63www.zcorp-users.com

POLYESTER RESIN

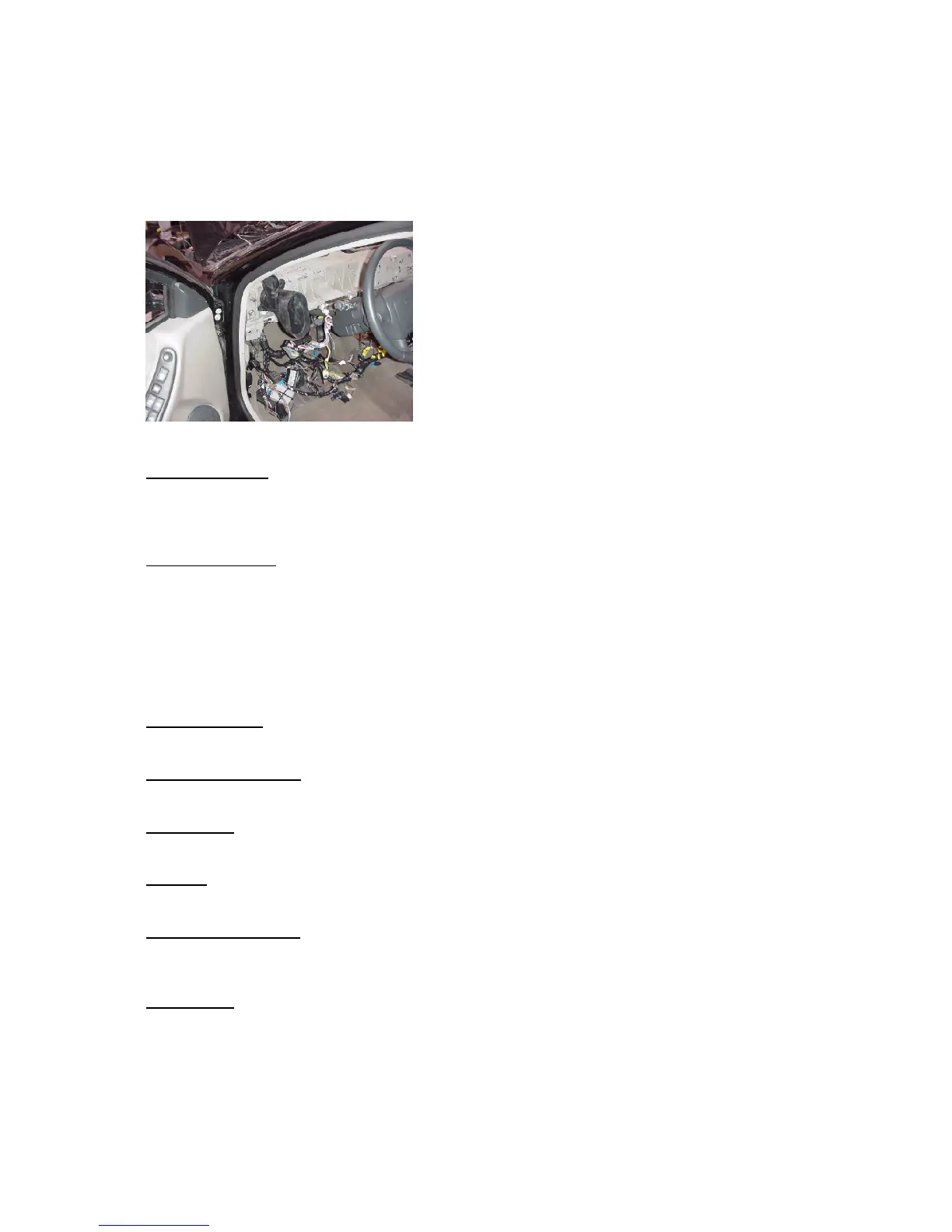

Many types of transportation equipment require the use of geometri-

cally complex ducting for heating, ventilation and air conditioning

(HVAC) of the interior space. Prototype ducting produced on the Z

Corporation 3D Printer can be used for form and fit testing, as well

as air-flow testing across a range of temperatures and humidity. The

parts can be prepared to have sufficient toughness and resiliency to

survive bench testing and functional testing in an automobile.

The basic parts are produced in zp15e starch powder. It is recom-

mended to print a sample part first to practice all the process steps

if you are a new user. This step is worthwhile, especially when deal-

ing with large parts because it will help to minimize waste and to

increase efficiency.

Infiltration Details

This application requires use of a marine-grade, thixotropic, low viscosity polyester resin. This resin is widely

available at hardware stores and industrial supply centers. Some common manufacturers are Evercoat, Fibre

Glast, and/or FiberLay.

Materials Required

• Polyester resin and catalyst

• Plastic container for resin

• Disposable brushes

• Fiberglass mat (optional) Kevlar, E-, S-glass mat

• CA or equivalent glue for joining assemblies

• Personal Protective Equipment (Gloves, Eye protection, Apron)

Application Time

Highly dependent on part 5-30 minutes

Application Technique

Applied by brush

Working Life

15 Minutes

Set Time

4 hours (minimum)

Environmental Setting

Please read the Material Safety Data sheets for these products carefully. This operation should be conducted in

a well ventilated area with protective eyewear.

Instructions:

1. Depowder and air dry parts for a minimum of four hours.

2. Apply the resin by brush to individual parts per the material’s directions and allow them to cure.

3. Sand as needed and check any critical dimensions. Finally, use cyanoacylate (resin) to construct any multi-

part assemblies as required.

4. Apply polyurethane resin.

Loading...

Loading...