MAINTENANCE

2-22

COOLING SYSTEM

COOLING SYSTEM OVERVIEW

The engine coolant level is controlled, or maintained, by the

recovery system. The recovery system components are the

recovery bottle, radiator filler neck, radiator pressure cap and

connecting hose.

As coolant-operating temperature increases, the expanding

(heated) excess coolant is forced out of the radiator past the

pressure cap and into the recovery bottle. As engine coolant

temperature decreases the contracting (cooled) coolant is

drawn back up from the tank past the pressure cap and into the

radiator.

NOTE: Some coolant level drop on new machines is

normal as the system is purging itself of trapped air.

Observe coolant levels often during the break-in

period.

NOTE: Overheating of engine could occur if air is

fully purged from system.

Coolant 50/50 is already premixed and ready to use. Do not

dilute with water.

COOLANT LEVEL INSPECTION

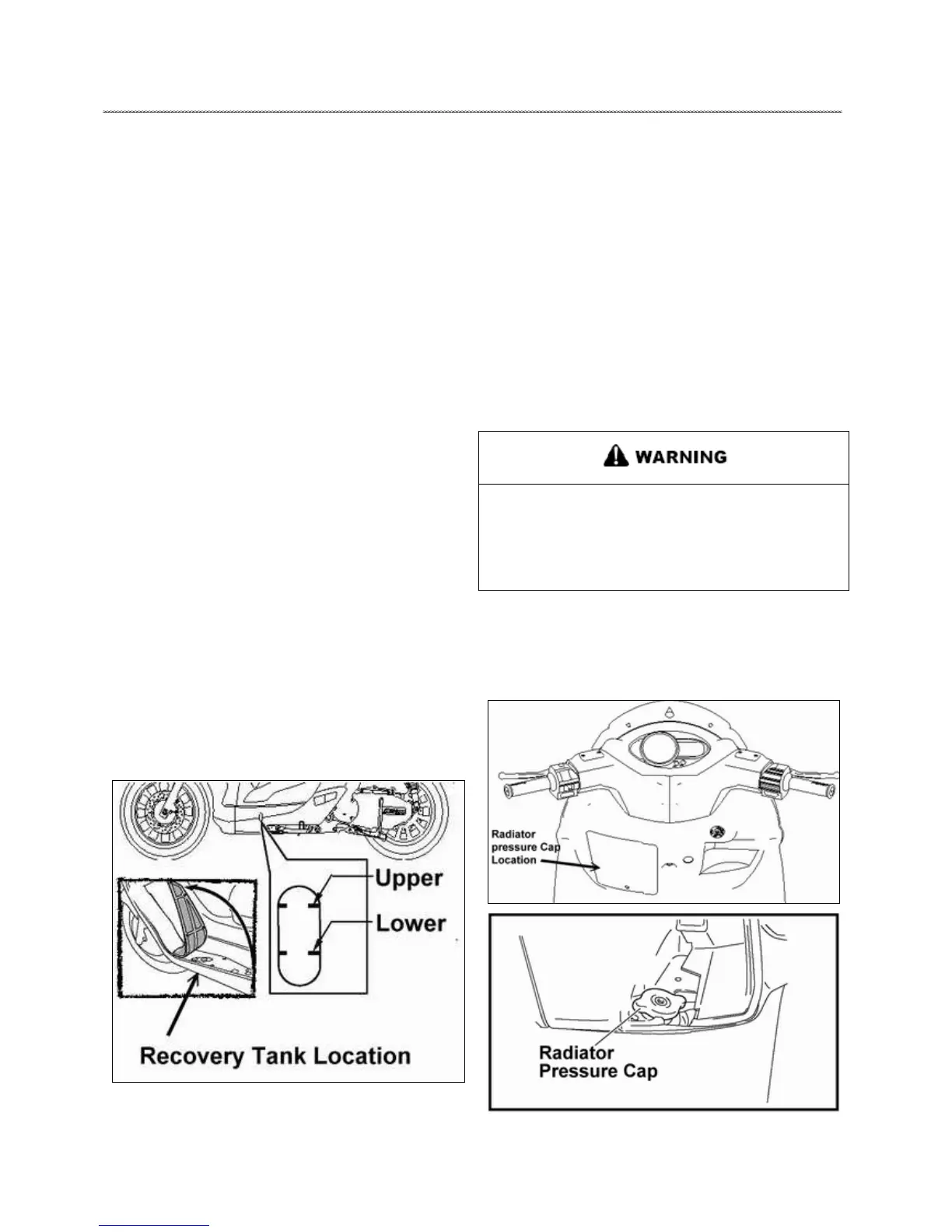

The pressure cap and recovery tank are located under the left

floor of the vehicle. The coolant level must be maintained

between the minimum and maximum levels indicated on the

recovery tank.

With the engine at operating temperature, the coolant level

should be between the upper and lower marks on the coolant

recovery bottle. If not, perform the following procedure.

1. Position the vehicle on a level surface.

2. Remove the rubber mat from the left floor.

3. View the coolant level in the recovery bottle.

4. If the coolant level is below the MIN line, inspect the

coolant level in the radiator.

NOTE: If overheating is evident, allow system to cool

completely and check coolant level in the radiator

and inspect for signs of trapped air in system.

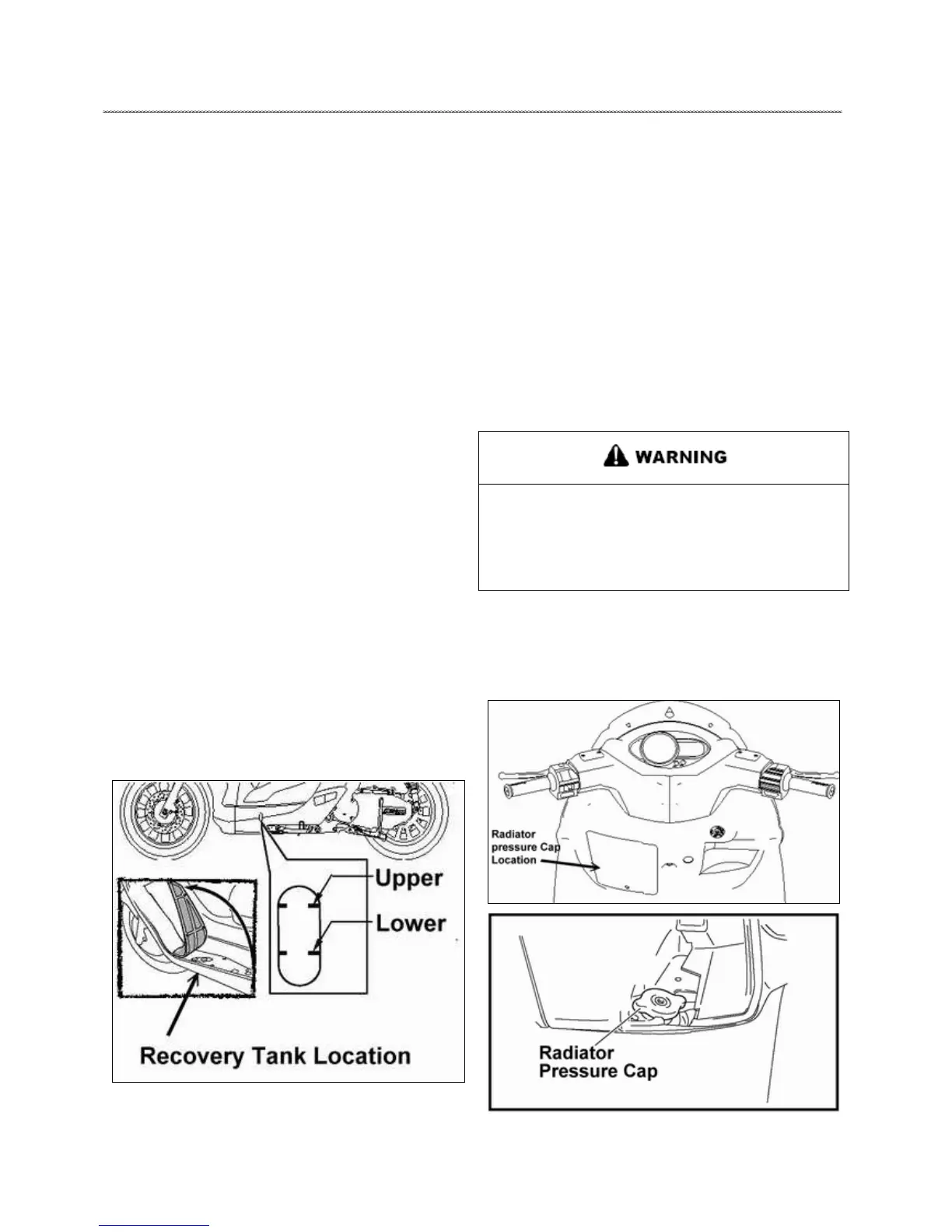

Never remove the pressure cap when the engine is

warm or hot. Escaping steam can cause severe

burns. The engine must be cool

pressure cap.

5. Remove the inspection cover from the cab.

6. Remove the pressure cap. Using a funnel, add coolant to the

top of the filler neck.

7. Reinstall the pressure cap.

Loading...

Loading...