Appendix I

ZCast Design Guide - 17

6.8 Mating Surfaces

The mating surfaces of the mold should be offset to accommodate for surface imperfections. A

total gap of 0.020” (0.5mm) should be created, in the model, at all mating surfaces. The offset

can be created on either side of the parting surface or split between them.

Even with an intentional gap, there will likely be

some portion of the mold or core that rubs against

another part when the mold is assembled. When

one ZCast object rubs against another ZCast object,

they essentially sand each other down, leaving a

little bit of loose sand. Since this is bound to

happen, you should prepare for this by leaving room

between cores and core prints, and, where possible,

at junctions on the parting line, taking care not to

extend this gap into the path of metal. Add a small

radius the bottom edges of core prints where they sit

in the cope or drag; this provides space for loose

powder to collect safely away from metal flow.

A foundry will typically seal parting surfaces with

core paste. A bead of this material is placed around the outer edges of the mating surfaces of the

mold and across the core prints to prevent leakage.

6.9 Geometry Guidelines

For the majority of metals that can be poured in ZCast 500 molds, the following are the geometric

limitations:

• Minimum core size – 3.5 to 4.0mm. some distortion will occur of small cores project

across large distances.

• Minimum cast feature size (positive feature) – 3.0mm (thinner ribs have been cast, but

there are limits on how far the feature can extend)

• Volume – no tested limit. Size limitations are related to build size, however molds can

also be built in sections and assembled to make much larger molds.

• Closed/nearly closed volumes – if the core does not have enough body at the core print

to support itself (for example the core of a two liter soda bottle – very narrow neck with

respect to the size of the core), then the core may break in the mold. If the core narrows

down at the core print so that the bulk of the core cannot be vented, then there is risk of

high porosity in the casting.

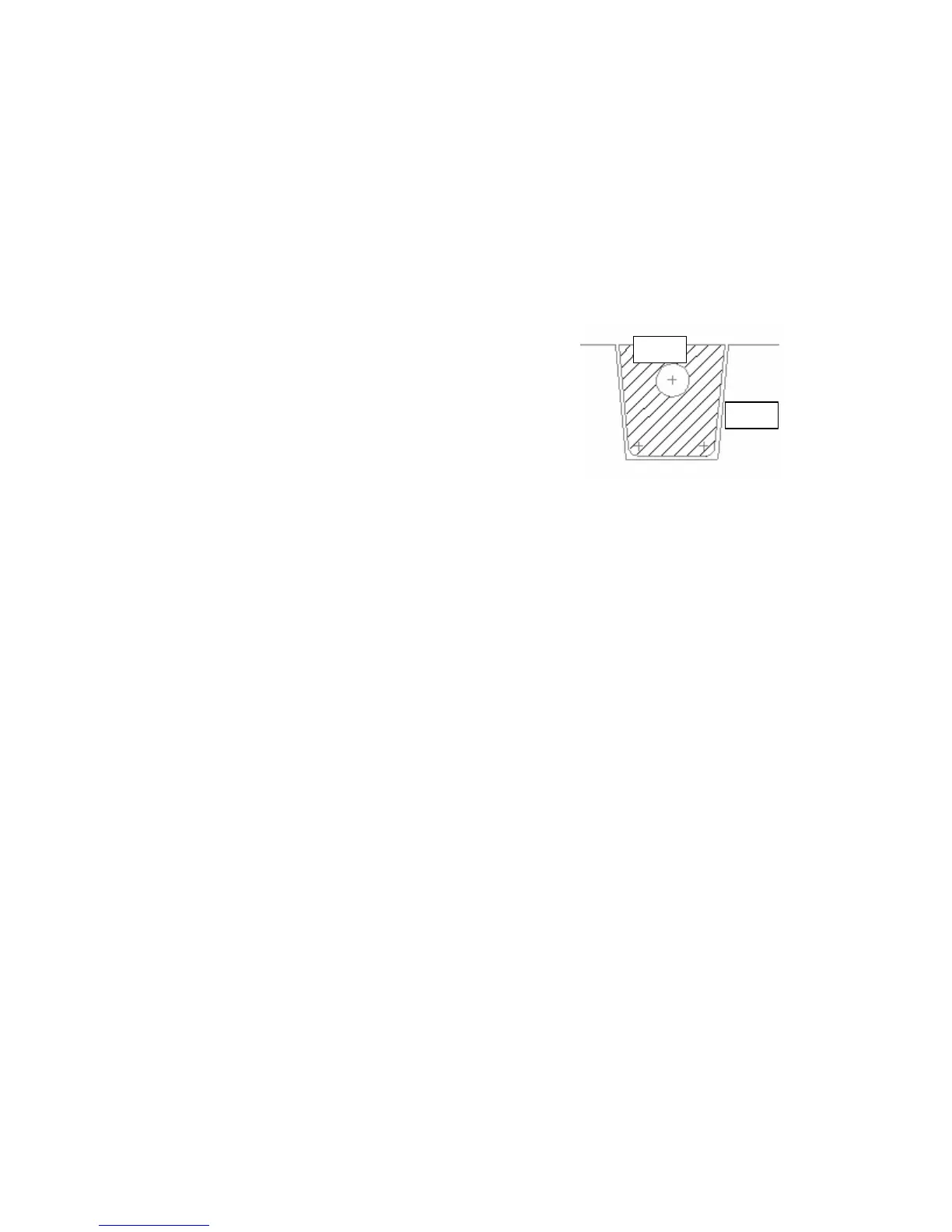

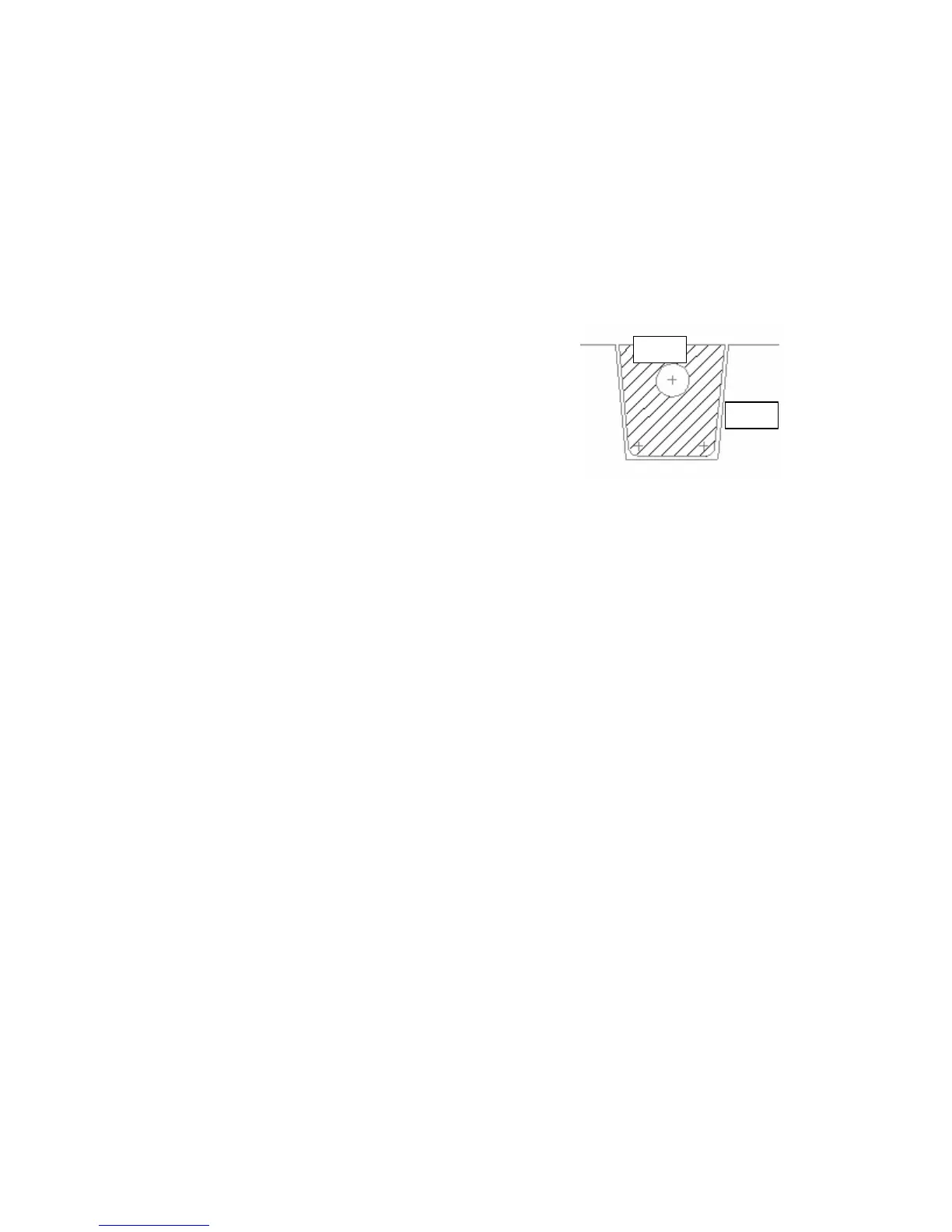

Figure 11: Tapered core and core print.

Core has radiused bottom edge. Add

offset between mating surfaces.

Core

Loading...

Loading...