64 service@zcorp.com

ELECTROPLATING

Parts printed on the ZPrinter 310 can be easily prepared and electroplated for the look and feel of a metal part.

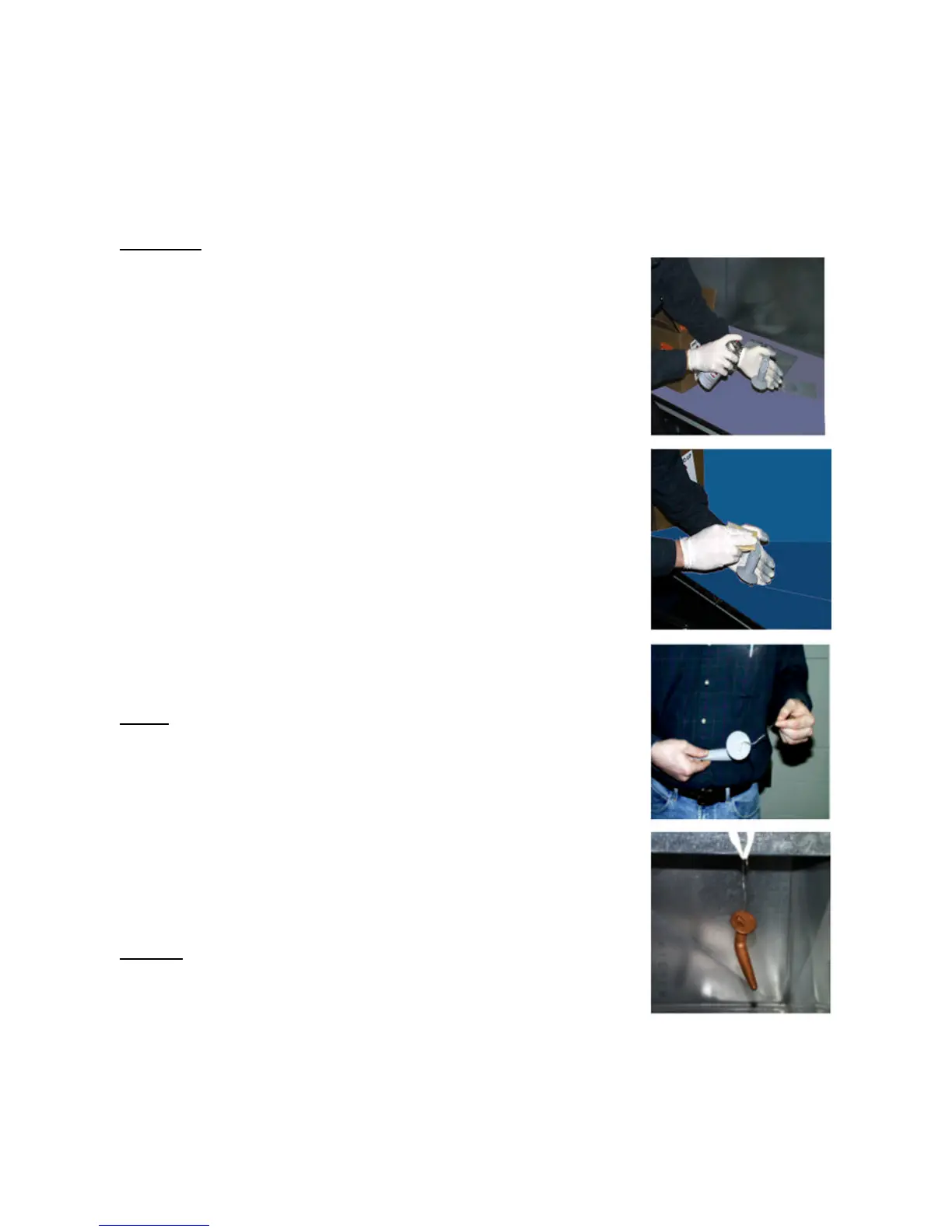

Preparation

Preparation is the most important step in producing a good electroplated surface.

1. Both starch and plaster-based powder parts can be used as the base parts for

electroplating. Parts should be well infiltrated with cyanoacrylate resin or epoxy

and sanded with 220-grit sandpaper. Do not wax the parts.

2. Spray parts with a sandable primer (such as Rust-Oleum Auto Primer), let dry,

and sand again. In order to create a smooth metal finish, the part must be sanded

as smooth as possible.

3. Once sanded to satisfaction, clean the part with a damp paper towel.

4. To aid in the spraying process, and make it easier to get a good contact when

plating, it is a good idea to attach wire before painting the parts. Wire can be

attached to any non-visible surface with cyanoacrylate resin.

5. After the wire is securely attached, spray the entire part, including the wire,

with a conductive paint. There are a variety of conductive paints on the market

(such as Agri Systems Non-Stick Graphite Paint, as well as Dalmar Easyplate

Copper Conductive Paint).

6. The conductive coating is critical to good plating. Spray all parts well and

evenly. Do not leave any surface uncoated. Be especially careful of where the

part is held while you spray it. Do a second coating to cover these spots.

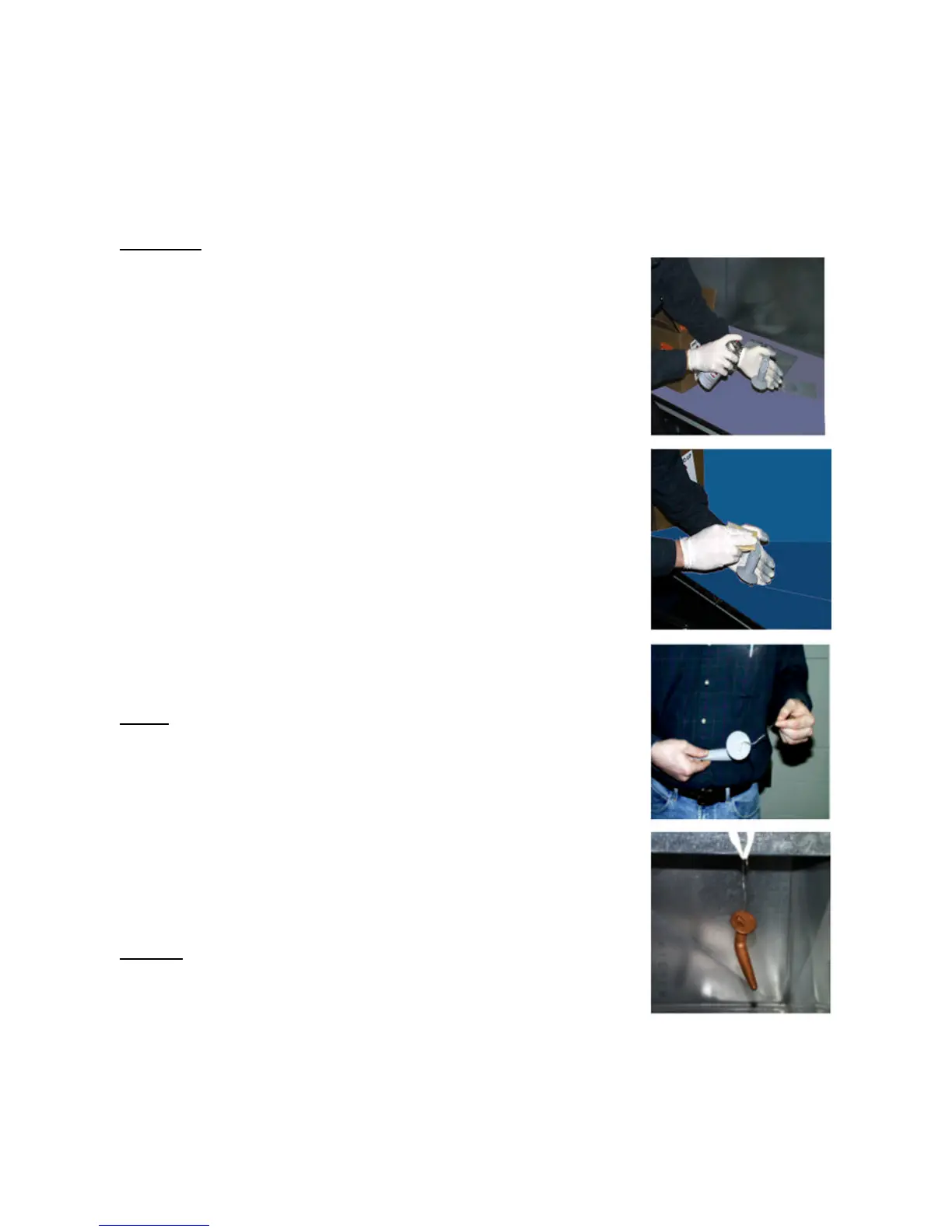

Plating

While any electroplating shop should be able to plate the parts at this point, it is a

good idea to find a shop that has experience with plating nonconductors, when

possible.

During the plating process, the first bath will be a copper strike. This bath will use

a relatively low current. The paint you use may come with directions for the

current and voltage that should be used for this coating. If not, a good guideline

is to start at 1 to 2 amps/square foot and increase that amount as the part starts

to plate. Once this first layer has been plated, the following coats can be plated

as normal. If the surface is not leveling, it can be sanded in between baths to

help get a shiny finish.

Contacts

If you would like to have a part plated, we recommend contacting Jason Channell

at Associated Electroplaters, Inc. Phone Number (248) 547-5520.

Loading...

Loading...