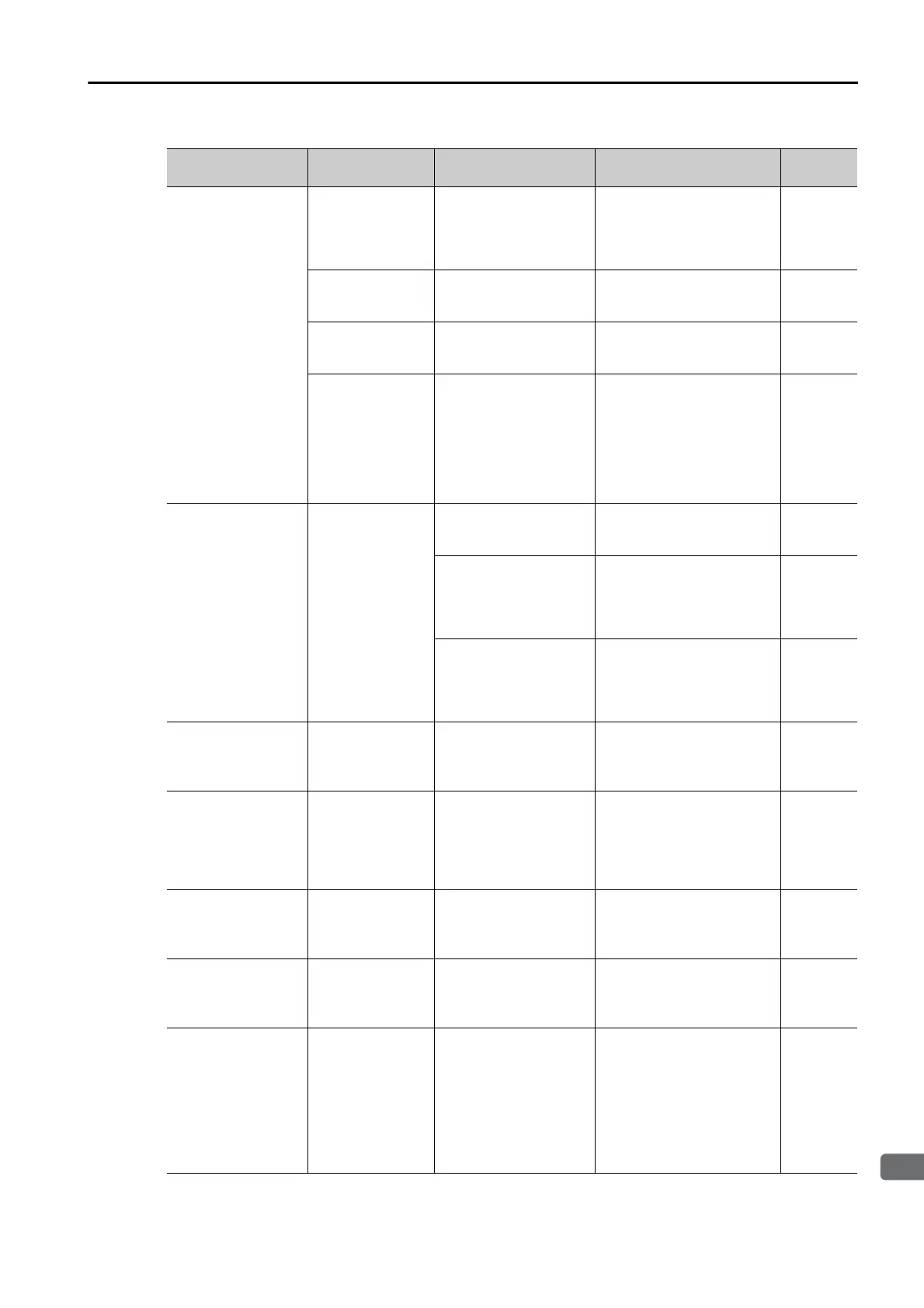

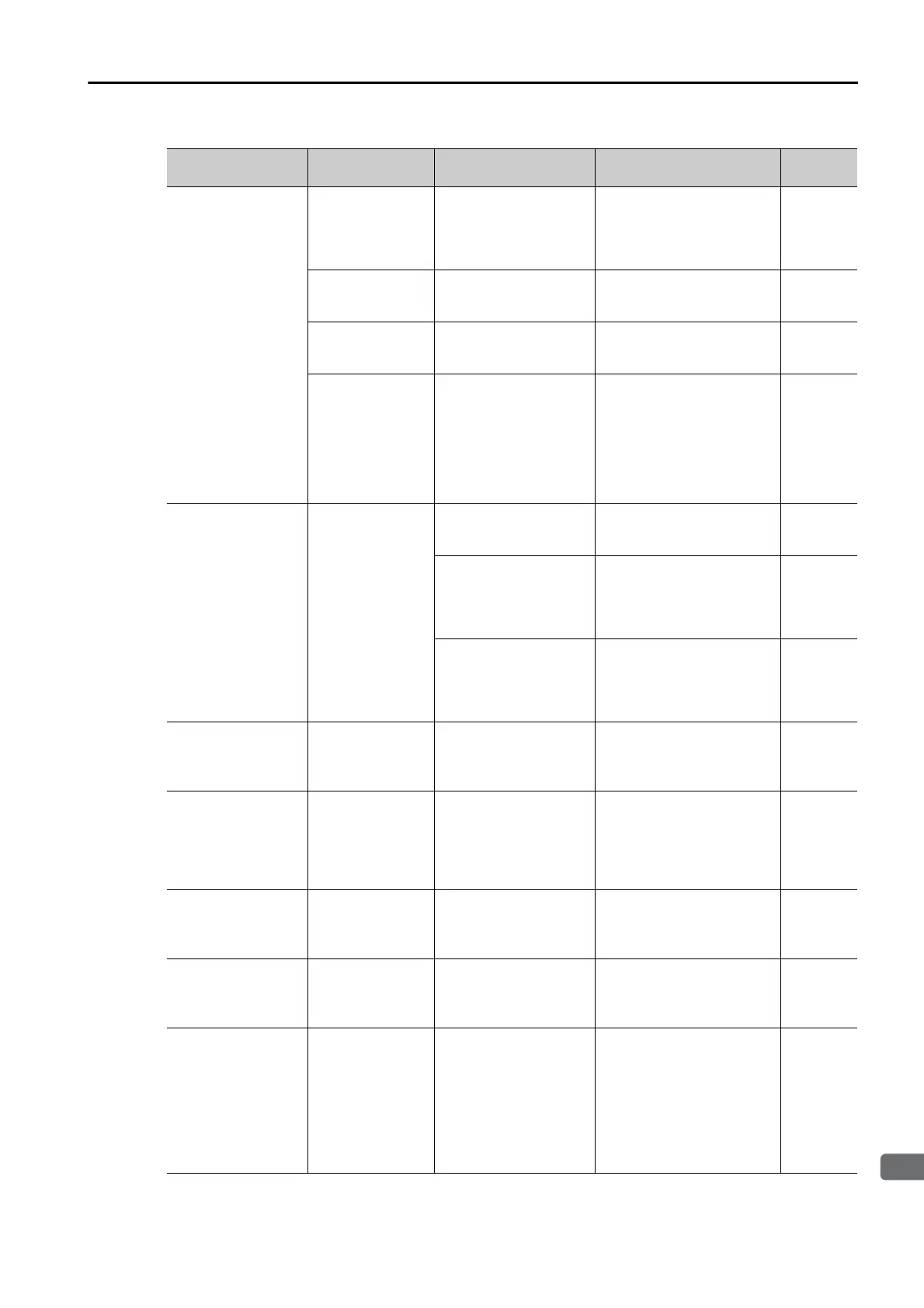

6.2 Warning Displays

6.2.2 Troubleshooting Warnings

6-43

A.93B:

Overheat Warning

The surrounding

temperature is too

high.

Check the surrounding

temperature using a

thermometer.

Lower the surrounding tem-

perature by improving the

installation conditions of the

Linear Servomotor or the

machine.

–

Operation was

performed under

an excessive load.

Use the accumulated

load ratio to check the

load during operation.

Reconsider the load and

operating conditions.

–

A failure occurred

in the SERVO-

PACK.

–

The SERVOPACK may be

faulty. Replace the SERVO-

PACK.

–

The temperature

detection circuit in

the Linear Servo-

motor is faulty or

the sensor

attached to the

machine is faulty.

–

The temperature detection

circuit in the Linear Servo-

motor may be faulty or the

sensor attached to the

machine may be faulty.

Replace the Linear Servo-

motor or repair the sensor

attached to the machine.

–

A.942:

Speed Ripple Com-

pensation Informa-

tion Disagreement

The speed ripple

compensation

information stored

in the encoder

does not agree

with the speed

ripple compensa-

tion information

stored in the

SERVOPACK.

–

Reset the speed ripple

compensation value on the

SigmaWin+.

*

–

Set Pn423 to n.1 (Do

not detect A.942 alarms).

However, changing the set-

ting may increase the speed

ripple.

*

–

Set Pn423 to n.0

(Disable speed ripple com-

pensation). However,

changing the setting may

increase the speed ripple.

*

A.94A:

Data Setting Warn-

ing 1 (Parameter

Number Error)

An invalid param-

eter number was

used.

Check the command

that caused the warn-

ing.

Use the correct parameter

number.

*

A.94b:

Data Setting Warn-

ing 2 (Out of Range)

The set com-

mand data was

clamped to the

minimum or maxi-

mum value of the

setting range.

Check the command

that caused the warn-

ing.

Set the parameter within

the setting range.

*

A.94C:

Data Setting Warn-

ing 3 (Calculation

Error)

The calculation

result of the set-

ting is not correct.

Check the command

that caused the warn-

ing.

Set the parameter within

the setting range.

*

A.94d:

Data Setting Warn-

ing 4 (Parameter

Size)

The parameter

size set in the

command is not

correct.

Check the command

that caused the warn-

ing.

Set the correct parameter

size.

*

A.94E:

Data Setting Warn-

ing 5 (Latch Mode

Error)

A latch mode error

was detected.

Check the command

that caused the warn-

ing.

Change the setting of

Pn850 or the LT_MOD data

for the LTMOD_ON com-

mand sent by the host con-

troller to an appropriate

value.

(This applies when using

the MECHATROLINK-II-

compatible profile.)

*

Continued on next page.

Continued from previous page.

Warning Number:

Warning Name

Possible Cause Confirmation Correction Reference

Loading...

Loading...