49www.zcorp-users.com

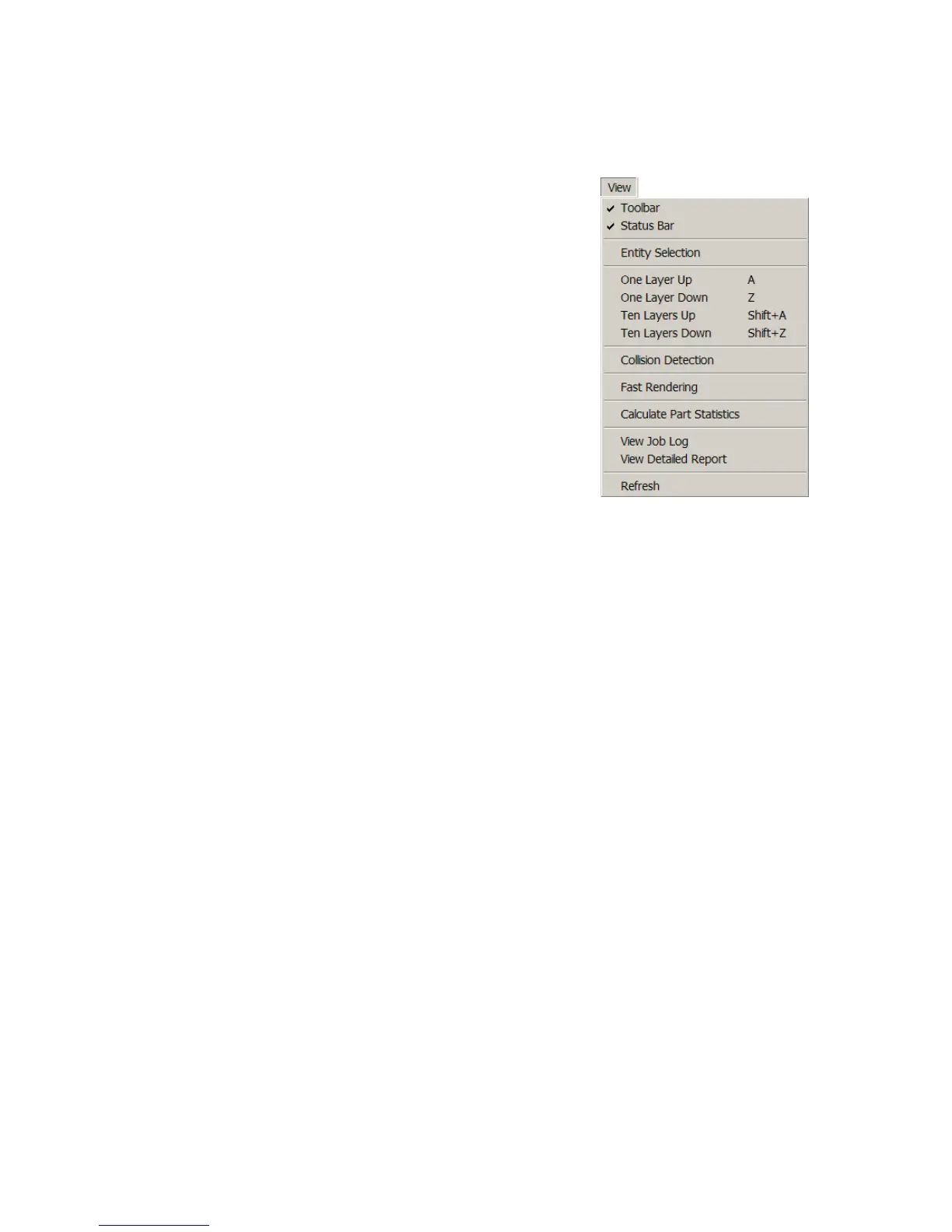

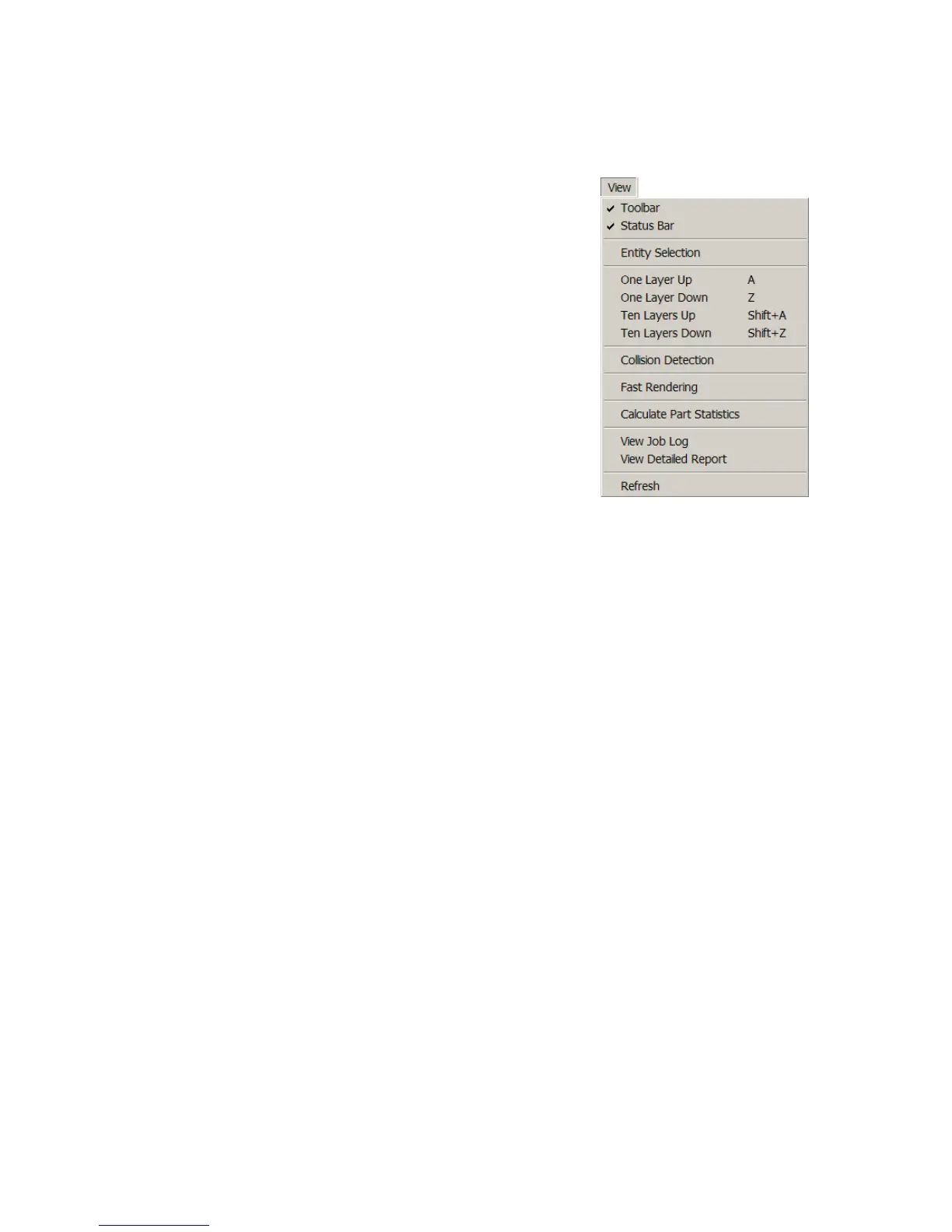

• It is also strongly recommended that slice viewing and collision

detection (if more than one part is being printed) be used before

start the build. These features are found under the View menu.

• Slice viewing allows you to view the cross sections of the part

to identify any slice errors.

• Collision detection will scan through the slices and report the

layer in which part overlapping is found.

SETTING POWDER PARAMETERS

ANISOTROPIC SCALING VALUES

Anisotropic scaling values scale the model to accommodate any shrinkage or expansion of the part either due to

characteristics of the material system or infiltrant system being utilized. A scaling value of one (1) is equal to

100% of the part in a specific axis. If the part shrinks 1% in a certain axis, the correct anisotropic scaling value

would be 1.01 in that axis. The ZPrint Software will display the recommended values for each powder type. The

scaling factors may differ according to wall thickness and geometry of the part. A higher accuracy level may be

obtained by measuring the part and adjusting anisotropic scaling values as needed. To obtain new anisotropic

scaling factors that are part specific, print the part with scaling factors of one (1) in all axes. Once the part is

completed, post-process the part. Measure the x-, y-, and z-axes. Divide the nominal value by the measured

value. For example, if the printed part had a nominal value of 1 and had a measured value of 0.98, the scaling

value would be 1.02. After calculating the anisotropic scaling values, input them into the software and reprint the

part and follow the post-processing procedure.

1. Plaster Material System

The plaster material system has been found to remain dimensionally accurate during printing and thus, the

recommended anisotropic scaling values are one (1) in all axes. If the infiltrant system being used changes the

accuracy of the part, please alter the values as needed.

2. Starch Material System

The shrinkage found in the starch material system is proportional to the part geometry and the drying time of the

part. The longer the part is left to dry, the larger the shrinkage value. The part is most stable in the x and y-axis and

shrinks more in the z-axis. Thus, the anisotropic scaling factor of the z-axis will always be greater than the values

for both the x- and y-axes.

3. ZCast Material System

The ZCast material system has been found to remain dimensionally accurate during printing and thus, the

recommended anisotropic scaling values are one (1) in all axes.

Loading...

Loading...