73www.zcorp-users.com

RTV MOLDING

Room Temperature Vulcanization (RTV) molding, also known as Silicone Rubber Molding

(SRM), is an inexpensive soft molding solution for creating dozens of prototypes

accurately. The benefit of RTV molding is that anyone can do it because of its simplicity.

Factors such as draft

1

, complex parting lines

2

and undercuts

3

are not factors in building

effective molds as they are when using hard tooling. Additionally, hard tooling may not

be practical during the design process due to cost, production time, and likelihood of

design changes. RTV molding effectively bridges the gap between one off prototypes

and hard tooling in a fraction of the time.

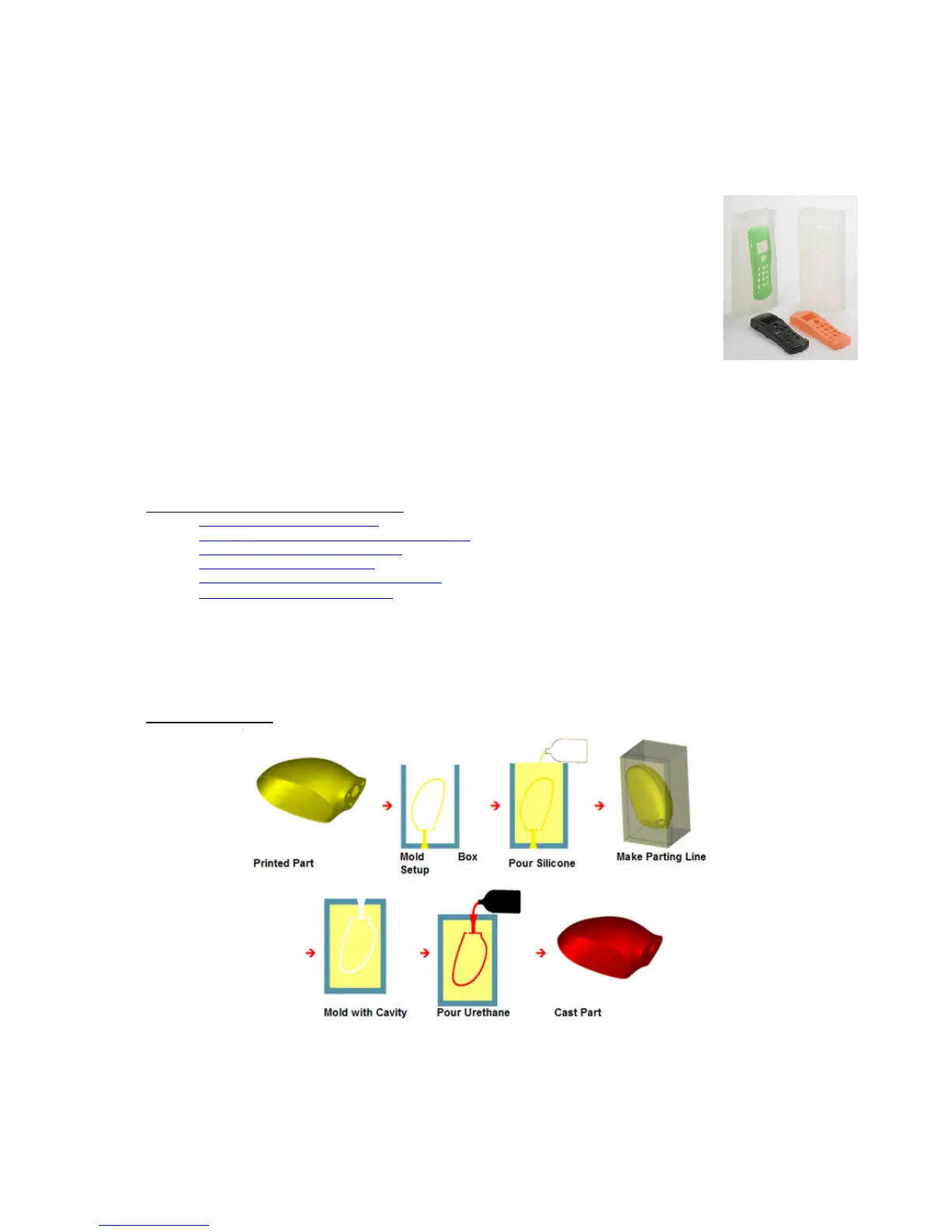

RTV molding requires the production of a single master pattern, which is encased in low

durometer

4

silicone rubber. Using a part printed on a Z Corporation 3D Printer is the fastest and least expensive

method for creating a pattern for RTV molding. Once the silicone rubber, encasing the pattern, cures (2 – 48

hours depending on chosen material) the master is cut out, leaving a cavity. The cavity is used as a soft rubber

tool for molding investment casting wax, epoxy, foam, or in most cases polyurethane or a similar thermoset

material that has physical properties similar to injection-molded themoplastics. Cast prototypes will have the

look and feel of a production piece.

Additional Resources for the Novice Mold Maker

www.build-stuff.com/002book.htm

www.bare-metal.com/articles/gremlins_how_to.htm

www.smooth-on.com/moldmaking.htm

www.eagerplastics.com/intro.htm

www.theminiaturespage.com/ref/fgmolds.html

www.micromark.com/part_mold.html

The quality of the pattern directly affects the quality of the part from the RTV mold because RTV rubber molds

will pick up details as fine as a fingerprint from the master pattern. Master patterns are classically sanded and

polished regardless of the method of their production. This makes parts printed using Z Corporation technology

a perfect fit due to the ease in which their surface finish can be enhanced.

Process Overview

1

Draft Angle – A slight taper to the shape of a cast part to allow it to be easily removed from its mold. Draft angles should be used on interior or exterior part walls in the

direction of draw. A minimum 1° draft angle per side is recommended for parts having no textured surfaces. Textured surfaces need additional draft to easily release the part,

and eliminate drag marks or scuffing of the part surface.

2

Parting Line – Line in which two halves of a mold will separate. Parting lines should be located to provide good part appearance and function.

3

Undercut – A protuberance or indentation that impedes withdrawal from a two-piece rigid mold.

4

Durometer – The hardness of a material. RTV molds typically use a material with a Shore A hardness <50.

Loading...

Loading...