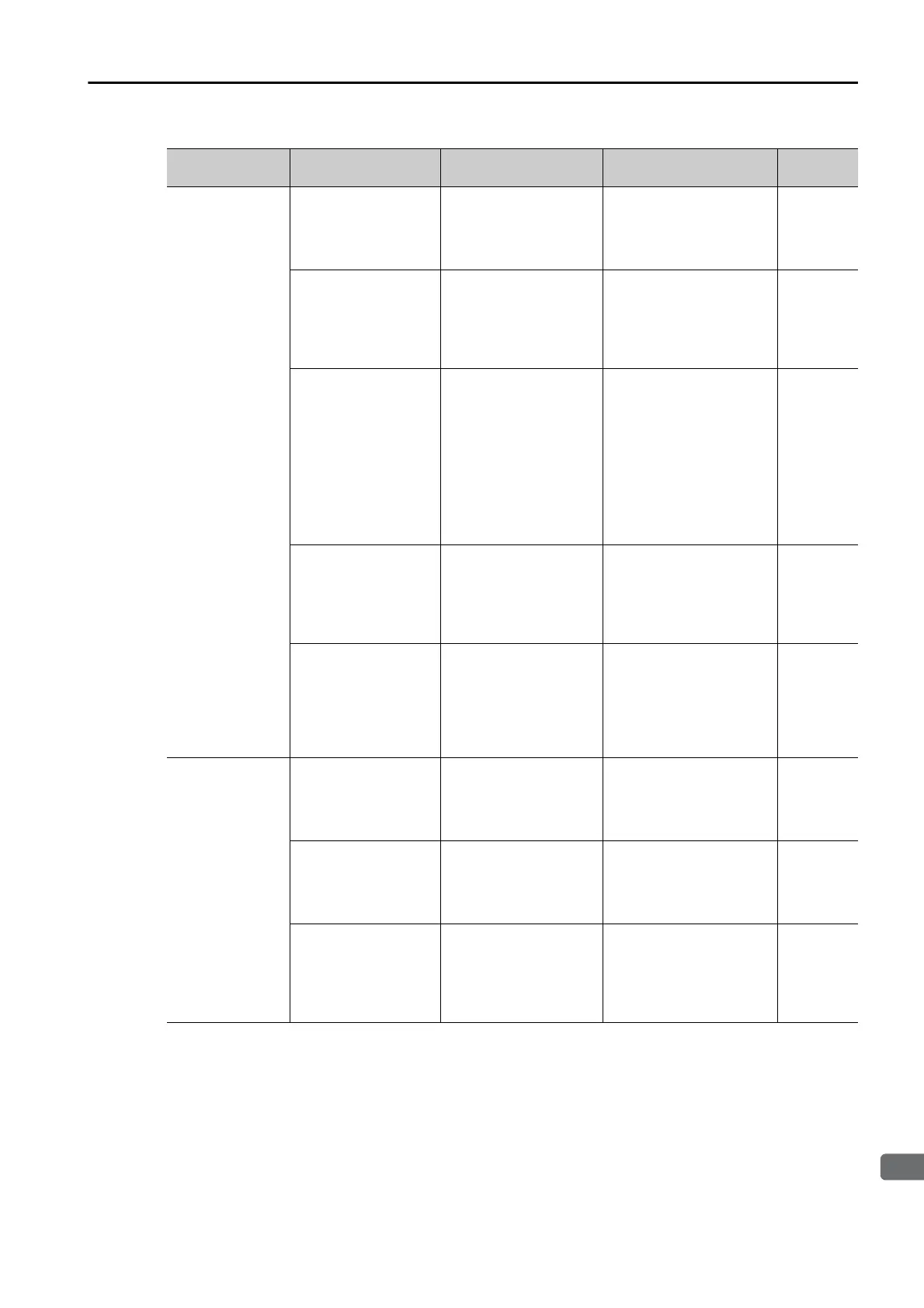

6.1 Alarm Displays

6.1.2 Troubleshooting Alarms

6-27

A.C90:

Encoder Commu-

nications Error

There is a faulty con-

tact in the connector

or the connector is

not wired correctly for

the encoder.

Check the condition of

the encoder connector.

Reconnect the encoder

connector and check the

encoder wiring.

*1

There is a cable dis-

connection or short-

circuit in the encoder.

Or, the cable imped-

ance is outside the

specified values.

Check the condition of

the Encoder Cable.

Use the Encoder Cable

within the specified speci-

fications.

–

One of the following

has occurred: corro-

sion caused by

improper tempera-

ture, humidity, or gas,

a short-circuit caused

by entry of water

drops or cutting oil, or

faulty contact in con-

nector caused by

vibration.

Check the operating

environment.

Improve the operating

environment, and replace

the cable. If the alarm still

occurs, replace the SER-

VOPACK.

*1

A malfunction was

caused by noise.

–

Correct the wiring around

the encoder by separating

the Encoder Cable from

the Servomotor Main Cir-

cuit Cable or by ground-

ing the encoder.

*1

A failure occurred in

the SERVOPACK.

–

Connect the Servomotor

to another SERVOPACK,

and turn ON the control

power supply. If no alarm

occurs, the SERVOPACK

may be faulty. Replace the

SERVOPACK.

–

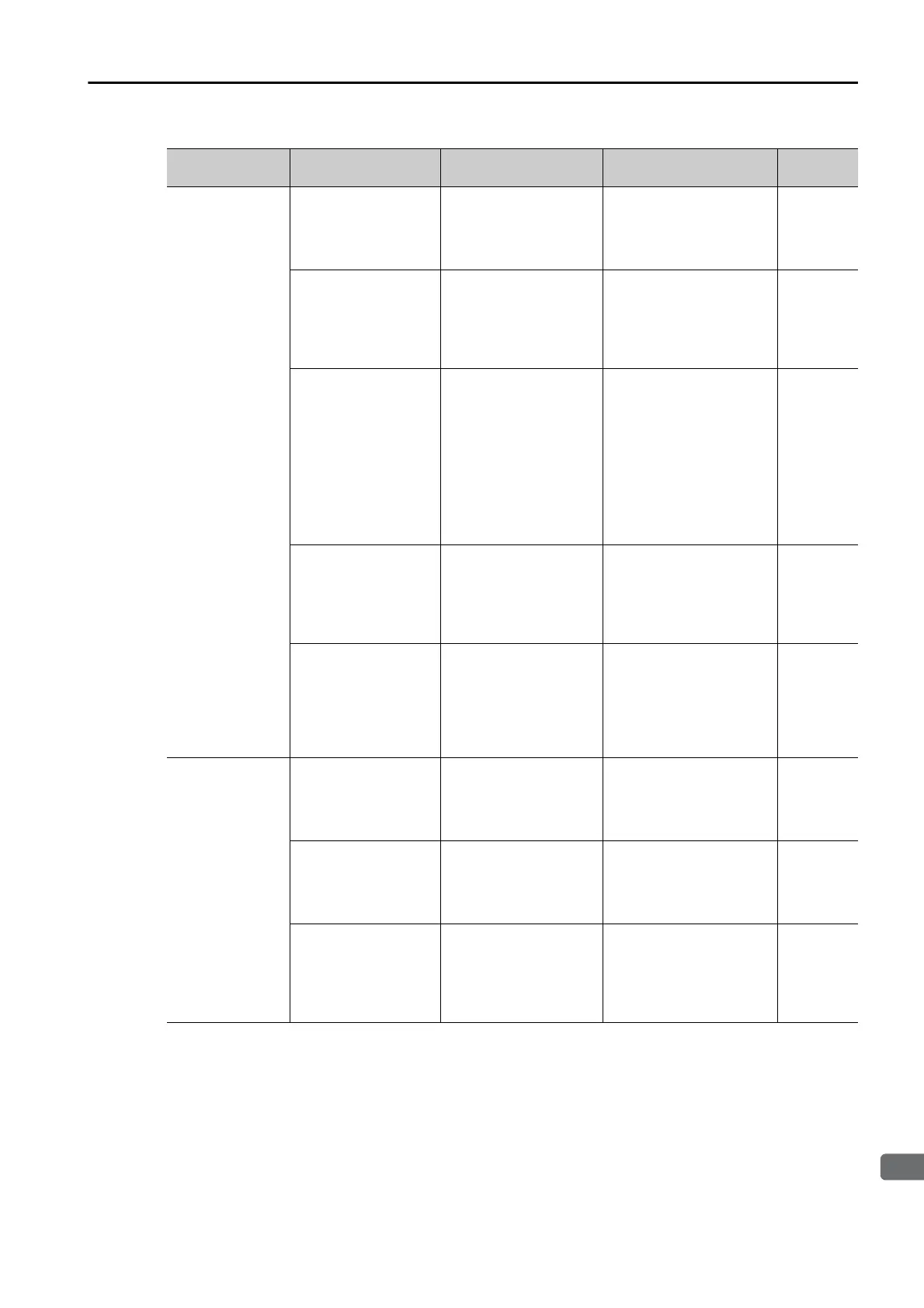

A.C91:

Encoder Commu-

nications Posi-

tion Data

Acceleration Rate

Error

Noise entered on the

signal lines because

the Encoder Cable is

bent or the sheath is

damaged.

Check the condition of

the Encoder Cable and

connectors.

Check the Encoder Cable

to see if it is installed cor-

rectly.

*1

The Encoder Cable is

bundled with a high-

current line or

installed near a high-

current line.

Check the installation

condition of the

Encoder Cable.

Confirm that there is no

surge voltage on the

Encoder Cable.

–

There is variation in

the FG potential

because of the influ-

ence of machines on

the Servomotor side,

such as a welder.

Check the installation

condition of the

Encoder Cable.

Properly ground the

machine to separate it

from the FG of the

encoder.

–

Continued on next page.

Continued from previous page.

Alarm Number:

Alarm Name

Possible Cause Confirmation Correction Reference

Loading...

Loading...