54 service@zcorp.com

INFILTRATING THE PART WITH Z-KOTE RESINS

All parts can be infiltrated with a variety of resins to produce a range of material properties. As an early stage

design tool, it may not be necessary to infiltrate the parts at all. However, the true versatility of the Z Corp. System

is derived from the spectrum of material properties that can be achieved by applying one of our infiltration materials

to parts. For additional information on how Z Corp. customers are utilizing our line of infiltration products, call us

at Z Corporation, or visit our user group website at www.zcorp-users.com. Here you will find a variety of application

stories and technical tips that describe the many ways that our system can benefit your operation.

USING Z-MAX

TM

EPOXY

Z-Max epoxy is a high strength epoxy infiltration system specifically formulated for Z Corporation. Z-Max epoxy

is a low viscosity, high strength, infiltration system designed to fortify both starch and plaster-based parts built on

all of Z Corporation’s three-dimensional printers. Z Corp. parts infiltrated with Z-Max epoxy are easily sanded

and are surface machinable.

SAFETY PRECAUTIONS

• Wear lab coat, gloves (we recommend PVC Examination Gloves), face shield or goggles. Face shield

is required if spraying. Apply in ventilated hood.

• Specialized containers recommended for dispensing and application. System for avoiding spills: Catch

pan, waxed paper, or plastic drop cloth.

• Label disposal materials.

• Wear dust mask when sanding finished parts.

• Please read the Material Safety Data Sheet for Z-Max epoxy prior to the use of this material.

MIXING INSTRUCTIONS

• Mix 100 parts Z-Max Resin to 37 parts Z-Max Hardener by weight or 100 parts Z-Max Resin to 41

parts Z-Max Hardener by volume. Mix the two parts thoroughly for two minutes before application.

The material has a working time of 35 minutes in a 425 gram mass. Please be aware of the gel time

while preparing quantities of material as the gel time decreases as the quantity of material increases.

It is recommended not to mix quantities over 425 grams.

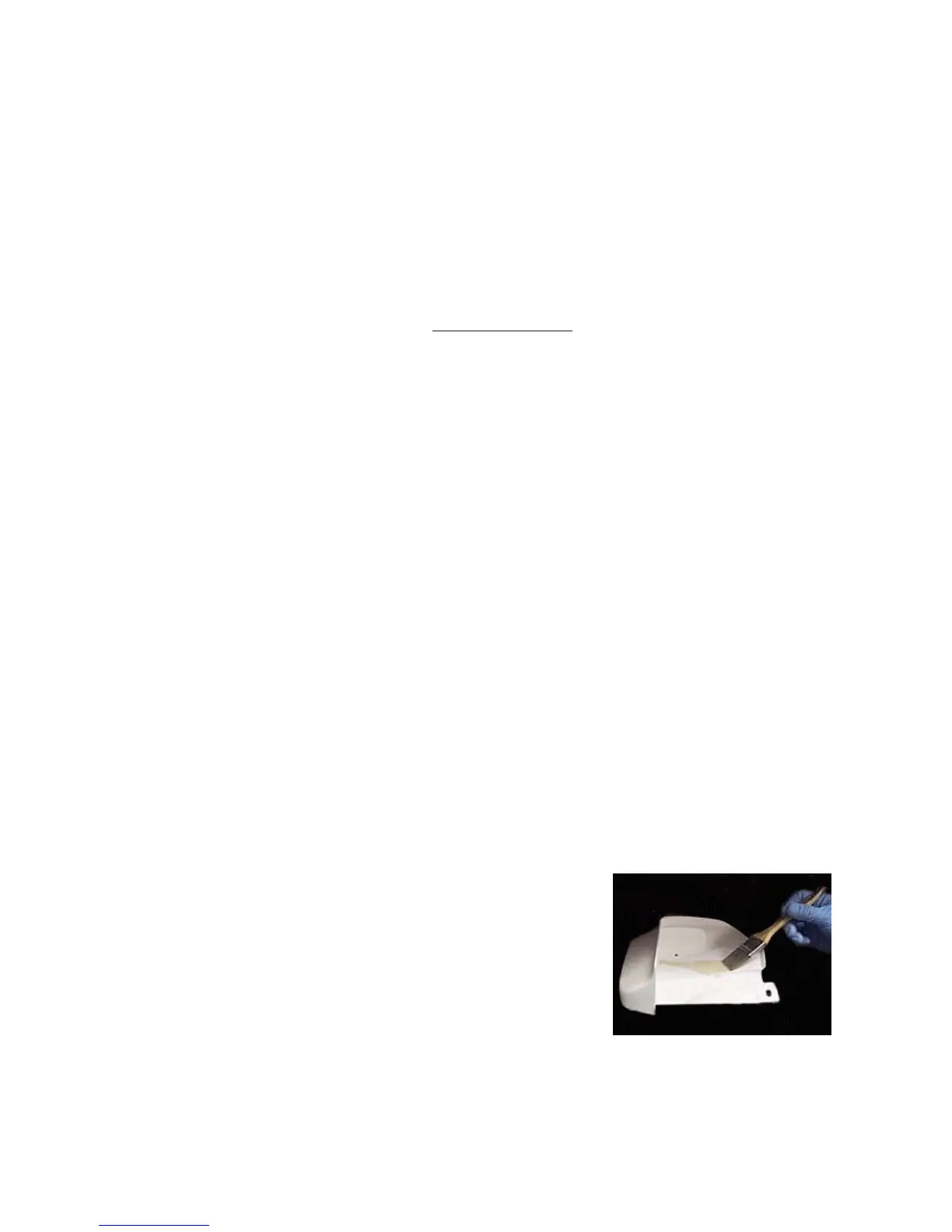

GENERAL APPLICATION

• Material can be brushed or sprayed.

• Material will penetrate between 0.079- 0.28 (2 – 7 mm).

• Do not over apply the material, as it will pool off the part during

curing.

• Better penetration depth is achieved by applying several light coats

of material.

• Allow all mixed materials to cure prior to disposal.

Loading...

Loading...