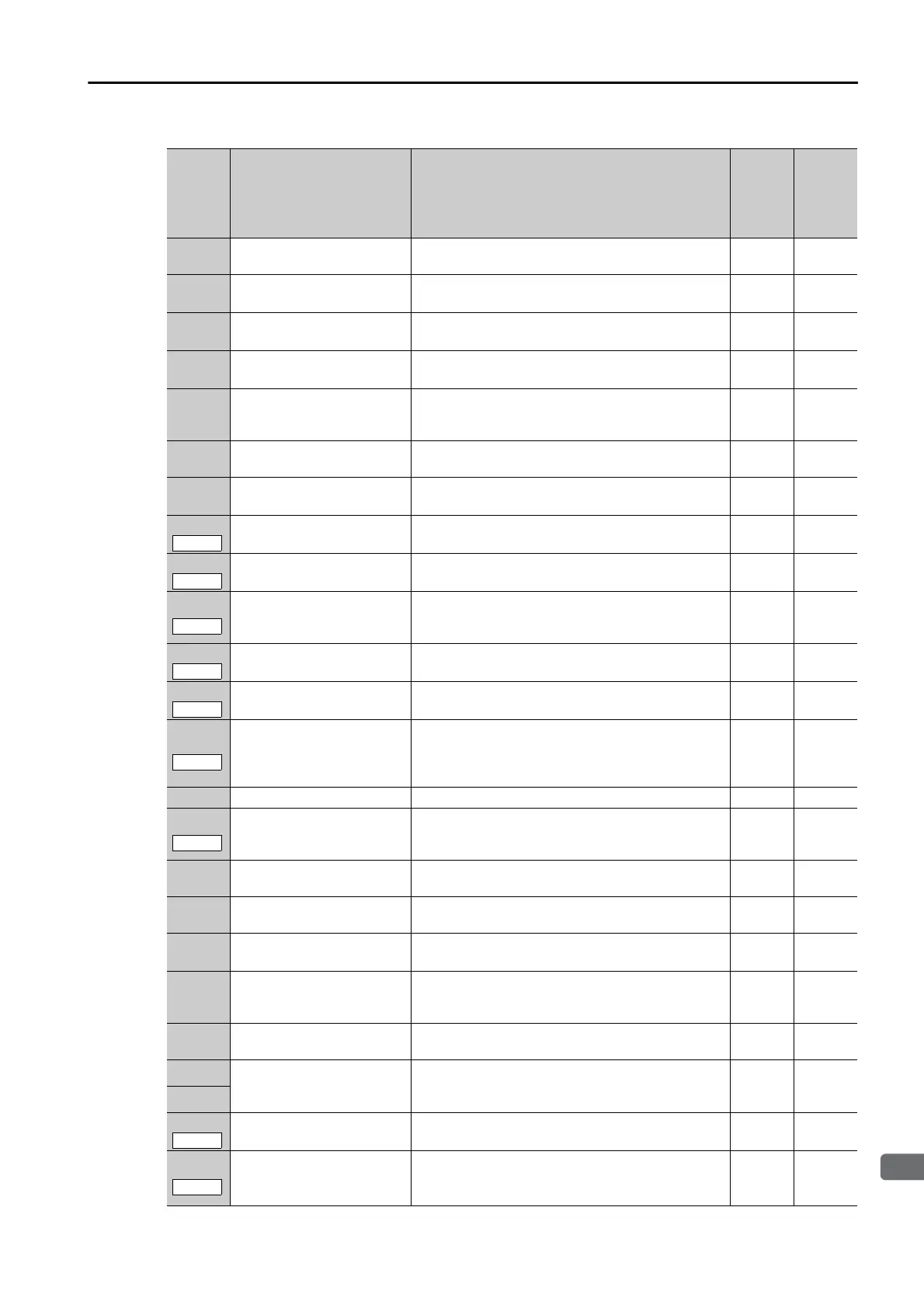

6.1 Alarm Displays

6.1.1 List of Alarms

6-3

A.050 Combination Error

The capacities of the SERVOPACK and Servomo-

tor do not match.

Gr.1 Yes

A.051

Unsupported Device

Alarm

An unsupported device was connected. Gr.1 No

A.070

Motor Type Change

Detected

The connected motor is a different type of motor

from the previously connected motor.

Gr.1 No

A.080

Linear Encoder Pitch

Setting Error

The setting of Pn282 (Linear Encoder Scale Pitch)

has not been changed from the default setting.

Gr.1 No

A.0b0

Invalid Servo ON

Command Alarm

The SV_ON (Servo ON) command was sent from

the host controller after a utility function that turns

ON the Servomotor was executed.

Gr.1 Yes

A.100 Overcurrent Detected

An overcurrent flowed through the power transis-

tor or the heat sink overheated.

Gr.1 No

A.101

Motor Overcurrent

Detected

The current to the motor exceeded the allowable

current.

Gr.1 No

A.300

Regeneration Error There is an error related to regeneration. Gr.1 Yes

A.320

Regenerative Overload A regenerative overload occurred. Gr.2 Yes

A.330 Main Circuit Power Supply

Wiring Error

• The AC power supply input setting or DC power

supply input setting is not correct.

• The power supply wiring is not correct.

Gr.1 Yes

A.400

Overvoltage The main circuit DC voltage is too high. Gr.1 Yes

A.410

Undervoltage The main circuit DC voltage is too low. Gr.2 Yes

A.50D

Position Deviation

between Axes Overflow

Alarm

The position deviation between axes A and B

during the servo ON state exceeded the setting

value of Pn66A (Position Deviation Between Axes

Overflow Alarm Level).

Gr.1 Yes

A.510 Overspeed The motor exceeded the maximum speed. Gr.1 Yes

A.51A Synchronized Stopping

Overspeed Alarm

The feedback speed of the axis undergoing syn-

chronized stopping has more than doubled from

the starting speed of synchronized stopping.

Gr.1 Yes

A.520 Vibration Alarm

Abnormal oscillation was detected in the motor

speed.

Gr.1 Yes

A.521 Autotuning Alarm

Vibration was detected during autotuning for the

tuning-less function.

Gr.1 Yes

A.550

Maximum Speed Setting

Error

The setting of Pn385 (Maximum Motor Speed) is

greater than the maximum motor speed.

Gr.1 Yes

A.710 Instantaneous Overload

The Servomotor was operating for several sec-

onds to several tens of seconds under a torque

that largely exceeded the rating.

Gr.2 Yes

A.720 Continuous Overload

The Servomotor was operating continuously

under a torque that exceeded the rating.

Gr.1 Yes

A.730

Dynamic Brake Overload

When the dynamic brake was applied, the rota-

tional or linear kinetic energy exceeded the

capacity of the dynamic brake resistor.

Gr.1 Yes

A.731

A.740 Inrush Current Limiting

Resistor Overload

The main circuit power supply was frequently

turned ON and OFF.

Gr.1 Yes

A.7A1

Internal Temperature Error

1 (Control Board Tempera-

ture Error)

The surrounding temperature of the control PCB

is abnormal.

Gr.2 Yes

Continued on next page.

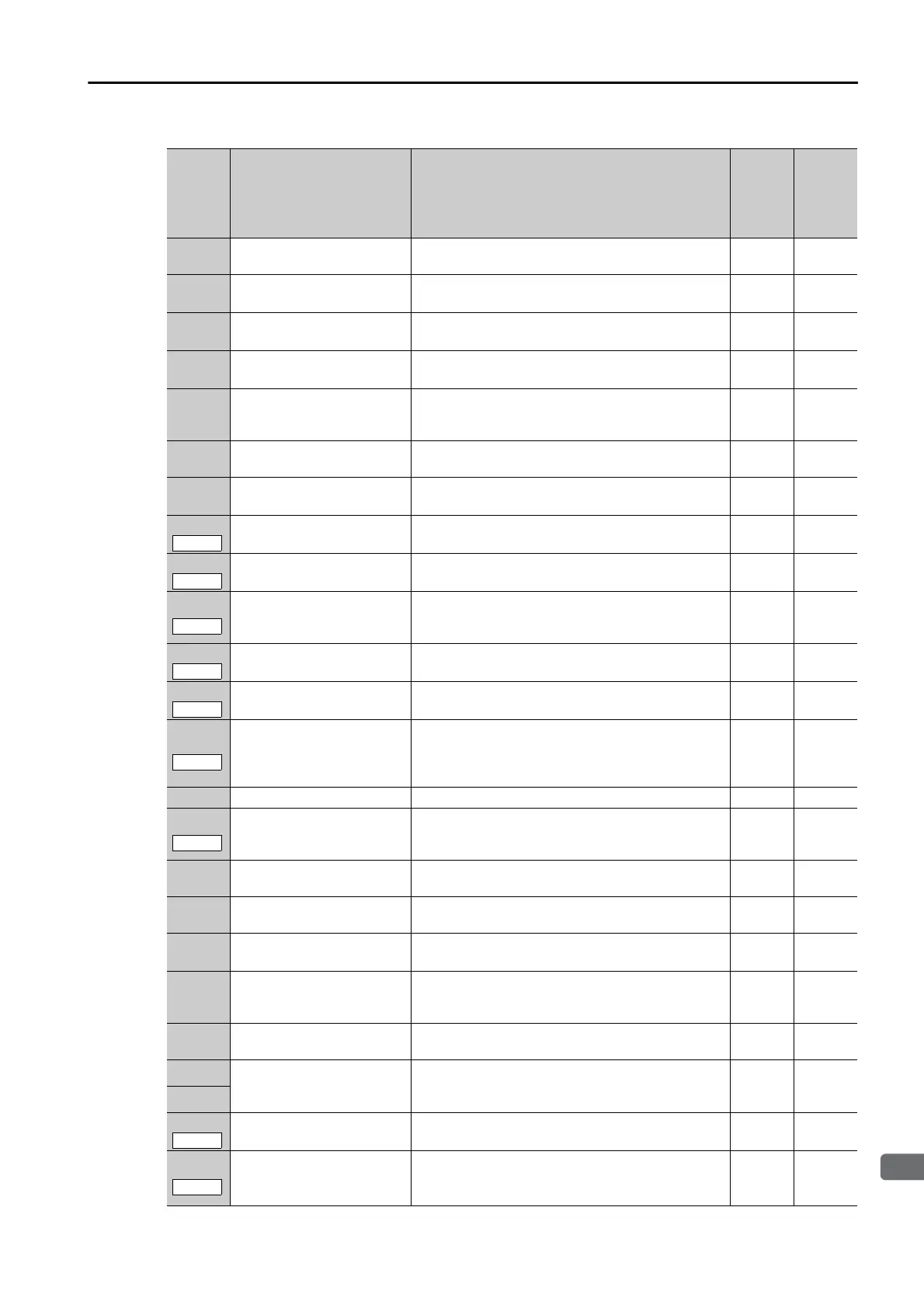

Continued from previous page.

Alarm

Number

Alarm Name Alarm Meaning

Servo-

motor

Stop-

ping

Method

Alarm

Reset

Possi-

ble?

Loading...

Loading...