VOLTAGE DROP TEST

The Voltage Drop Test is used to test for bad connections.

When performing the test, you are testing the amount of

voltage drop through the connection. A poor or corroded

connection will appear as a high voltage reading. Voltage

drop shown on the meter when testing connections should not

exceed 0.1 VDC per connection or component.

To perform the test, place the meter on DC volts and place the

meter leads across the connection to be tested. Refer to the

chart on next page to perform voltage drop tests on the starter

system.

Voltage Drop should not exceed: 0.1 DC volts per

connection

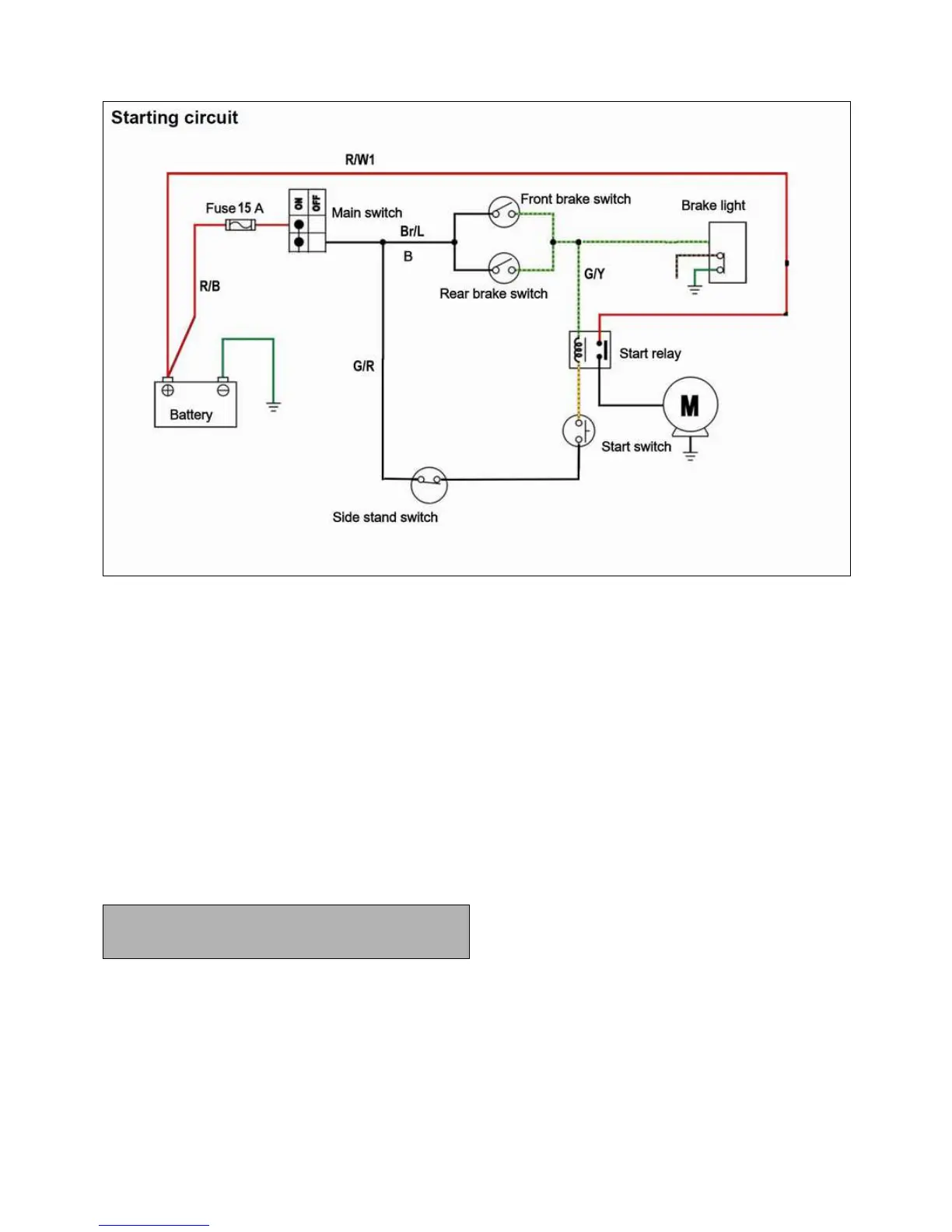

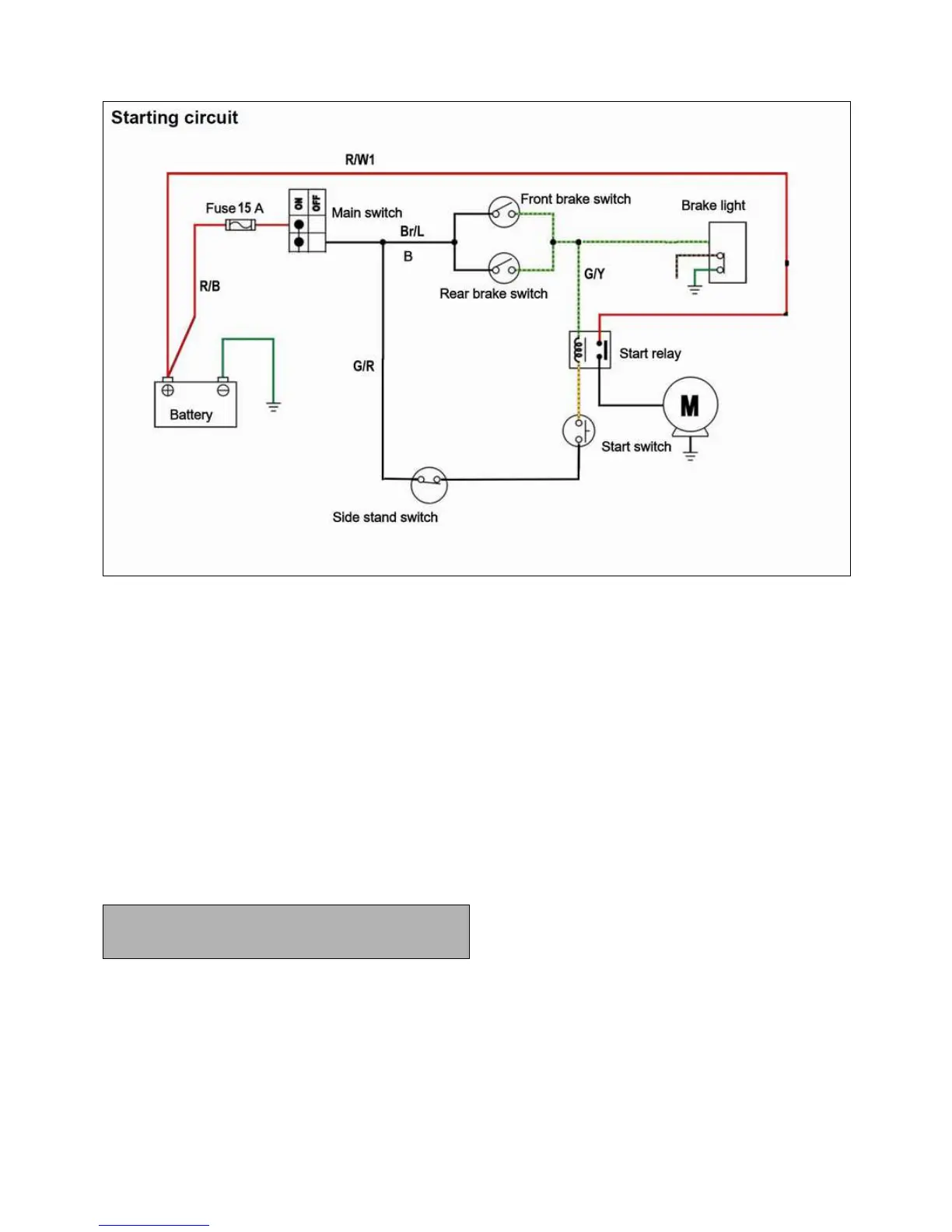

Use the illustration above and procedure below when

troubleshooting a “No Start” condition.

STARTING CIRCUIT OPERATION

The starting circuit on this model consists of the starter motor,

starter relay, brake light switch, and ECU and kick stand switch

If the main switch is “START” position, the starter motor can

be operated only if:

1. The kickstand on ground (kickstand tough ground). Or

2. The brake lever is not pressed (the brake light switch is

closed).

IF THE STARTING MOTOR FAILS TO OPERATE

FOLLOWING PROCEDURE TO CHECKING.

◎

◎◎

◎ FUSE

Ensure fuse (main, ignition, signaling system) continuity. If

broken, replace the fuse.

◎

◎◎

◎ BATTERY

Check the battery condition. The open-circuit voltage should be

12.8 V or more at 20 °C (68 °F).

If battery less than 11.8V inspect regulator and stator, recharge

or replace the battery.

Loading...

Loading...