76 service@zcorp.com

Once the de-gassing is complete; pour the silicone mixture slowly

into the mold box, letting it run smoothly around the pattern. Take

your time to decrease the chance of air being trapped anywhere.

Best practice is to de-gas the mold after the silicone has been

poured to remove any air that was introduced.

Manufacturers of Vacuum Chambers and Casting Systems

BJB Enterprises (www.bjbenterprises.com/equipment)

Innovative Polymers (http://www.innovative-polymers.com/)

MCP Equipment (www.mcp-group.com)

Removing the Master Pattern and Creating the Parting Line

Remove the mold box from around the mold. Using a razor blade or

scalpel, begin to cut the mold open at the gate and vent. This will begin

to create the parting line for the mold. Cutting in a smooth zigzag

motion will make the mold halves easier to re-assemble in preparation

for urethane casting. Slowly cut deeper to the edge of the pattern.

Keep in mind where the mold parting line will be on the pattern. The

parting line should be placed on an edge of the part to avoid witness

lines (flash

1

from the cast urethane).

When the cut is finished, the mold halves should easily separate and

the master pattern can be removed.

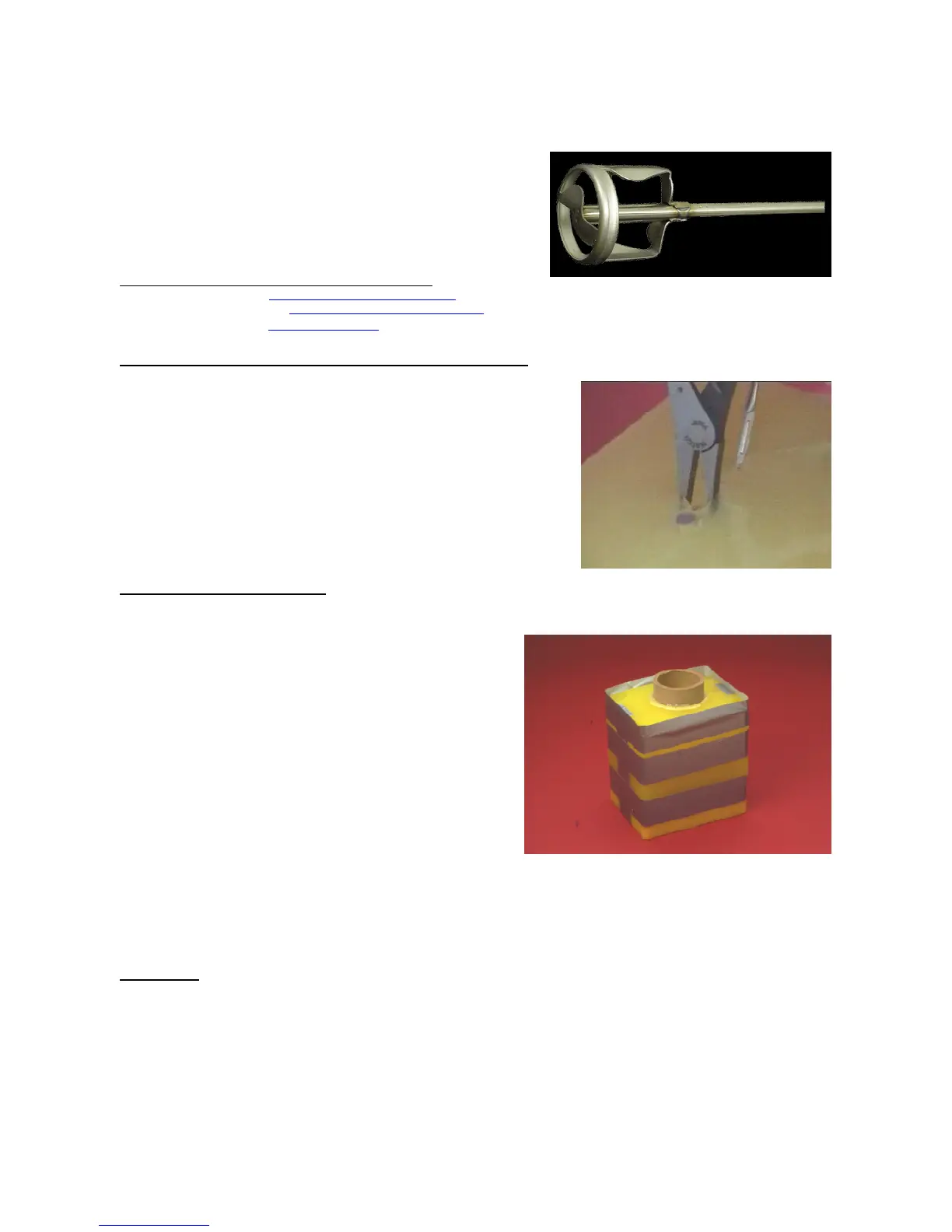

Mold Preparation and Casting

Spray mold release onto all areas that will be exposed to the casting material and place the mold halves together.

Use tape, rubber bands, or clamped boards to hold the mold

together, preventing the cast urethane from leaking through

the parting line. Do not squeeze a soft mold too tightly as the

mold cavity may flex or distort. A cup or sprue is usually placed

at the gate of the mold as a receptacle for pouring or injecting

the casting material.

Preparation and dispensing of the casting materials varies.

Two-part urethanes are typically packaged in cartridges and

dispensed through a handheld pneumatic static mixer for

smaller scale applications. Automated meter mix dispense

equipment is usually used by small production facilities. The

use of hand pumping static mix dispensers is not recom-

mended, as they tend to produce off ratio mixtures.

Placing the mold in pressure pot after material has been cast

into it to minimize any bubbles present is a common practice. This will reduce the effects trapped air will have on

the final part.

Follow the cure cycle of the cast material before attempting to de-mold the cast part.

Conclusion

RTV molding is an extremely efficient method of generating multiple parts with thermoplastic properties. There is

no faster method of generating the master pattern than with a Z Corp. 3D Printer, which will reduce the overall

time it takes to get your final cast part. Whether a Z Corp. 3D Printer is your complete prototyping solution or just

a piece of it, there is no tool more valuable at saving the things most valuable, your time and money.

1

Flash – Cast material that has squeezed into the space between mold halves, typically at the parting line.

Loading...

Loading...