STARTER BRUSH INSPECTION /

REPLACEMENT

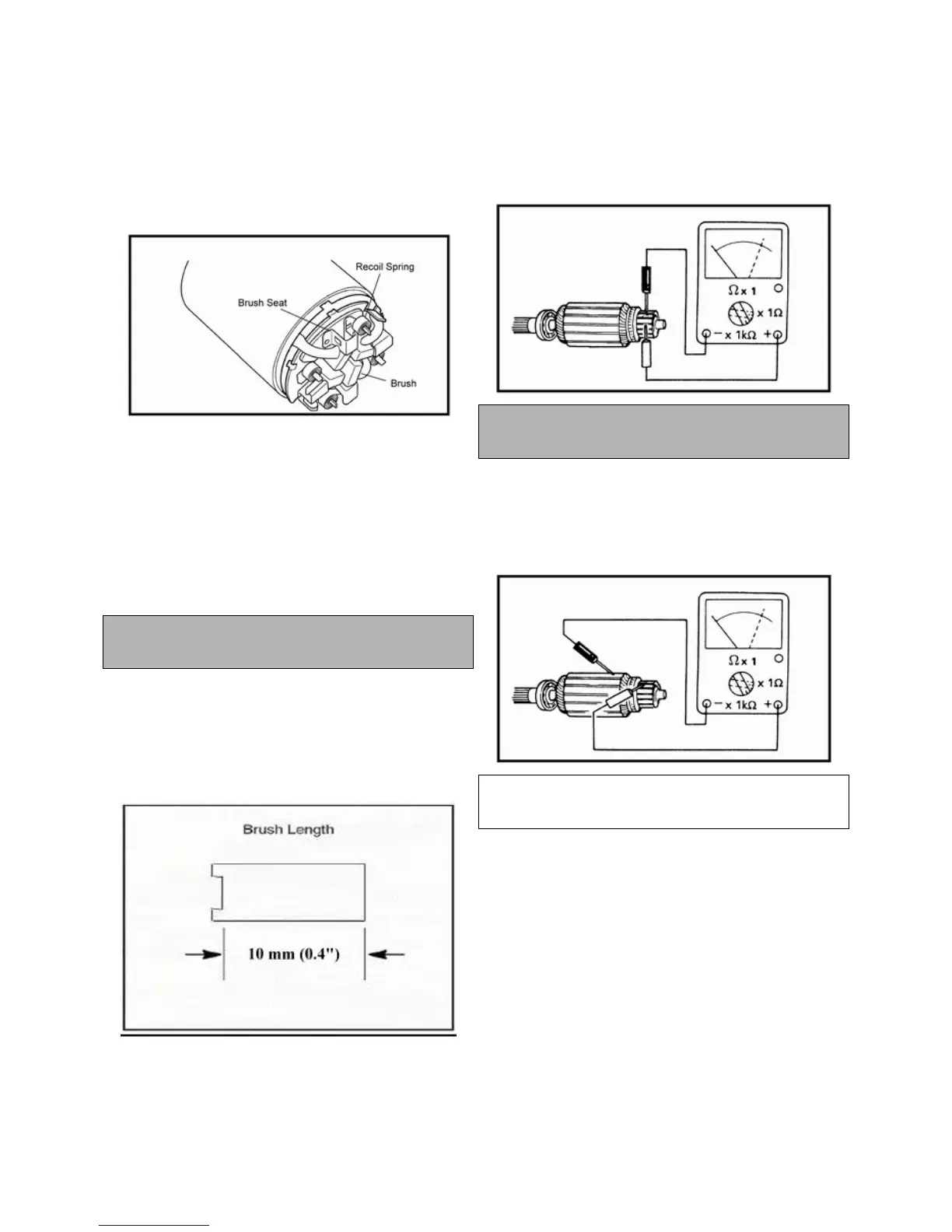

1. Release the brush coil spring away.

2. Push the armature out of case.

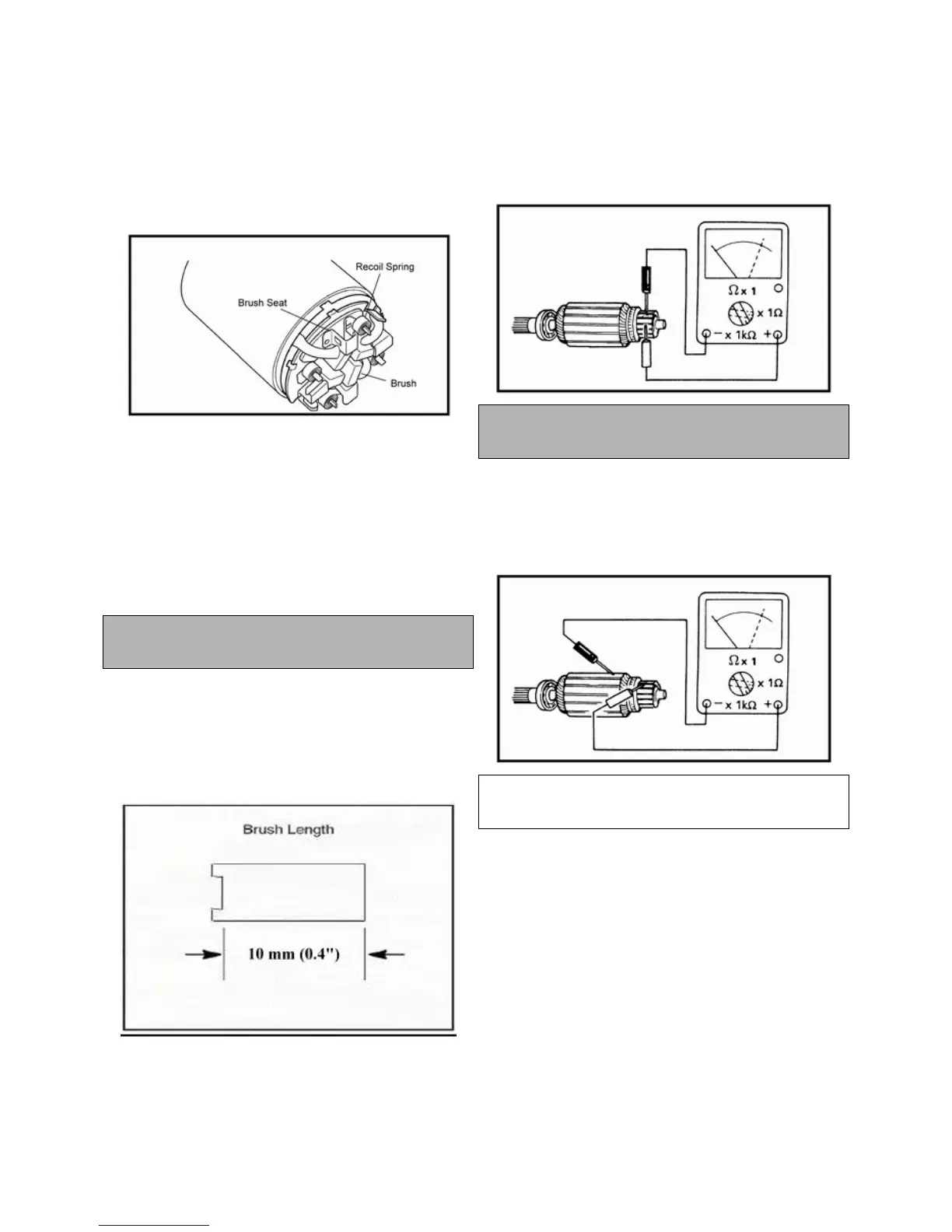

3. Using an Ohmmeter, measure the resistance between the

cable terminal and the insulated brush. The reading should

be .3 ohms or less. Measure the resistance between the cable

terminal and brush housing. Make sure the brush is not

touching the case. The reading should be infinite (no reading).

4. Remove the brush plate and brushes. Measure the brush

length and replace if worn past the service limit.

Brush Length Service Limit

10 mm (0.40“)

5. Inspect the surface of the communicator for wear or

discoloration. See Armature Test.

4. Be sure that the terminal bolt insulation washer is properly

seated in the housing and the tab on the brush plate engages

the notch in the brush plate housing.

ARMATURE TEST

1. Inspect surface of communicator. Replace if excessively

worn or damaged.

2. Using a digital multi-tester, measure the resistance between

each of the communicator segments. The reading should be

3 ohms or less.

Armature coil resistance Continuity

Less 3Ω

ΩΩ

Ωat 20 °C (68 °F)

4. Measure the resistance between each communicator

segment

(No continuity)

Insulation check

InfiniteΩ

ΩΩ

Ω at 20 °C (68 °F)

5. Check communicator bars for discoloration. Bars discolored

in pairs indicate shorted coils, requiring replacement of the

starter motor.

6. Place armature in a growler. Turn growler on and position

a hacksaw blade or feeler gauge lengthwise 3mm(1/8〃)

Loading...

Loading...