ENGINE

4-91

STATOR HOUSING INSTALLATION

NOTE: The stator, flywheel, starter drive, and stator

can be serviced with the engine in the frame.

1. Apply a light amount of Crankcase Sealant to the mounting

surface and install a new gasket. Install the dowel pins.

SPARK PLUG FOULING

TROUBLESHOOTING

◎ Spark plug cap loose or faulty

◎ Choke cable adjustment or plunger/cable sticking

◎ Foreign material on choke plunger seat or plunger

◎ Incorrect spark plug heat range or gap

◎ Carburetor inlet needle and seat worn

◎ Jet needle and/or needle jet worn or improperly adjusted

◎ Excessive carburetor vibration (loose or missing needle jet

locating pins)

◎ Loose jets in carburetor or calibration incorrect for

altitude/temperature

◎ Incorrect float level setting

◎ CVT system calibrated incorrectly or components worn or

miss-adjusted

◎ Fuel quality poor (old) or octane too high

◎ Low compression

◎ Restricted exhaust

◎ Weak ignition (loose coil ground, faulty coil, or stator,)

◎ Restricted air filter (main or pre-cleaner) or breather

system

◎ Improperly assembled air intake system

◎ Restricted engine breather system

◎ Oil contaminated with fuel

◎ Restricted crankcase vent

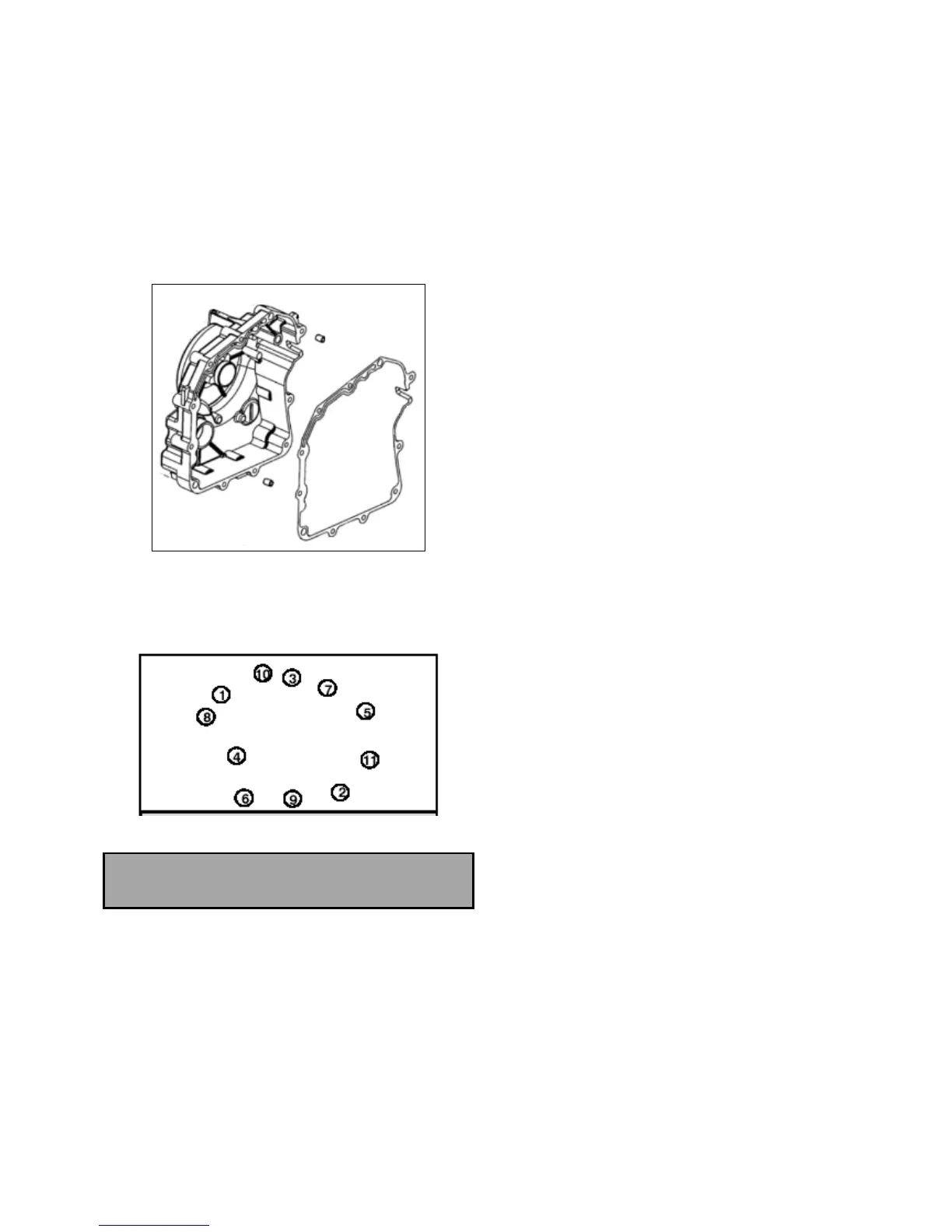

2. Seal stator wire grommet with Crankcase Sealant.

3. Install the housing. Torque bolts in sequence to

specification.

Stator Cover Bolt Torque:

8 Nm (6 ft. lbs.)

Loading...

Loading...