71www.zcorp-users.com

THERMOFORMING

This process consists of heating a thermoplastic sheet to a formable plastic state and then applying air pressure

and/or mechanical assists to shape it to the contours of a mold. In this process, the air pressure may range from

almost zero to several hundred psi. ‘Vacuum forming’ is the term given when a pressure differential of up to

approximately 14 psi (atmospheric pressure) is used. The pressure is obtained by evacuating the space between

the sheet and the mold in order to utilize this atmospheric pressure. Vacuum forming will give satisfactory

reproduction of the mold configuration in the majority of forming applications. Manufacturers can use all types of

thermoplastic materials – PVC, polystyrenes, polyesters, acrylics etc. in this process.

Making light gauge (plastic less than 0.060" or 0.15 mm) thermoforming molds for prototype parts is an ideal use

for Z Corporation 3D Printers and plaster powder.

For more information regarding the process and the industry, check out SPI’s website: www.plasticsindustry.org/

index.htm where you can search SPI’s Membership Directory & Buyer’s Guide for thermoformers.

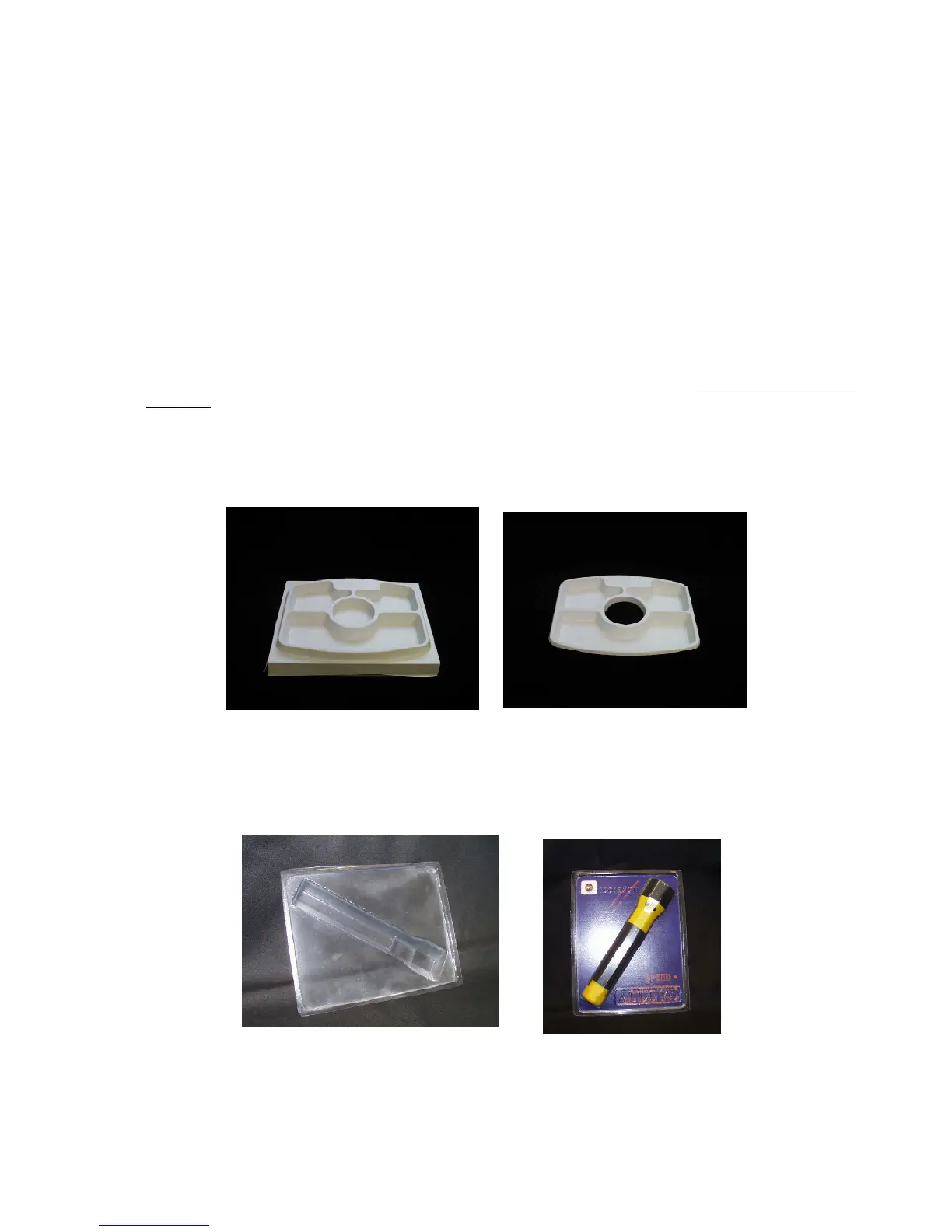

In the example below, the industrial designer wanted to get a feel of his design in the actual material. He was able

to generate a mold and produce a sample in a period of days.

The packaging company that produced the prototypes below uses the parts to generate samples for their sales

department, who then use them to collect customer feedback.

Mold Prototype

Loading...

Loading...