Appendix I

ZCast Design Guide - 23

8 Pouring Metal

8.1 Metal Types

The current product offering is ZCast 500 powder and is designed for low temperature, non-

ferrous metals (MAX TEMP 1100°C (2000°F)). The higher the temperature of the metal, the

more gassing on contact there will be. It becomes a serious risk that the mold will gas violently,

potentially exploding, as these temperatures are exceeded. Therefore, do not attempt to pour

non-ferrous metal into ZCast 500 molds.

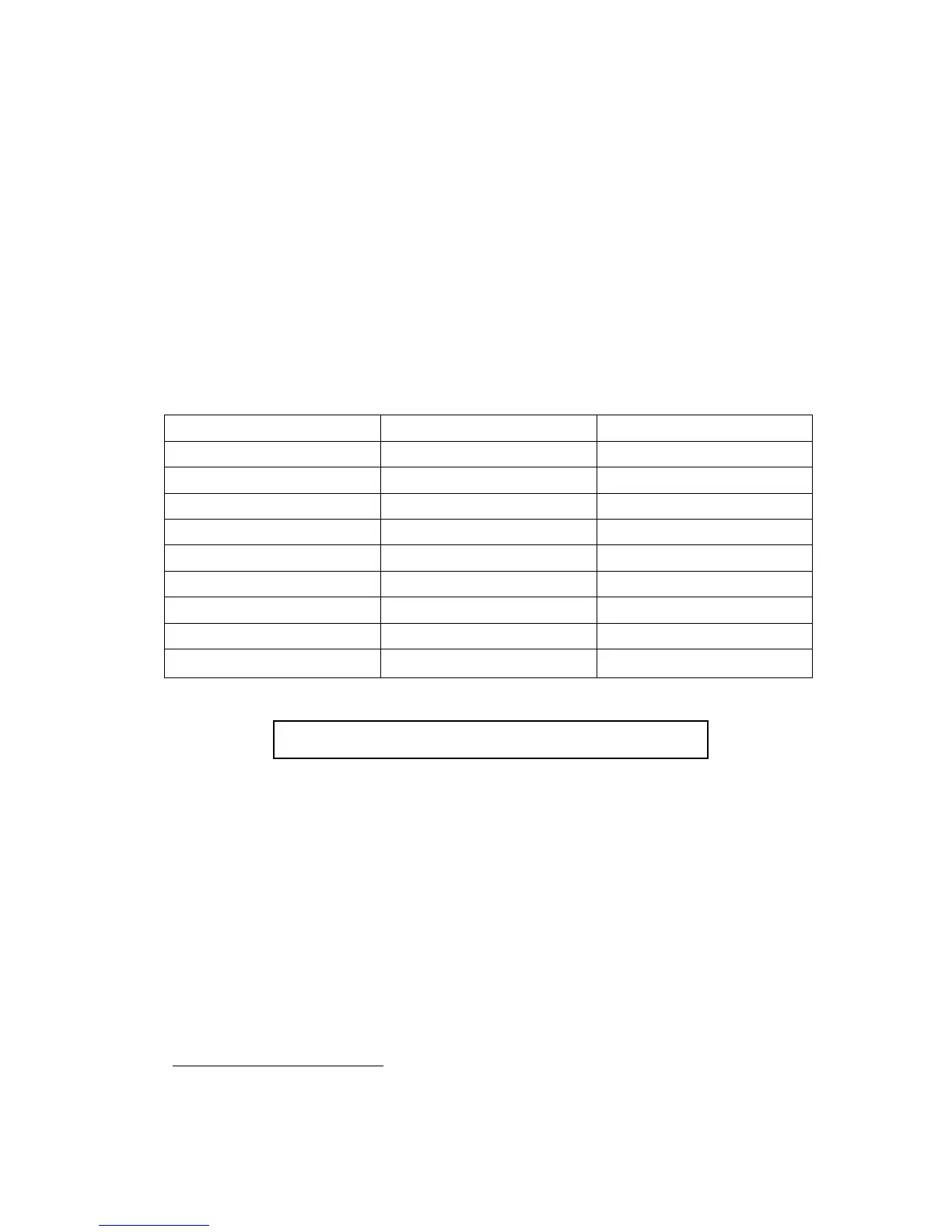

Z Corp. tested and approved materials:

Alloy Pouring Tempratures Melting Temperature(s)

Aluminum 319 1250°F – 1450°F

5

1120°F

Aluminum 356 1250°F – 1450°F

5

1135°F

Aluminum 390 1250°F – 1450°F

5

1156°F

Bronze Silicon 1900°F – 2150°F

6

1880°F – 1940°F

Bronze Phosphor 1900°F – 2150°F

6

1830°F – 1970°F

Bronze Aluminum 1900°F – 2250°F

6

1915°F – 1930°F

Brass

5

1900°F

6

1850°F

Zinc 750°F – 800°F

7

1090°F

Magnesium

8

1400°F – 1500°F

7

Flammable

WARNING: NO ATTEMPT SHOULD BE MADE TO POUR

FERROUS METALS IN ZCAST 500 MOLDS

9 Material Handling

9.1 Storage

Though ZCast powder

has no special storage requirements; it should be stored in a cool, dry

environment. See container labels for additional information.

9.2 Disposal

ZCast powder is a non-toxic substance. Please consult the Material Data Safety Sheet for

product details. Dispose of ZCast powder according to local and state regulations.

5

ASM metals handbook, 4

rth

edition

6

Heine & Rosenthal

7

Foseco foundryman’s handbook

8

Consult Z Corporation prior to pouring

Loading...

Loading...