Appendix I

ZCast Design Guide - 14

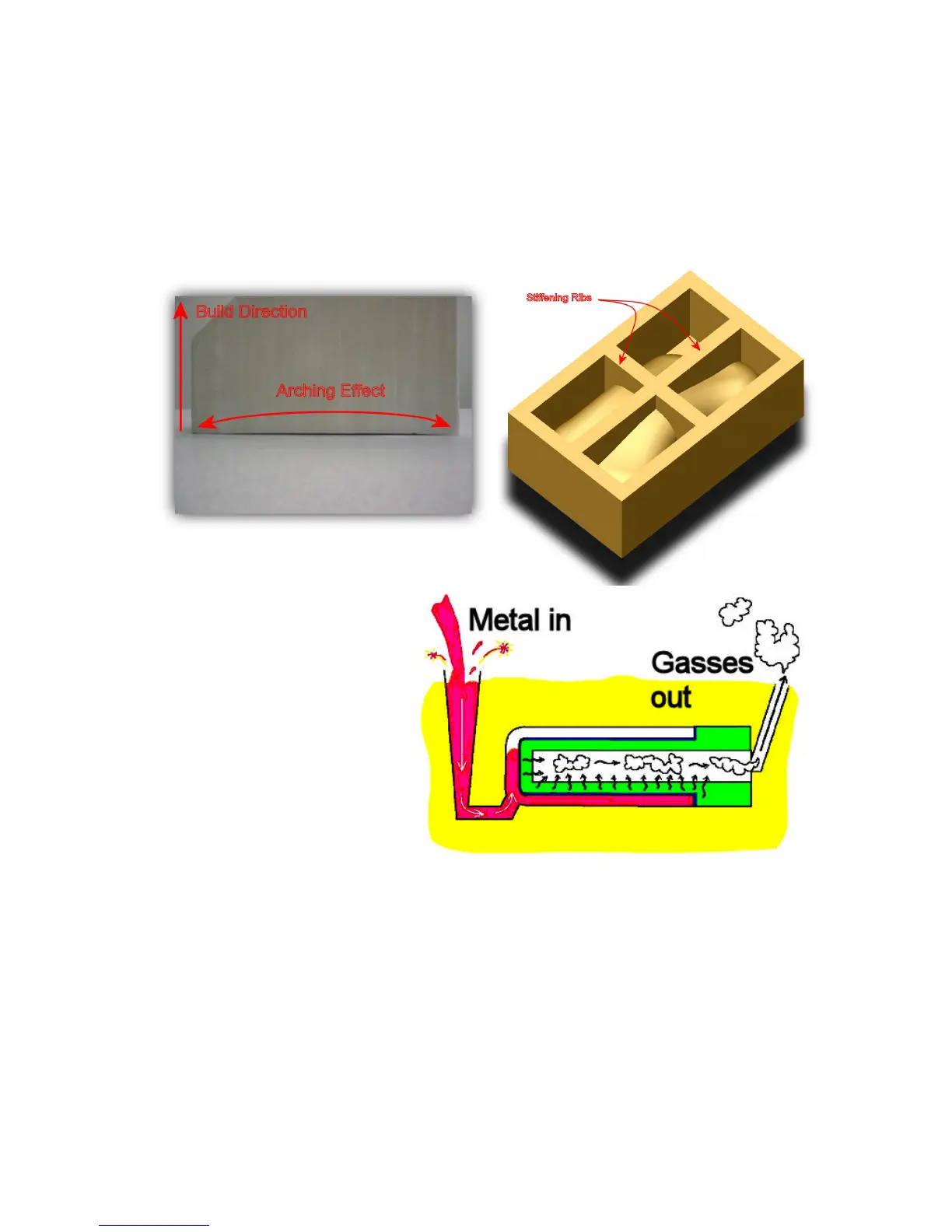

Arching is a phenomenon that occurs on the first few layers printed. It diminishes as the part

continues to build. To minimize arching, print the non-critical faces of your mold facing

downwards.

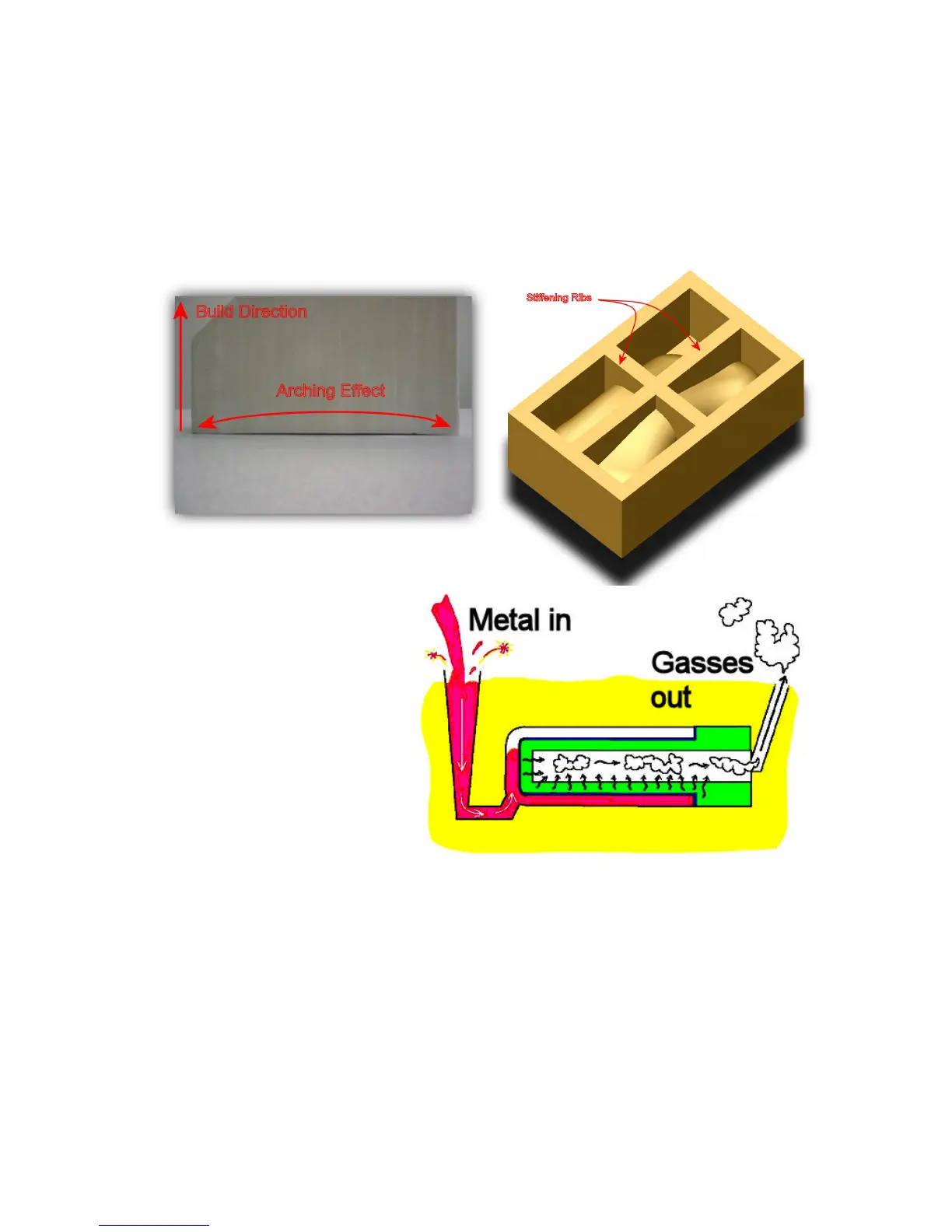

6.5 Venting

Perhaps the most important

concept in ZCast mold design is

venting. The mold must be

properly vented to avoid entrapping

gases in the cast part, and, more

importantly, to avoid violent release

of gases through the molten metal.

For those familiar with traditional

sand casting, it will be observed

that a ZCast mold (even when

properly vented) may smoke more

than conventional foundry sands.

Vents can be small holes (usually

at high points on the casting) extending through the cope to the atmosphere. These are often

small enough (.125” (3mm) is recommended) to freeze off before the metal reaches the exterior

of the mold.

Vents also must be used in cores (figure 9). When molten metal comes in contact with ZCast

compounds, out-gassing occurs. If the cores were solid, the gas would have nowhere to go but

into the metal. When gas passes through the metal as it cools, it can be trapped, forming pockets

called porosity. To avoid this, the cores can be hollowed with the hollow sections vented through

the core print to the outside of the mold. It is important to keep the venting path away from the

metal path. The core vents should be

Figure 8: Arching

Figure 7: Addition of

stiffening ribs printed in the

shelled mold

Loading...

Loading...